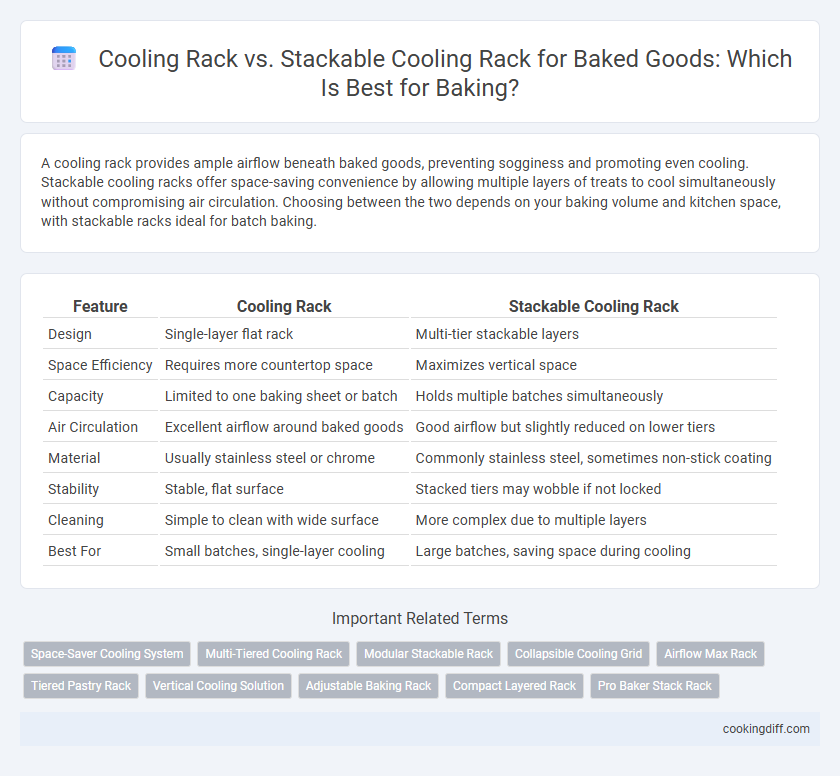

A cooling rack provides ample airflow beneath baked goods, preventing sogginess and promoting even cooling. Stackable cooling racks offer space-saving convenience by allowing multiple layers of treats to cool simultaneously without compromising air circulation. Choosing between the two depends on your baking volume and kitchen space, with stackable racks ideal for batch baking.

Table of Comparison

| Feature | Cooling Rack | Stackable Cooling Rack |

|---|---|---|

| Design | Single-layer flat rack | Multi-tier stackable layers |

| Space Efficiency | Requires more countertop space | Maximizes vertical space |

| Capacity | Limited to one baking sheet or batch | Holds multiple batches simultaneously |

| Air Circulation | Excellent airflow around baked goods | Good airflow but slightly reduced on lower tiers |

| Material | Usually stainless steel or chrome | Commonly stainless steel, sometimes non-stick coating |

| Stability | Stable, flat surface | Stacked tiers may wobble if not locked |

| Cleaning | Simple to clean with wide surface | More complex due to multiple layers |

| Best For | Small batches, single-layer cooling | Large batches, saving space during cooling |

Overview: Cooling Rack vs Stackable Cooling Rack

Cooling racks are essential for allowing baked goods to cool evenly by promoting air circulation around the product. Stackable cooling racks maximize vertical space in the kitchen, enabling multiple layers of baked items to cool simultaneously without overcrowding. Both types enhance cooling efficiency, but stackable racks are ideal for large batches or limited counter space.

Key Features of Standard Cooling Racks

Standard cooling racks provide a flat, open grid design that allows air to circulate evenly around baked goods, preventing sogginess. These racks are typically made of metal with non-stick coating to facilitate easy cleaning and durability.

- Flat Grid Surface - Ensures uniform cooling by allowing maximum air circulation beneath and around the baked items.

- Non-Stick Coating - Prevents delicate cakes and cookies from sticking, making removal easier and cleaner.

- Sturdy Construction - Offers strong support for heavy or multiple baked goods without bending or warping.

Standard cooling racks are ideal for single-layer cooling but lack the space-saving capacity of stackable designs.

Key Features of Stackable Cooling Racks

Stackable cooling racks maximize countertop space by allowing multiple layers of baked goods to cool simultaneously, making them ideal for large batches. Their sturdy, interlocking design ensures stability and even air circulation to prevent sogginess and preserve texture.

Constructed from durable stainless steel or chrome-plated materials, stackable racks are resistant to rust and easy to clean. Adjustable height settings accommodate various types of baked goods, from cookies to cakes, enhancing baking efficiency.

Space Efficiency and Storage Comparison

Cooling racks provide ample airflow for baked goods to cool evenly, but they often occupy more countertop space due to their flat, single-layer design. Stackable cooling racks optimize space by allowing multiple layers of baked items to cool simultaneously without expanding the footprint.

Stackable racks are ideal for small kitchens or bakeries with limited storage, as they can be stored vertically and save significant cabinet or shelf space. In contrast, traditional cooling racks require more horizontal clearance, making them less convenient for compact storage environments.

Air Circulation and Cooling Performance

Which cooling rack offers better air circulation for baked goods, a traditional cooling rack or a stackable cooling rack? A stackable cooling rack enhances air circulation by allowing multiple layers of baked goods to cool simultaneously without compromising airflow. This design improves cooling performance and prevents sogginess by promoting even heat dissipation around each item.

