Choosing between a cooling rack and a stackable cooling grid for baked goods depends on space and airflow needs. A cooling rack provides ample air circulation for even cooling and crisping, while a stackable cooling grid maximizes vertical space, allowing multiple trays without sacrificing airflow. Both options ensure baked goods cool properly, but stackable grids are ideal for limited counter space and larger batches.

Table of Comparison

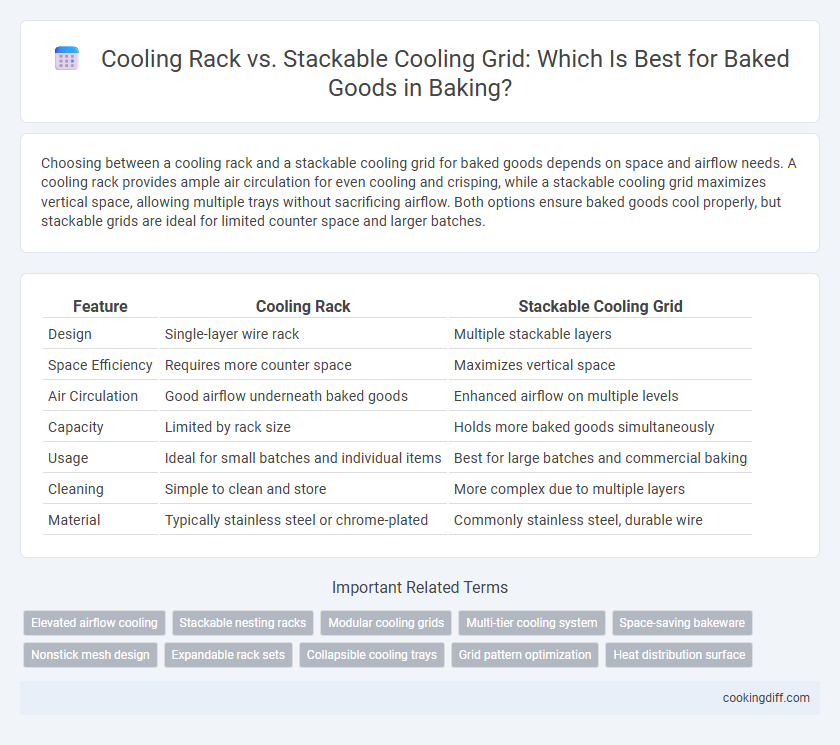

| Feature | Cooling Rack | Stackable Cooling Grid |

|---|---|---|

| Design | Single-layer wire rack | Multiple stackable layers |

| Space Efficiency | Requires more counter space | Maximizes vertical space |

| Air Circulation | Good airflow underneath baked goods | Enhanced airflow on multiple levels |

| Capacity | Limited by rack size | Holds more baked goods simultaneously |

| Usage | Ideal for small batches and individual items | Best for large batches and commercial baking |

| Cleaning | Simple to clean and store | More complex due to multiple layers |

| Material | Typically stainless steel or chrome-plated | Commonly stainless steel, durable wire |

Introduction to Cooling Racks and Stackable Cooling Grids

Cooling racks and stackable cooling grids are essential tools for properly cooling baked goods, preventing sogginess by allowing air circulation. Each type offers unique benefits suited for different baking needs and kitchen spaces.

- Cooling Rack - A flat, single-layer grid designed for even air flow beneath baked items.

- Stackable Cooling Grid - Multiple tiers of grids that save space while cooling larger batches simultaneously.

- Material Composition - Both are typically made from stainless steel or coated metal for durability and easy cleaning.

Key Differences Between Cooling Racks and Stackable Grids

Cooling racks are typically flat, single-layer grids designed to allow air circulation around baked goods, preventing sogginess and promoting even cooling. Stackable cooling grids offer the advantage of vertical storage, enabling multiple trays of baked goods to cool simultaneously in a compact space.

Cooling racks generally provide more direct airflow due to their open wire design, enhancing moisture evaporation from cookies, cakes, and bread. In contrast, stackable cooling grids prioritize space efficiency but may slightly reduce airflow to lower layers, making them ideal for high-volume baking environments.

Material and Construction Comparison

Cooling racks are typically made from stainless steel or chrome-plated steel, offering durability and resistance to rust, while stackable cooling grids often feature lightweight materials like chrome or non-stick coated metal for easy stacking and space-saving. The construction of cooling racks generally includes a single-level wire grid that ensures maximum airflow around baked goods, whereas stackable cooling grids are designed with multiple tiers and reinforced supports to maintain stability when layered. Both options provide efficient cooling, but material thickness and coating quality significantly influence longevity and ease of cleaning in professional or home baking environments.

Space Efficiency in Home Kitchens

Stackable cooling grids maximize vertical space, allowing multiple layers of baked goods to cool simultaneously without overcrowding countertops. Their compact design is ideal for small home kitchens where surface area is limited.

Cooling racks, while effective for airflow, often require more countertop space as they lie flat, limiting the number of items that can cool at once. Choosing stackable grids enhances space efficiency, enabling bakers to cool larger batches without sacrificing kitchen organization.

Air Circulation and Even Cooling

Cooling racks provide superior air circulation by elevating baked goods, allowing heat to dissipate evenly from all sides. Stackable cooling grids maximize space efficiency but may restrict airflow between layers, potentially affecting uniform cooling.

- Cooling Rack Airflow - Elevated design enhances air movement around each item, promoting faster and more even cooling.

