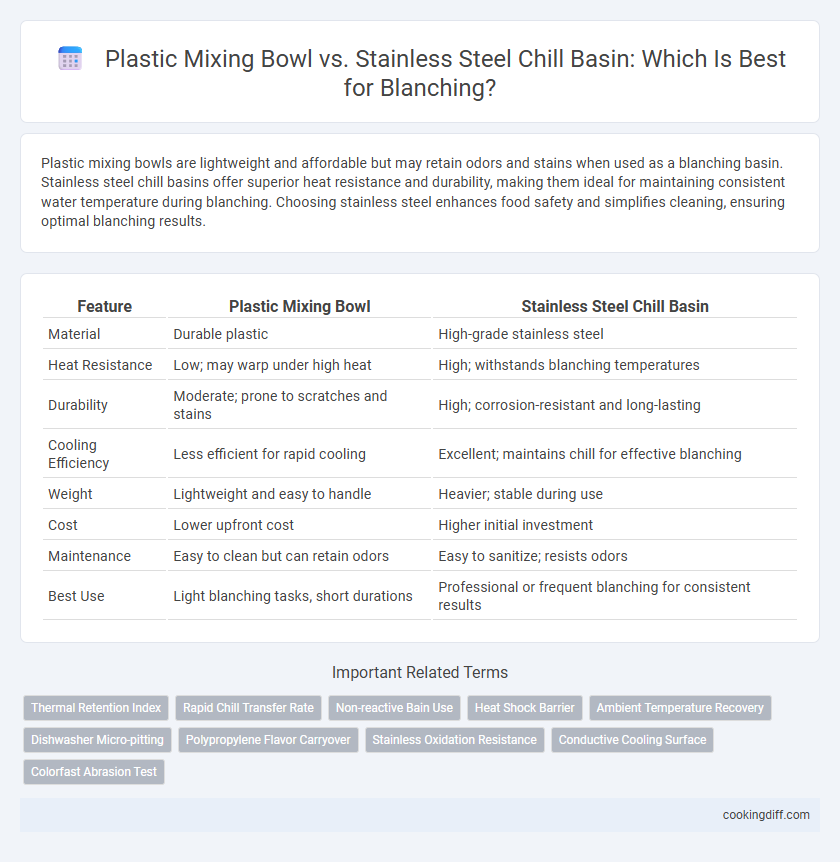

Plastic mixing bowls are lightweight and affordable but may retain odors and stains when used as a blanching basin. Stainless steel chill basins offer superior heat resistance and durability, making them ideal for maintaining consistent water temperature during blanching. Choosing stainless steel enhances food safety and simplifies cleaning, ensuring optimal blanching results.

Table of Comparison

| Feature | Plastic Mixing Bowl | Stainless Steel Chill Basin |

|---|---|---|

| Material | Durable plastic | High-grade stainless steel |

| Heat Resistance | Low; may warp under high heat | High; withstands blanching temperatures |

| Durability | Moderate; prone to scratches and stains | High; corrosion-resistant and long-lasting |

| Cooling Efficiency | Less efficient for rapid cooling | Excellent; maintains chill for effective blanching |

| Weight | Lightweight and easy to handle | Heavier; stable during use |

| Cost | Lower upfront cost | Higher initial investment |

| Maintenance | Easy to clean but can retain odors | Easy to sanitize; resists odors |

| Best Use | Light blanching tasks, short durations | Professional or frequent blanching for consistent results |

Introduction: Importance of Proper Equipment in Blanching

What type of equipment best supports effective blanching for optimal food quality? Proper blanching requires equipment that ensures even heat distribution and durability under high temperatures. Stainless steel chill basins offer superior heat retention and non-reactive surfaces compared to plastic mixing bowls, making them ideal for maintaining food texture and color during the blanching process.

What is Blanching? A Brief Overview

Blanching is a cooking process where vegetables or fruits are briefly boiled in water or steam to halt enzyme actions that cause spoilage. A plastic mixing bowl is lightweight and retains heat, but may not be ideal for quick temperature changes during blanching. Stainless steel chill basins offer superior heat conduction and durability, making them more effective for rapidly cooling or blanching ingredients.

Key Features of Plastic Mixing Bowls

Plastic mixing bowls are lightweight and resistant to corrosion, making them ideal for handling hot water during blanching. They offer flexibility in use while maintaining durability and ease of cleaning compared to stainless steel chill basins.

- Lightweight Material - Plastic mixing bowls are easier to handle and move around during blanching processes.

- Corrosion Resistance - Unlike stainless steel, plastic does not rust or corrode when exposed to hot water.

- Ease of Cleaning - Smooth plastic surfaces prevent food residue buildup and simplify post-blanching cleanup.

Pros and Cons of Plastic Mixing Bowls for Blanching

Plastic mixing bowls are lightweight and less expensive, making them convenient for handling hot vegetables during blanching without causing hand strain. However, they may absorb odors and stains, and their heat resistance is limited compared to metal alternatives, potentially warping under high temperatures.

Plastic bowls are less durable and can scratch easily, harboring bacteria over time, which poses hygiene concerns in repeated blanching tasks. Unlike stainless steel chill basins, they also lack the ability to conduct and retain cold, reducing efficiency in rapidly cooling blanched produce.

Key Features of Stainless Steel Chill Basins

Stainless steel chill basins offer superior thermal conductivity, ensuring rapid cooling after blanching to preserve vegetable texture and color. Their durability and resistance to corrosion make them ideal for repeated use in high-moisture environments.

