Traditional sifters rely on a simple mesh screen and hand-crank mechanism that gently aerates and removes lumps from flour, making them ideal for small baking tasks. Rotary flour sifters feature a rotating handle that quickly pushes flour through fine mesh, providing faster and more consistent sifting, especially useful for larger batches. Both types improve flour texture, but rotary sifters offer enhanced efficiency and ease of use for frequent baking needs.

Table of Comparison

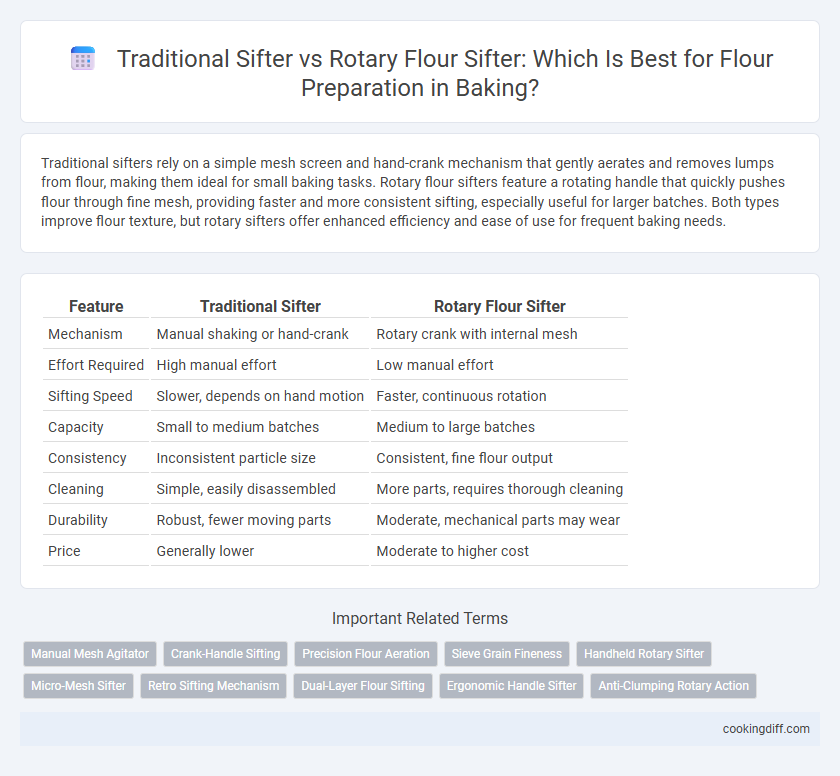

| Feature | Traditional Sifter | Rotary Flour Sifter |

|---|---|---|

| Mechanism | Manual shaking or hand-crank | Rotary crank with internal mesh |

| Effort Required | High manual effort | Low manual effort |

| Sifting Speed | Slower, depends on hand motion | Faster, continuous rotation |

| Capacity | Small to medium batches | Medium to large batches |

| Consistency | Inconsistent particle size | Consistent, fine flour output |

| Cleaning | Simple, easily disassembled | More parts, requires thorough cleaning |

| Durability | Robust, fewer moving parts | Moderate, mechanical parts may wear |

| Price | Generally lower | Moderate to higher cost |

Overview of Sifting in Baking

| Traditional sifters use a simple crank or squeeze mechanism to pass flour through a fine mesh, removing lumps and aerating the flour for lighter baked goods. Rotary flour sifters feature a rotating blade that pushes the flour through a screen, often providing faster and more consistent sifting with less manual effort. Both types improve flour texture and ensure even mixing, but rotary sifters are preferred for high-volume or frequent baking due to efficiency and ease of use. |

What Is a Traditional Flour Sifter?

A traditional flour sifter typically consists of a simple cylindrical or mesh drum with a crank handle that forces flour through a fine mesh screen. This manual device helps aerate and remove lumps from flour, ensuring an even texture for baking.

Its design is often lightweight and compact, making it easy to store and clean. Traditional sifters rely solely on mechanical force without electrical components, preserving a hands-on approach to flour preparation.

How Does a Rotary Flour Sifter Work?

A rotary flour sifter operates by turning a crank that spins a mesh screen inside the cylinder, effectively separating clumps and aerating the flour for a consistent texture. Unlike traditional sifters that require shaking or tapping, the rotary mechanism allows for faster and easier flour preparation. This design reduces hand fatigue while ensuring finely sifted flour ideal for baking delicate pastries and cakes.

Key Differences: Traditional vs Rotary Sifters

What are the key differences between traditional sifters and rotary flour sifters for flour preparation? Traditional sifters typically use a hand-crank or squeeze mechanism, offering a simple, manual process ideal for small quantities. Rotary sifters feature a rotating agitator inside, allowing faster, more consistent sifting and handling larger volumes of flour with less effort.

Sifting Efficiency and Flour Consistency

Traditional sifters provide moderate sifting efficiency but may leave some clumps in the flour, affecting baking consistency. Rotary flour sifters offer higher efficiency by evenly distributing flour through a mesh, resulting in finer, more consistent flour texture.

- Traditional Sifter Efficiency - Manual operation can limit sifting speed and thoroughness.

- Rotary Flour Sifter Consistency - Continuous rotary motion produces uniform flour particle size.

- Flour Preparation Outcome - Finer sifting improves dough texture and baking rise quality.

