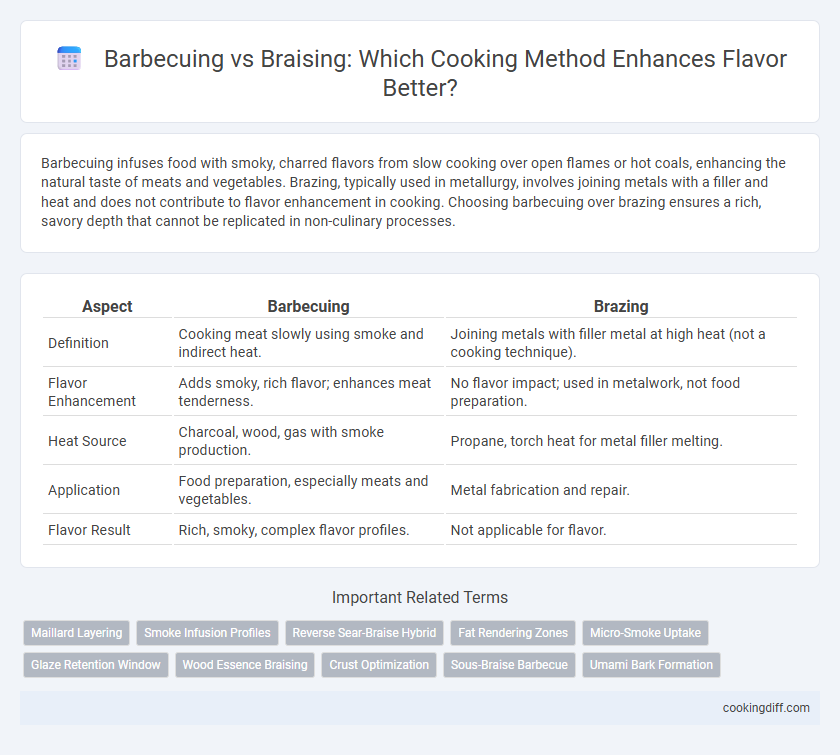

Barbecuing infuses food with smoky, charred flavors from slow cooking over open flames or hot coals, enhancing the natural taste of meats and vegetables. Brazing, typically used in metallurgy, involves joining metals with a filler and heat and does not contribute to flavor enhancement in cooking. Choosing barbecuing over brazing ensures a rich, savory depth that cannot be replicated in non-culinary processes.

Table of Comparison

| Aspect | Barbecuing | Brazing |

|---|---|---|

| Definition | Cooking meat slowly using smoke and indirect heat. | Joining metals with filler metal at high heat (not a cooking technique). |

| Flavor Enhancement | Adds smoky, rich flavor; enhances meat tenderness. | No flavor impact; used in metalwork, not food preparation. |

| Heat Source | Charcoal, wood, gas with smoke production. | Propane, torch heat for metal filler melting. |

| Application | Food preparation, especially meats and vegetables. | Metal fabrication and repair. |

| Flavor Result | Rich, smoky, complex flavor profiles. | Not applicable for flavor. |

Introduction to Barbecuing and Brazing

What distinguishes barbecuing from brazing in terms of flavor enhancement? Barbecuing employs low and slow cooking over indirect heat, infusing meats with smoky, rich flavors from wood or charcoal. Brazing, a metal-joining process, involves heating materials without direct flame and does not contribute to food flavor development.

Flavor Profiles: Barbecuing vs Brazing

Barbecuing imparts a smoky, charred flavor profile due to slow cooking over indirect heat and wood smoke, enhancing the natural taste of meats. Brazing, a metallurgical process involving melting a filler metal, does not influence flavor but rather joins metals in repair or construction. For culinary purposes, barbecuing uniquely enhances flavors through Maillard reactions and smoke absorption, which brazing cannot replicate.

Cooking Techniques: Direct Heat vs Moist Heat

Barbecuing employs direct heat, typically from charcoal or wood, to sear meat and create a smoky flavor through the Maillard reaction and caramelization. This dry heat method intensifies the meat's natural flavors while forming a crispy, flavorful crust on the surface.

Brazing uses moist heat by cooking meat slowly in liquid at lower temperatures, which tenderizes tougher cuts through collagen breakdown but results in less smoky complexity. The moist environment preserves juiciness but lacks the distinctive char and aroma achieved by barbecuing over open flames.

Ingredient Compatibility for Barbecue and Brazing

Barbecuing enhances flavor by infusing ingredients like marinated meats and vegetables with smoky aromas from wood or charcoal, which complements natural sugars and fats. The slow cooking process allows for caramelization and Maillard reactions, creating rich, complex tastes ideal for pork, beef, chicken, and hearty vegetables.

Brazing, typically used for metal joining, offers no flavor enhancement and requires materials compatible with heat and flux rather than food ingredients. Unlike barbecuing, brazing involves non-edible components such as alloys and does not interact with culinary ingredients like spices or marinades.

Smoke Infusion: The Barbecue Advantage

Barbecuing excels in smoke infusion, using direct exposure to hardwood smoke that penetrates meat fibers, enhancing flavor complexity. This process imparts a rich, smoky aroma that brazing cannot replicate due to its primarily heat-based bonding method.

Unlike brazing, which applies heat to join metals without adding flavor, barbecuing leverages controlled combustion of wood and charcoal to infuse food with diverse smoke compounds. The slow cooking at lower temperatures allows smoke particles to deeply permeate, creating a distinctive taste profile. This flavor enhancement makes barbecuing the preferred technique for culinary enthusiasts seeking authentic smoky flavors.

