Nonstick pans offer effortless food release and easy cleanup, making them ideal for delicate baked goods like cakes and cookies. Carbon steel pans provide superior heat retention and develop a natural seasoning over time, enhancing flavor and browning in breads and pastries. Choosing between the two depends on your baking style, with nonstick best for quick, low-fat recipes and carbon steel preferred for high-heat baking and durability.

Table of Comparison

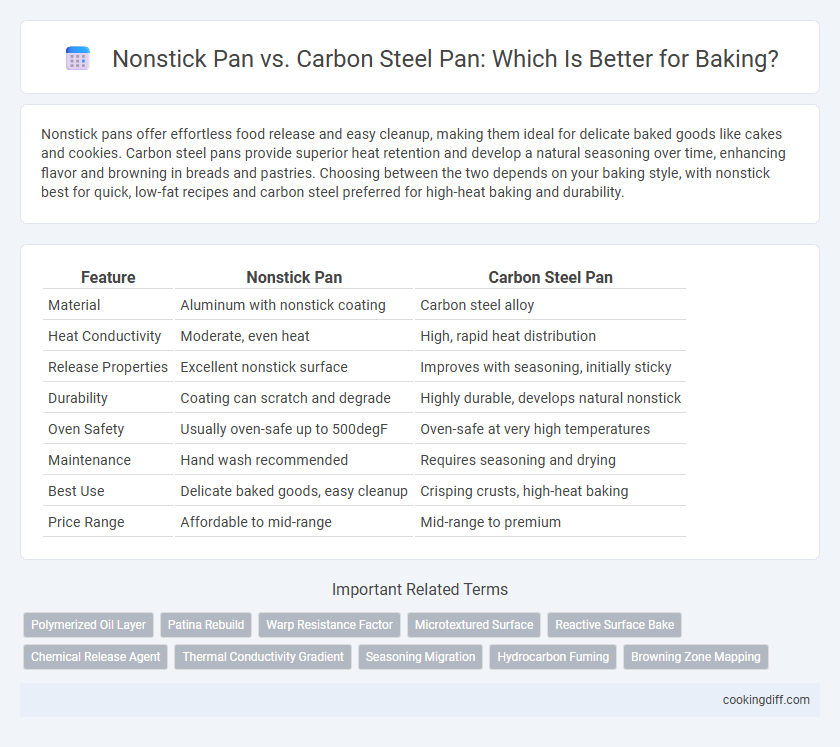

| Feature | Nonstick Pan | Carbon Steel Pan |

|---|---|---|

| Material | Aluminum with nonstick coating | Carbon steel alloy |

| Heat Conductivity | Moderate, even heat | High, rapid heat distribution |

| Release Properties | Excellent nonstick surface | Improves with seasoning, initially sticky |

| Durability | Coating can scratch and degrade | Highly durable, develops natural nonstick |

| Oven Safety | Usually oven-safe up to 500degF | Oven-safe at very high temperatures |

| Maintenance | Hand wash recommended | Requires seasoning and drying |

| Best Use | Delicate baked goods, easy cleanup | Crisping crusts, high-heat baking |

| Price Range | Affordable to mid-range | Mid-range to premium |

Introduction to Nonstick and Carbon Steel Pans for Baking

Nonstick pans offer an easy-release surface ideal for delicate baked goods, while carbon steel pans provide excellent heat retention and durability. Both types serve distinct purposes based on baking needs and maintenance preferences.

- Nonstick Pan - Coated with a synthetic material that prevents food from sticking, making cleanup simple and quick.

- Carbon Steel Pan - Made from a highly conductive metal that heats evenly and withstands high temperatures.

- Baking Performance - Nonstick pans excel for soft, fragile items, whereas carbon steel pans create a crispier crust and develop seasoning over time.

Material Composition: Nonstick vs Carbon Steel

Nonstick pans feature a synthetic coating, typically polytetrafluoroethylene (PTFE), which provides a smooth, low-friction surface ideal for delicate baked goods. Carbon steel pans consist primarily of iron alloyed with a small amount of carbon, delivering excellent heat conduction and natural nonstick properties when properly seasoned. The material composition influences durability, heat distribution, and the need for maintenance, making carbon steel suitable for high-temperature baking and nonstick pans preferable for easy release and cleanup.

Heat Distribution and Retention: Which Pan Performs Better?

Carbon steel pans offer superior heat distribution and retention compared to nonstick pans, allowing for more even baking results. Nonstick pans heat up quickly but often lack the ability to maintain consistent temperatures during longer baking sessions.

- Carbon steel heat distribution - Carbon steel conducts heat evenly across the surface, minimizing hot spots that can cause uneven baking.

- Carbon steel heat retention - Its thicker material retains heat well, ensuring steady temperatures throughout the baking process.

- Nonstick heating characteristics - Nonstick pans heat rapidly but generally lose heat quickly, potentially leading to inconsistent baking performance.

Baking Results: Texture and Browning Comparison

Which pan yields better texture and browning for baked goods? Carbon steel pans provide superior heat retention and even distribution, resulting in a crispier crust and more uniform browning. Nonstick pans prevent sticking but may produce softer textures with less intense browning due to lower heat tolerance.

Ease of Use: Handling and Maintenance Differences

Nonstick pans offer superior ease of use due to their lightweight design and effortless food release, making them ideal for beginners. Carbon steel pans require seasoning and regular maintenance to prevent rust but provide excellent heat retention and durability.

- Lightweight Design - Nonstick pans are generally lighter, allowing for easier handling during baking and cleaning.

- Maintenance Requirements - Carbon steel needs seasoning and careful drying to maintain its nonstick surface and prevent corrosion.

