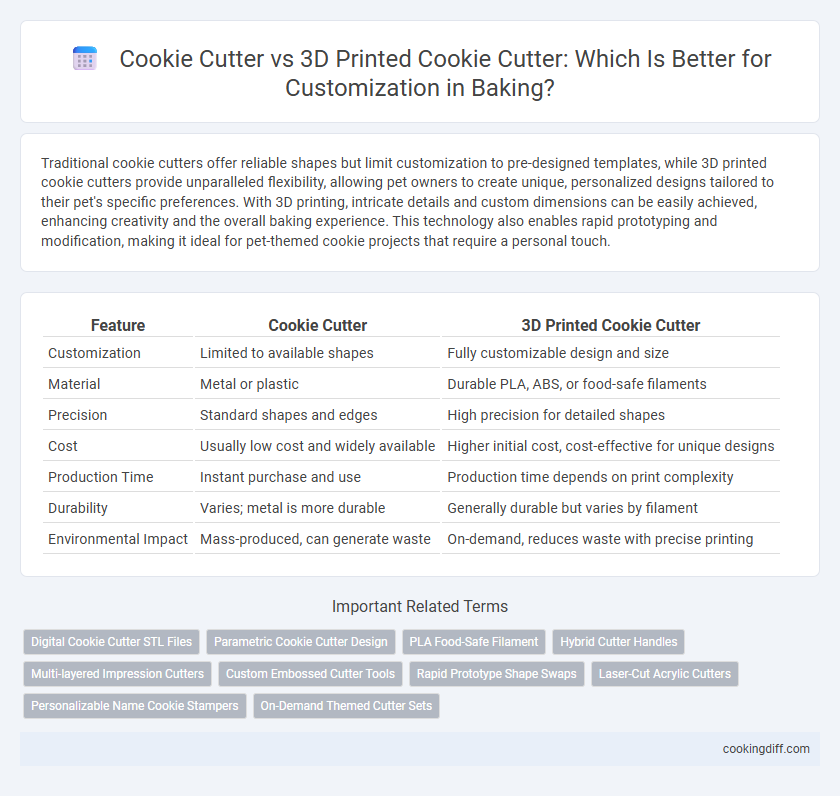

Traditional cookie cutters offer reliable shapes but limit customization to pre-designed templates, while 3D printed cookie cutters provide unparalleled flexibility, allowing pet owners to create unique, personalized designs tailored to their pet's specific preferences. With 3D printing, intricate details and custom dimensions can be easily achieved, enhancing creativity and the overall baking experience. This technology also enables rapid prototyping and modification, making it ideal for pet-themed cookie projects that require a personal touch.

Table of Comparison

| Feature | Cookie Cutter | 3D Printed Cookie Cutter |

|---|---|---|

| Customization | Limited to available shapes | Fully customizable design and size |

| Material | Metal or plastic | Durable PLA, ABS, or food-safe filaments |

| Precision | Standard shapes and edges | High precision for detailed shapes |

| Cost | Usually low cost and widely available | Higher initial cost, cost-effective for unique designs |

| Production Time | Instant purchase and use | Production time depends on print complexity |

| Durability | Varies; metal is more durable | Generally durable but varies by filament |

| Environmental Impact | Mass-produced, can generate waste | On-demand, reduces waste with precise printing |

Introduction to Cookie Cutters and Customization

Traditional cookie cutters are typically made from metal or plastic and offer standard shapes for baking enthusiasts. Customization is limited to the available designs, restricting unique creative expressions.

3D printed cookie cutters provide precise, tailor-made shapes, allowing bakers to personalize their tools for special occasions or branding. This technology enables intricate designs that are difficult to achieve with conventional cutters.

Traditional Cookie Cutters: Materials and Methods

Traditional cookie cutters are commonly made from materials such as stainless steel, tin, or plastic, offering durability and ease of use. These cutters rely on established manufacturing methods like stamping or molding, ensuring consistent shapes and thicknesses. While they provide quick and reliable cookie shaping, customization options are limited compared to 3D printed alternatives.

3D Printed Cookie Cutters: Innovation in Baking

3D printed cookie cutters offer unparalleled customization options, allowing bakers to create intricate and unique designs tailored to specific themes or events. Unlike traditional cookie cutters, 3D printing enables rapid prototyping and production of complex shapes that are difficult to achieve with standard metal or plastic cutters.

The use of food-safe materials in 3D printing ensures safety and durability for repeated use in baking. This innovation not only enhances creativity but also streamlines the customization process, making personalized baking more accessible to enthusiasts and professionals alike.

Design Possibilities: Standard vs. Custom Shapes

Which offers more design possibilities for customized baking: traditional cookie cutters or 3D printed cookie cutters? Standard cookie cutters typically come in basic, mass-produced shapes limiting creative expression. 3D printed cookie cutters enable intricate, personalized designs tailored to specific themes or events, expanding customization options for bakers.

Ease of Use and Detailing Precision

| Cookie Cutter | Traditional cookie cutters offer straightforward ease of use with basic shapes but lack intricate detailing precision, making them suitable for simple designs. |

| 3D Printed Cookie Cutter | 3D printed cookie cutters provide high detailing precision and customizable shapes, enhancing design complexity while maintaining user-friendly handling for personalized baking. |

Durability and Lifespan Comparison

Traditional cookie cutters, often made from metal or sturdy plastic, typically offer higher durability and a longer lifespan compared to many 3D printed options. However, advances in 3D printing materials like PETG or ABS improve the durability of customized cookie cutters, making them more competitive for repeated use.