Moisture Retention and Tenderness Comparison

Barbecuing enhances flavor by slow-cooking meat over indirect heat, which helps retain moisture and develop tenderness through gradual collagen breakdown. Brazing, involving cooking in liquid at lower temperatures, often results in more uniformly tender meat but can cause flavor dilution and less crust formation.

- Moisture Retention in Barbecuing - The slow smoke process seals in juices by forming a flavorful bark that reduces moisture loss.

- Moisture Retention in Brazing - Slow simmering in liquid maintains internal moisture but may leach out some flavors, leading to less intense taste.

- Tenderness Comparison - Barbecuing breaks down connective tissue over time for a smoky, tender bite, while brazing achieves tenderness primarily through prolonged moist heat exposure.

Marinades and Seasonings: Impact on Flavor

Barbecuing enhances flavor through direct exposure to smoke and high heat, which caramelizes marinades and seasoning, creating a complex, smoky taste. Brazing, in contrast, involves slow cooking in liquid where marinades and seasonings infuse more subtly into the meat without smoky notes.

- Marinade Interaction - Barbecuing intensifies marinades by creating a charred outer crust that amplifies flavor.

- Flavor Penetration - Brazing allows deep infusion of seasonings throughout the meat due to prolonged liquid cooking.

- Seasoning Impact - Barbecuing transforms dry rubs and sauces through smoke and heat, producing bold, vibrant profiles.

Texture Differences Between Barbecued and Braised Dishes

| Cooking Method | Texture | Flavor Impact |

| Barbecuing | Produces a crispy, charred exterior with a tender interior due to high, direct heat exposure. | Enhances smoky, robust flavors through caramelization and Maillard reactions on the meat surface. |

| Braising | Results in soft, moist, and tender meat with a uniformly cooked texture from slow, moist heat. | Develops deep, rich flavors as the meat absorbs liquids and seasonings during slow cooking. |

Time and Temperature Control in Each Method

Barbecuing relies on low and slow cooking temperatures ranging from 225degF to 275degF over several hours, allowing smoke to penetrate and enhance flavor through controlled time and indirect heat. Brazing utilizes higher temperatures between 300degF and 400degF but for shorter durations, focusing on moisture retention through sealed cooking environments rather than smoky flavor infusion. Precise time and temperature control in barbecuing maximizes flavor complexity, while brazing prioritizes tenderness and juiciness with less emphasis on smoky taste development.

Related Important Terms

Maillard Layering

Barbecuing intensifies flavor through Maillard layering by applying dry heat that caramelizes proteins and sugars on meat surfaces, developing complex, savory crusts that brazing's moist, lower-temperature method cannot achieve. This Maillard reaction in barbecuing creates rich, deeply browned flavors and textures essential for artisanal smoked meats, whereas brazing primarily enhances tenderness without substantial flavor crust formation.

Smoke Infusion Profiles

Barbecuing delivers complex smoke infusion profiles by exposing meat to indirect heat and wood smoke over extended periods, enhancing flavor with compounds like guaiacol and syringol. Brazing, primarily a metal-joining technique using high heat and filler metals, lacks the environment needed for smoke infusion and flavorful chemical transformations found in barbecue.

Reverse Sear-Braise Hybrid

The reverse sear-braise hybrid method combines the intense caramelization of barbecuing with the deep flavor infusion of brazing, resulting in a tender, richly flavored meat with a crispy exterior. This technique leverages controlled low-and-slow heat followed by high-temperature searing, maximizing Maillard reactions and collagen breakdown for unparalleled taste complexity.

Fat Rendering Zones

Barbecuing uniquely enhances flavor through controlled fat rendering zones, where slow cooking at low temperatures allows fats to slowly melt, bastes the meat, and develops a rich, smoky taste. In contrast, brazing applies high heat with a molten filler, primarily joining metals without the gradual fat breakdown crucial for flavor intensification in meats.

Micro-Smoke Uptake

Barbecuing enhances flavor through micro-smoke uptake, where slow cooking over wood or charcoal imparts complex smoky compounds that penetrate meat fibers deeply. Brazing, primarily a metal-joining technique, does not contribute to flavor development and lacks the micro-smoke infusion that characterizes traditional barbecue taste profiles.

Glaze Retention Window

Barbecuing enhances flavor by maintaining a glaze retention window during slower, low-temperature cooking, allowing sauces to caramelize without burning. Brazing, typically involving higher heat and liquid immersion, shortens this window, often causing glazes to degrade and lose their rich taste profile.

Wood Essence Braising

Wood essence braising infuses meat with deep, smoky flavors by slowly cooking it in a sealed environment, allowing the wood's aromatic compounds to penetrate the fibers for enhanced taste complexity. Unlike barbecuing, which relies on direct exposure to smoke and heat, braising with wood essence creates tender, juicy results by combining moisture retention with subtle wood-infused aromas.

Crust Optimization

Barbecuing enhances flavor through Maillard reactions that create a rich, caramelized crust known as bark, optimizing taste and texture by combining smoke infusion with high, direct heat. Brazing, while effective for tenderizing, lacks intense surface caramelization, resulting in a less pronounced crust and milder flavor profile.

Sous-Braise Barbecue

Sous-braise barbecue combines slow cooking with precise temperature control to infuse deep flavors and retain moisture, unlike traditional brazing which often lacks the smoky complexity from wood or charcoal. This method enhances meat tenderness while creating rich, layered taste profiles through controlled sous-vide style braising followed by finishing on the grill for that authentic barbecue char.

Barbecuing vs Brazing for Flavor Enhancement Infographic

cookingdiff.com

cookingdiff.com