Choosing a rotary flour sifter enhances both sifting efficiency and flour consistency for superior baking results.

Ease of Use: Manual vs Rotary Sifters

Traditional sifters require manual shaking or tapping, which can be tiring during large baking tasks, while rotary sifters use a hand crank to effortlessly sift flour. Rotary sifters generally offer more consistent results with less physical effort, making them preferable for frequent bakers.

- Traditional Sifter Manual Operation - Requires repetitive shaking, leading to faster hand fatigue during extensive use.

- Rotary Sifter Hand Crank - Uses a crank mechanism to sift flour smoothly with minimal strain.

- Efficiency Comparison - Rotary sifters provide even flour distribution more efficiently than manual models.

Cleaning and Maintenance Comparison

Traditional sifters feature a simple crank mechanism that is easier to disassemble and clean, making them ideal for regular maintenance. Their straightforward design reduces the risk of flour buildup, ensuring consistent performance.

Rotary flour sifters often include more intricate parts, such as internal rotating meshes, which can trap flour particles and require more thorough cleaning. The added complexity means they may take longer to maintain and are prone to clogging if not cleaned properly after each use. Regular disassembly and careful washing are essential to preserve the rotary sifter's functionality and longevity.

Durability and Material Quality

Traditional sifters are often made from stainless steel or tin, providing high durability and resistance to rust, which ensures long-lasting performance in flour preparation. The simple mesh design allows easy cleaning and maintenance, enhancing material longevity over time.

Rotary flour sifters typically feature a crank mechanism with metal or plastic components, where metal models offer superior durability compared to plastic ones prone to wear. High-quality rotary sifters use stainless steel, which resists corrosion and provides consistent sifting efficiency for extended use.

Suitability for Various Baking Recipes

Traditional sifters excel in light, delicate batters where gentle aeration is essential, making them ideal for cakes and pastries. Rotary flour sifters are better suited for denser dough mixtures, such as bread or cookies, due to their efficient and thorough sifting mechanism.

- Light Batters - Traditional sifters evenly aerate flour without over-mixing, perfect for chiffon cakes and sponge cakes.

- Heavy Doughs - Rotary sifters handle larger quantities and coarser flours, supporting bread and cookie dough preparation.

- Recipe Versatility - Both types can be chosen based on the specific textural and preparation needs of different baking recipes.

Related Important Terms

Manual Mesh Agitator

Traditional sifters with a manual mesh agitator rely on simple hand-cranked mechanisms to push flour through fine mesh screens, ensuring aerated and lump-free flour for baking. Rotary flour sifters, while also manual, use a rotating paddle system that offers faster, more consistent sifting and better control over flour texture, making them ideal for precise baking needs.

Crank-Handle Sifting

Crank-handle rotary flour sifters, unlike traditional handheld sifters, use a simple mechanical crank to efficiently separate and aerate flour, resulting in a finer, more consistent texture ideal for baking delicate pastries and cakes. The enclosed design minimizes mess and speeds up the sifting process compared to the manual shaking or tapping method of traditional sifters.

Precision Flour Aeration

Traditional sifters use a simple mesh screen to aerate flour, creating a light, fluffy texture ideal for delicate baked goods, but may vary in consistency due to manual shaking. Rotary flour sifters feature a crank mechanism that ensures uniform flour aeration with precise control, enhancing batter texture and improving the accuracy of flour measurement for consistent baking results.

Sieve Grain Fineness

Traditional sifters produce variable grain fineness depending on the mesh size and manual shaking consistency, often resulting in coarser flour particles. Rotary flour sifters, equipped with a rotating blade mechanism, deliver more uniform and finer flour granules by consistently forcing flour through the sieve, enhancing dough texture and baking quality.

Handheld Rotary Sifter

Handheld rotary sifters feature a crank-operated mesh that ensures fine, evenly aerated flour for superior baking results compared to traditional sifters, which often rely on manual shaking or tapping. Their efficient design minimizes clumping and speeds up the flour preparation process, making them ideal for achieving consistent dough texture and improved rise in baked goods.

Micro-Mesh Sifter

Micro-mesh sifters provide superior flour preparation accuracy by filtering finer particles compared to traditional sifters, enhancing dough texture and consistency. Rotary flour sifters are efficient for larger batches but often lack the precision of micro-mesh technology, which ensures finer, more uniform flour distribution in baking processes.

Retro Sifting Mechanism

Traditional sifters utilize a retro sifting mechanism with a simple wire mesh and crank handle, providing coarse flour aeration suitable for rustic baking styles. Rotary flour sifters enhance efficiency by integrating a rotating blade inside a cylindrical mesh, producing finer, airier flour ideal for delicate pastries.

Dual-Layer Flour Sifting

Dual-layer flour sifters enhance baking precision by thoroughly aerating flour and removing impurities more efficiently than traditional sifters. Rotary flour sifters with dual layers offer faster, consistent sifting, reducing clumps and ensuring a light, uniform flour texture ideal for delicate baked goods.

Ergonomic Handle Sifter

The ergonomic handle sifter in rotary flour sifters provides enhanced grip and reduces hand fatigue during prolonged use compared to traditional sifters, making flour preparation more efficient. Its design allows smoother, faster flour sifting and better control, improving baking accuracy and consistency.

Traditional Sifter vs Rotary Flour Sifter for flour preparation Infographic

cookingdiff.com

cookingdiff.com