- Material Strength - Metal cookie cutters resist bending and wear better than most standard 3D printed PLA models.

- Customization Longevity - 3D printed cutters made from durable filaments like ABS can withstand frequent use but may degrade faster with exposure to heat.

- Maintenance - Traditional cookie cutters require minimal upkeep, while 3D printed ones may need careful cleaning to avoid brittleness over time.

Cost Analysis: Traditional vs. 3D Printed Cutters

Traditional cookie cutters typically involve higher upfront costs due to manufacturing and material expenses, while 3D printed cutters offer a more cost-effective alternative for small batches and custom designs. The versatility and low production cost of 3D printing enable bakers to create intricate, personalized shapes without significant investment.

- Material costs - Traditional cutters often use metal or plastic molds that are more expensive to produce than 3D printer filament.

- Customization expense - 3D printing allows for unlimited design variations without incurring additional tooling fees.

- Production time - 3D printing can be slower per unit but reduces the need for mass production to achieve cost efficiency.

For bakers seeking flexibility and affordability in custom cookie shapes, 3D printed cutters present a significant cost advantage over traditional methods.

Safety and Food-Grade Considerations

Traditional cookie cutters are typically made from stainless steel or food-safe plastic, ensuring they meet established safety standards. 3D printed cookie cutters require careful selection of food-grade filaments like PLA and thorough post-processing to avoid contamination risks.

- Material Safety - Stainless steel and approved plastics are inherently food-safe, while 3D printing filaments must be certified for food contact.

- Surface Porosity - Traditional cutters have smooth surfaces that reduce bacterial buildup, whereas 3D printed cutters may have microscopic grooves that harbor bacteria.

- Regulatory Compliance - Commercial cookie cutters often comply with FDA or EU food safety regulations, whereas 3D printed cutters rely on user awareness of material safety and printer cleanliness.

Speed and Accessibility of Custom Designs

Traditional cookie cutters offer quick use but limit design customization due to standard shapes. 3D printed cookie cutters enable rapid creation of unique, intricate designs tailored to personal preferences.

3D printing technology makes custom cookie cutter production accessible to home bakers and professionals alike by reducing costs and lead times. Users can easily modify digital files to create multiple design variations without waiting for factory molds. This flexibility supports faster iteration and personalized baking experiences.

Related Important Terms

Digital Cookie Cutter STL Files

Digital cookie cutter STL files provide unparalleled customization by enabling bakers to create intricate and personalized shapes through 3D printing technology, surpassing the limitations of traditional cookie cutters. This approach allows rapid iteration, precise detailing, and on-demand production, making it ideal for unique baking projects and custom orders.

Parametric Cookie Cutter Design

Parametric cookie cutter design enables precise customization by allowing adjustable dimensions and intricate patterns typically unattainable with traditional cookie cutters. Utilizing 3D printing technology, these flexible designs can be rapidly produced with high accuracy, offering personalized shapes and sizes that enhance creative baking experiences.

PLA Food-Safe Filament

PLA food-safe filament enables the creation of highly customizable 3D printed cookie cutters, offering intricate designs and precise detail that traditional cookie cutters cannot achieve. Unlike mass-produced plastic cutters, PLA is biodegradable and non-toxic, ensuring safe contact with dough while supporting eco-friendly baking practices.

Hybrid Cutter Handles

Hybrid cutter handles combine traditional cookie cutter durability with 3D printed customization, offering precise grips tailored to intricate designs. These handles enhance user control and comfort while enabling unique shapes that standard cutters cannot achieve, optimizing both functionality and creative expression in baking.

Multi-layered Impression Cutters

Multi-layered impression cutters offer intricate designs with precise depth variations that traditional cookie cutters often cannot achieve, enhancing the visual appeal of baked goods. 3D printed cookie cutters enable customizable, complex multi-layered impressions tailored to specific themes or logos, providing bakers unmatched creative flexibility compared to standard metal or plastic cutters.

Custom Embossed Cutter Tools

Custom embossed cookie cutter tools enable precise, intricate designs that standard cookie cutters often cannot achieve, enhancing personalization and brand identity in baked goods. 3D printed cookie cutters offer rapid prototyping and detailed customization, allowing for unique shapes and textures tailored to specific themes or customer preferences.

Rapid Prototype Shape Swaps

Traditional cookie cutters offer limited design flexibility, while 3D printed cookie cutters enable rapid prototype shape swaps, allowing bakers to customize intricate and unique cookie designs quickly. This digital fabrication method reduces turnaround times and supports easy modifications, enhancing creative freedom in baking customization.

Laser-Cut Acrylic Cutters

Laser-cut acrylic cutters offer precise, sharp edges that ensure consistent cookie shapes, ideal for detailed designs compared to the flexibility of 3D printed cookie cutters, which allow for customizable, intricate patterns that can be rapidly prototyped and adjusted. The durability and smooth finish of laser-cut acrylic provide clean cuts and repeatability, while 3D printing excels in creating unique, personalized cookie cutter shapes tailored to specific themes or events.

Personalizable Name Cookie Stampers

Personalizable name cookie stampers created with 3D printing technology offer unmatched customization, allowing intricate designs and precise letter embossing that traditional cookie cutters cannot achieve. This precision enhances personalization options, making each cookie uniquely tailored to individual names or messages for special occasions.

Cookie cutter vs 3D printed cookie cutter for customization. Infographic

cookingdiff.com

cookingdiff.com