These chill basins feature a seamless design that prevents bacterial buildup, enhancing food safety standards. Unlike plastic mixing bowls, stainless steel maintains temperature stability, crucial for consistent blanching results. Easy to clean and sanitize, chill basins support efficient kitchen workflows and long-term hygiene.

Pros and Cons of Stainless Steel Chill Basins for Blanching

Stainless steel chill basins offer superior durability and resistance to corrosion, making them ideal for repeated blanching processes. Their non-reactive surface prevents any metallic taste transfer, preserving food quality.

- Durability - Stainless steel basins withstand high temperatures and frequent use without warping or cracking.

- Hygiene - The smooth, non-porous surface resists bacterial growth and is easy to sanitize.

- Heat retention - Stainless steel efficiently maintains cold temperatures, ensuring effective blanching.

The initial higher cost of stainless steel chill basins is offset by their long-term reliability and food safety benefits.

Heat Retention and Temperature Control Comparison

Stainless steel chill basins provide superior heat retention and maintain a more stable temperature during blanching compared to plastic mixing bowls. Plastic bowls tend to cool down quickly, requiring more frequent reheating to sustain the blanching process.

- Heat Retention - Stainless steel's higher thermal conductivity ensures consistent heat, improving blanching efficiency.

- Temperature Stability - Stainless steel chill basins keep water temperature steady, preventing undercooking.

- Plastic Limitations - Plastic mixing bowls lose heat faster, making precise temperature control challenging.

Durability and Longevity: Which Material Lasts Longer?

Stainless steel chill basins offer superior durability for blanching due to their resistance to corrosion, heat, and impact, making them ideal for long-term use. Plastic mixing bowls, while lightweight and affordable, tend to degrade over time when exposed to high temperatures and frequent washing.

In terms of longevity, stainless steel maintains structural integrity and appearance despite repeated blanching cycles, ensuring consistent performance. Plastic bowls may crack or warp, reducing their lifespan and reliability for sustained kitchen use.

Safety and Food Hygiene Considerations

| Material | Safety | Food Hygiene |

|---|---|---|

| Plastic Mixing Bowl | Risk of scratching and melting when exposed to high blanching temperatures, potentially releasing harmful chemicals. | More prone to retaining odors and stains, increasing the risk of bacterial growth if not cleaned thoroughly. |

| Stainless Steel Chill Basin | Highly resistant to heat and physical damage, ensuring no chemical leaching during blanching processes. | Non-porous surface minimizes bacterial buildup, allowing for easier sanitation and compliance with food safety standards. |

Related Important Terms

Thermal Retention Index

Stainless steel chill basins offer a higher Thermal Retention Index compared to plastic mixing bowls, ensuring more efficient temperature maintenance during blanching. This superior thermal conductivity in stainless steel accelerates the cooling process, preserving vegetable texture and nutrient content more effectively.

Rapid Chill Transfer Rate

Stainless steel chill basins offer a significantly faster chill transfer rate compared to plastic mixing bowls, allowing blanched vegetables to cool rapidly and preserve texture and color. The high thermal conductivity of stainless steel ensures efficient heat dissipation, preventing overcooking and enhancing food safety during blanching processes.

Non-reactive Bain Use

Stainless steel chill basins are preferred for blanching due to their non-reactive properties, preventing any chemical reactions with hot water or food acids, which can occur with some plastic mixing bowls. The durability and heat resistance of stainless steel ensure safer, more hygienic blanching, avoiding potential contamination and maintaining food quality.

Heat Shock Barrier

Plastic mixing bowls provide a superior heat shock barrier compared to stainless steel chill basins, minimizing the risk of temperature-induced cracking during blanching. Their insulating properties help maintain consistent heat transfer, ensuring even blanching without sudden temperature fluctuations.

Ambient Temperature Recovery

Plastic mixing bowls provide better ambient temperature recovery during blanching due to their insulating properties, which help maintain a consistent water temperature between batches. In contrast, stainless steel chill basins rapidly dissipate heat, causing more frequent temperature drops that can extend blanching times and reduce overall efficiency.

Dishwasher Micro-pitting

Plastic mixing bowls resist dishwasher micro-pitting, maintaining a smooth surface ideal for blanching applications, while stainless steel chill basins often develop micro-pitting from repeated dishwasher exposure, which can harbor bacteria and degrade performance. Choosing plastic reduces long-term maintenance issues related to corrosion and surface integrity during high-temperature blanching processes.

Polypropylene Flavor Carryover

Polypropylene plastic mixing bowls are preferred for blanching due to their low flavor carryover, minimizing contamination between different batches, whereas stainless steel chill basins may retain odor and flavor residues despite thorough cleaning. The non-porous surface of polypropylene resists absorption of oils and aromas, ensuring optimal preservation of food flavors during repeated blanching processes.

Stainless Oxidation Resistance

Stainless steel chill basins offer superior oxidation resistance compared to plastic mixing bowls, preventing corrosion and maintaining food safety during blanching processes. Their durable, non-reactive surface ensures consistent temperature control and longevity, making them ideal for high-heat applications in blanching.

Conductive Cooling Surface

Stainless steel chill basins provide superior conductive cooling surfaces compared to plastic mixing bowls, enabling faster and more even heat transfer during blanching. This enhanced conductivity reduces cooling time, preserving vegetable texture and color more effectively.

Plastic Mixing Bowl vs Stainless Steel Chill Basin for blanching. Infographic

cookingdiff.com

cookingdiff.com