- Stackable Grid Space Efficiency - Multiple layers allow cooling of large batches without occupying extensive counter space.

- Cooling Uniformity - Single-tier racks offer more consistent temperature distribution compared to stacked grids where lower layers may cool slower.

Versatility for Different Baked Goods

Which cooling option offers greater versatility for different baked goods: a cooling rack or a stackable cooling grid? A stackable cooling grid allows for cooling multiple layers of baked goods simultaneously, maximizing space and airflow around each item. Cooling racks typically provide a single layer of ventilation, better suited for larger cakes or bread loaves that require more surface contact.

Cleaning and Maintenance Considerations

Cooling racks and stackable cooling grids differ significantly in their cleaning and maintenance requirements, impacting overall convenience in the kitchen. Cooling racks are usually simpler to clean due to their open wire design, whereas stackable cooling grids can trap crumbs in layers, necessitating more thorough cleaning.

- Cooling Rack Simplicity - Their single-layered structure allows easy access for scrubbing and dishwasher compatibility.

- Stackable Grid Complexity - Multiple layers create tight spaces where residue and grease accumulate, requiring detailed attention.

- Material Durability - Stainless steel cooling racks resist rust and are easy to maintain, while some stackable grids made from coated materials may wear down over time.

Choosing between the two depends on your priority for ease of cleaning versus space-saving utility.

Durability and Longevity of Each Option

| Cooling Rack | Stackable Cooling Grid |

|---|---|

| Typically made from stainless steel or chrome-plated steel, offering high resistance to rust and warping, ensuring durability over years of heavy use. The solid construction withstands frequent cleaning and heat exposure without degradation. Ideal for single-level cooling with excellent longevity in professional and home baking environments. | Constructed primarily from coated steel or reinforced plastic, which may be less resistant to long-term heat and moisture exposure. Stackable design saves space but can introduce stress points at joints, potentially reducing lifespan under heavy or repeated use. Longevity depends on material quality, with stainless steel options providing better durability compared to budget plastic versions. |

Ideal Uses: When to Choose Each Type

Cooling racks are ideal for single-layer baked goods like cookies or pastries that require even air circulation on all sides to prevent sogginess. Stackable cooling grids suit smaller kitchens or large batches since they maximize vertical space without compromising airflow.

Choose a cooling rack when baking delicate items that need gentle, consistent cooling to maintain texture and avoid moisture buildup. Stackable cooling grids work best for bread, cakes, or multiple trays of baked goods that demand efficient space management during cooling. Both options should offer sturdy construction and easy cleaning to support effective baking workflows.

Related Important Terms

Elevated airflow cooling

A cooling rack with elevated legs provides superior airflow beneath baked goods, promoting even cooling and preventing sogginess by allowing steam to escape effectively. Stackable cooling grids maximize space efficiency but may restrict airflow between layers, potentially slowing the cooling process and affecting texture.

Stackable nesting racks

Stackable nesting racks maximize baking efficiency by allowing multiple layers of baked goods to cool simultaneously while conserving countertop space. Their modular design promotes optimal air circulation around each layer, enhancing uniform cooling and preventing soggy bottoms.

Modular cooling grids

Modular cooling grids offer a versatile solution compared to traditional cooling racks by allowing bakers to customize the size and configuration to accommodate varying quantities of baked goods. These stackable grids maximize airflow around pastries and breads, accelerating cooling times while saving counter space in professional and home kitchens.

Multi-tier cooling system

A multi-tier cooling system with stackable cooling grids maximizes airflow around baked goods, allowing efficient cooling in limited countertop space compared to a single-layer cooling rack. Stackable grids provide vertical storage and even heat dissipation, preventing soggy bottoms and maintaining texture during the cooling process.

Space-saving bakeware

Stackable cooling grids maximize vertical space by allowing multiple layers of baked goods to cool simultaneously, ideal for small kitchens and bulk baking. Traditional cooling racks provide single-layer airflow but occupy more countertop area, making them less efficient for space-saving bakeware solutions.

Nonstick mesh design

Nonstick mesh design in cooling racks improves airflow and prevents baked goods from sticking, ensuring even cooling and maintaining texture. Stackable cooling grids with nonstick surfaces optimize space while allowing multiple layers of pastries to cool efficiently without compromising air circulation.

Expandable rack sets

Expandable cooling rack sets offer versatile options for cooling baked goods, with stackable designs maximizing vertical space and increasing capacity without compromising airflow. Unlike traditional single-layer cooling racks, expandable stackable grids allow bakers to efficiently cool multiple batches simultaneously, enhancing kitchen organization and baking productivity.

Collapsible cooling trays

Collapsible cooling trays offer space-efficient storage and easy transport compared to traditional cooling racks, while maintaining optimal air circulation essential for evenly cooling baked goods. Stackable cooling grids maximize vertical cooling space in limited kitchens, but collapsible trays provide added convenience by folding flat for compact storage, ideal for bakers with limited counter space.

Grid pattern optimization

Grid pattern optimization in cooling racks plays a crucial role in maximizing air circulation and preventing sogginess in baked goods, with stackable cooling grids featuring smaller, more evenly spaced grids ideal for supporting delicate pastries. Cooling racks with larger grid patterns offer better airflow for items like bread and cookies but may not provide adequate support for smaller or softer baked goods.

Cooling rack vs stackable cooling grid for baked goods Infographic

cookingdiff.com

cookingdiff.com