- Durability - Carbon steel pans last longer when properly maintained, unlike nonstick coatings that may degrade over time.

Choosing between these pans depends on your willingness to invest time in upkeep versus prioritizing convenience.

Nonstick Pan Safety Considerations

Nonstick pans, commonly coated with polytetrafluoroethylene (PTFE), offer easy food release and require less oil, making them popular for baking delicate items like cookies and cakes. However, overheating nonstick pans above 500degF can release toxic fumes harmful to humans and pets, so it's crucial to use them within recommended temperature limits.

Choosing PFOA-free nonstick coatings enhances safety, as perfluorooctanoic acid (PFOA) has been linked to health risks and is mostly phased out in modern cookware. Proper care, such as avoiding metal utensils and abrasive cleaners, prolongs the pan's lifespan and maintains the integrity of its nonstick surface for safer baking.

Carbon Steel Pan Seasoning and Care

| Carbon Steel Pan Seasoning | Seasoning a carbon steel pan involves coating it with a thin layer of oil and heating to create a natural nonstick surface that improves with use. Regular seasoning prevents rust and enhances the pan's baking performance by promoting even heat distribution and preventing food from sticking. |

| Care Tips | Clean carbon steel pans with warm water and avoid detergent to preserve the seasoning layer. Dry thoroughly and apply a light coat of oil after each use to maintain the pan's nonstick surface and prevent oxidation, ensuring durability for baking tasks. |

Versatility: Beyond Baking Applications

Nonstick pans offer exceptional versatility for baking due to their easy release surface, making them ideal for delicate items like cakes and cookies without the need for excessive greasing. Carbon steel pans provide superior heat retention and durability, making them suitable not only for baking but also for tasks like searing, roasting, and stovetop cooking. Both pan types extend functionality beyond baking, catering to a wide range of culinary techniques in the kitchen.

Price Comparison and Long-Term Value

Nonstick pans typically have a lower upfront cost, making them an affordable option for beginner bakers. Carbon steel pans generally come at a higher price point, reflecting their durability and professional-grade quality.

While nonstick pans may need replacement every few years due to coating wear, carbon steel pans improve with regular seasoning and can last a lifetime, delivering excellent long-term value. Carbon steel's versatility also allows it to withstand high oven temperatures without warping, unlike some nonstick coatings. Investing in carbon steel can reduce recurring costs, making it a cost-effective choice for frequent bakers.

Related Important Terms

Polymerized Oil Layer

Nonstick pans offer a smooth, polymerized oil layer that prevents batter from sticking and ensures easy release of baked goods, while carbon steel pans require seasoning to develop this natural nonstick surface through repeated polymerization of oils. The polymerized oil layer on carbon steel improves with use, providing a durable, chemical-free nonstick coating preferred by bakers seeking enhanced browning and flavor.

Patina Rebuild

Carbon steel pans develop a natural patina over time, enhancing nonstick properties and improving flavor profiles in baked goods, while nonstick pans rely on synthetic coatings that may degrade with use. Regular seasoning and proper maintenance of carbon steel pans rebuild the patina, providing a durable, chemical-free nonstick surface ideal for consistent baking performance.

Warp Resistance Factor

Carbon steel pans exhibit superior warp resistance compared to nonstick pans, maintaining their flat shape under high baking temperatures due to their robust, thick metal construction. Nonstick pans, often made from aluminum, tend to warp more easily when exposed to rapid temperature changes, potentially impacting baking consistency and evenness.

Microtextured Surface

A carbon steel pan with a microtextured surface promotes superior heat retention and even baking by allowing better air circulation and reducing sticking without the need for excessive oil. Nonstick pans offer a smooth surface that prevents batter adherence but can compromise browning and texture compared to the enhanced crust development provided by the microtexture of carbon steel.

Reactive Surface Bake

Nonstick pans offer a smooth, chemically inert surface that prevents batter from sticking and facilitates easy release, ideal for delicate baked goods. Carbon steel pans develop a natural seasoning layer that enhances nonstick properties but may react with acidic ingredients, potentially affecting the flavor and appearance of baked items with reactive surfaces.

Chemical Release Agent

Nonstick pans use chemical release agents like polytetrafluoroethylene (PTFE) to prevent food from sticking, which can degrade and release harmful fumes at high baking temperatures above 500degF (260degC). Carbon steel pans lack these synthetic coatings, offering a natural nonstick surface when properly seasoned, making them safer for high-heat baking without the risk of chemical exposure.

Thermal Conductivity Gradient

Nonstick pans offer moderate thermal conductivity with an even heat distribution ideal for delicate baked goods, while carbon steel pans exhibit superior thermal conductivity gradients, enabling rapid heat transfer and enhanced browning for artisanal breads and pastries. The high responsiveness of carbon steel to temperature changes provides precise control during baking, contrasting with the consistent but slower heating of nonstick surfaces.

Seasoning Migration

Carbon steel pans require regular seasoning to build a natural nonstick layer that improves with use, while nonstick pans utilize synthetic coatings that prevent seasoning migration and reduce the risk of food sticking. Seasoning migration in carbon steel pans enhances flavor development and durability, whereas nonstick pans offer consistent release and easy cleanup without the need for seasoning maintenance.

Hydrocarbon Fuming

Nonstick pans emit hydrocarbon fumes at high temperatures, potentially releasing harmful substances during baking, while carbon steel pans develop a natural seasoning that minimizes fuming and enhances heat conduction. Choosing carbon steel pans reduces hydrocarbon exposure, promoting healthier baking and durable performance over time.

Nonstick Pan vs Carbon Steel Pan for baking. Infographic

cookingdiff.com

cookingdiff.com