Versatility for Different Baked Goods

A stackable cooling rack offers enhanced versatility by allowing multiple layers of baked goods to cool simultaneously without compromising air circulation. This design is ideal for bakeries or home bakers handling large batches of cookies, cakes, or muffins.

Traditional cooling racks provide a single layer of cooling space, which can limit the quantity of baked items cooled at one time. Stackable racks maximize vertical space, making them perfect for ovens or kitchens with limited countertop room. They efficiently accommodate various shapes and sizes of baked goods, ensuring even cooling and preventing sogginess.

Cleaning and Maintenance Differences

Cooling racks typically have a simple, open wire design that makes cleaning straightforward and quick, whereas stackable cooling racks feature multiple tiers that can complicate access to some surfaces. Stackable racks often require more thorough attention to ensure no crumbs or residue get trapped between layers, increasing maintenance time.

- Cooling Rack Ease of Cleaning - Open wire grids allow easy rinsing and scrubbing with minimal effort.

- Stackable Cooling Rack Design Complexity - Multiple tiers create tight spaces that need careful cleaning to avoid buildup.

- Maintenance Frequency - Stackable racks generally need more frequent deep cleaning to maintain hygiene.

Durability and Material Options

| Cooling Rack Type | Durability | Material Options |

|---|---|---|

| Cooling Rack | Standard cooling racks are typically made from stainless steel or chrome-plated steel, offering moderate durability resistant to rust and bending under typical baking use. | Common materials include stainless steel, chrome-plated steel, and occasionally aluminum, each providing different levels of strength and heat resistance. |

| Stackable Cooling Rack | Stackable cooling racks are engineered for both durability and stability, often constructed from heavy-duty stainless steel to support multiple layers of baked goods without warping or collapsing. | Heavier gauge stainless steel and sometimes non-stick coated steel are used to enhance longevity and ease of cleaning, making them suitable for commercial and high-volume baking environments. |

Pros and Cons: Traditional vs Stackable Racks

Traditional cooling racks offer ample airflow and easy access but can take up significant counter space. Stackable cooling racks maximize vertical space, allowing multiple trays to cool simultaneously in a compact area.

- Traditional Cooling Rack - Provides excellent air circulation around baked goods for even cooling.

- Stackable Cooling Rack - Saves countertop space by allowing multiple layers of cooling trays.

- Stackable Cooling Rack - May reduce airflow to lower racks, potentially slowing the cooling process.

Related Important Terms

Space-Saver Cooling System

Stackable cooling racks maximize vertical space in kitchens, allowing bakers to cool multiple trays of baked goods simultaneously without sacrificing countertop area. Unlike traditional single-layer cooling racks, these space-saver systems promote efficient airflow between tiers, accelerating the cooling process while maintaining product quality.

Multi-Tiered Cooling Rack

A multi-tiered cooling rack optimizes kitchen space by allowing multiple layers of baked goods to cool simultaneously, ensuring even airflow and faster cooling. Unlike traditional flat racks, stackable cooling racks improve efficiency in baking processes, especially for large batches or small kitchens.

Modular Stackable Rack

Modular stackable cooling racks maximize kitchen efficiency by allowing multiple layers of baked goods to cool simultaneously, saving valuable counter space while promoting optimal air circulation for faster cooling. These versatile racks, made from durable materials like stainless steel or coated steel, support heavy loads and are easily adjustable to accommodate various baked goods sizes and quantities.

Collapsible Cooling Grid

Collapsible cooling grids offer enhanced space efficiency compared to traditional cooling racks by allowing easy folding for compact storage while maintaining adequate airflow to prevent sogginess in baked goods. Stackable cooling racks, often incorporating collapsible designs, maximize vertical space in busy kitchens, enabling multiple batches to cool simultaneously without compromising air circulation.

Airflow Max Rack

Airflow Max Rack enhances cooling efficiency by allowing optimal airflow around baked goods, preventing sogginess and ensuring even cooling compared to traditional cooling racks. Its stackable design maximizes space without compromising ventilation, making it ideal for high-volume baking environments.

Tiered Pastry Rack

Tiered pastry racks provide a space-efficient solution for cooling multiple trays of baked goods simultaneously, enhancing airflow and reducing cooldown time compared to standard single-layer cooling racks. These stackable cooling racks feature adjustable tiers designed to maintain optimal bakery freshness while maximizing kitchen workspace.

Vertical Cooling Solution

Stackable cooling racks maximize vertical space by allowing multiple layers of baked goods to cool simultaneously, improving airflow and reducing countertop clutter. These vertical cooling solutions enhance efficiency in small kitchens or commercial bakeries by increasing capacity without sacrificing proper air circulation essential for preventing sogginess.

Adjustable Baking Rack

An adjustable baking rack enhances airflow around baked goods compared to traditional cooling racks, promoting even cooling and preventing sogginess. Its stackable feature maximizes kitchen space by allowing multiple layers of cooling without compromising stability or air circulation.

Compact Layered Rack

A compact layered cooling rack maximizes kitchen space by allowing multiple tiers for baked goods to cool simultaneously without crowding, improving airflow and cooling efficiency compared to single-layer racks. Stackable cooling racks offer versatile, space-saving solutions ideal for bakers needing to cool large batches while maintaining optimal surface contact and preventing sogginess.

Cooling Rack vs Stackable Cooling Rack for baked goods. Infographic

cookingdiff.com

cookingdiff.com