Copper pots excel in boiling due to their superior thermal conductivity, allowing rapid and even heat distribution, which reduces cooking time and prevents hotspots. Ceramic induction pots offer the advantage of non-reactive surfaces, ensuring no metallic taste is imparted to the boiled water, and they retain heat longer due to their insulating properties. Choosing between the two depends on whether speed and precise temperature control or material safety and heat retention are prioritized for boiling tasks.

Table of Comparison

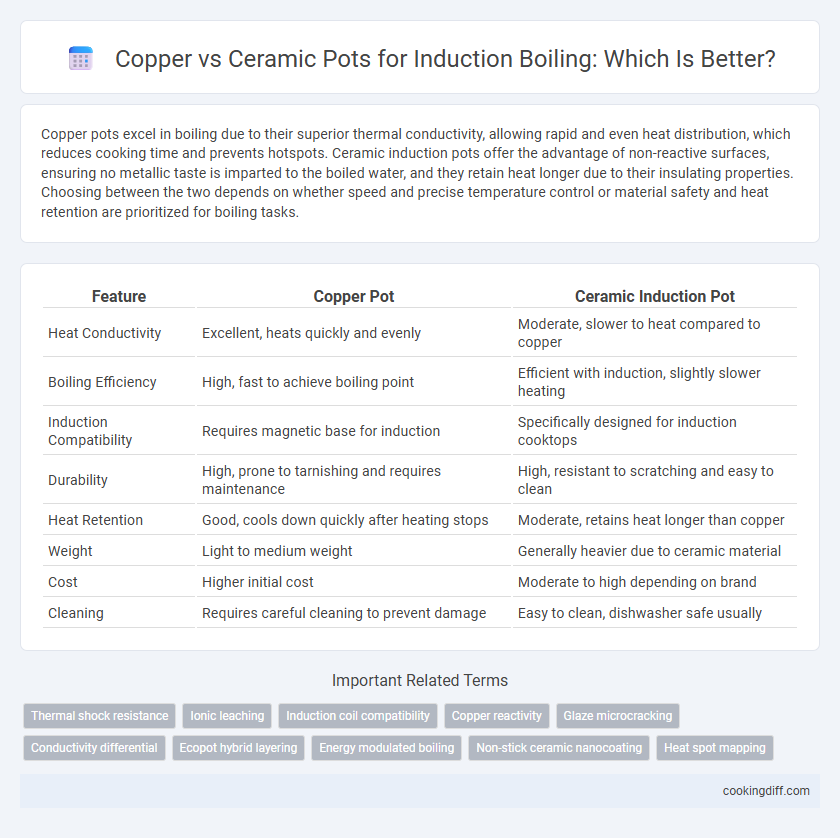

| Feature | Copper Pot | Ceramic Induction Pot |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, slower to heat compared to copper |

| Boiling Efficiency | High, fast to achieve boiling point | Efficient with induction, slightly slower heating |

| Induction Compatibility | Requires magnetic base for induction | Specifically designed for induction cooktops |

| Durability | High, prone to tarnishing and requires maintenance | High, resistant to scratching and easy to clean |

| Heat Retention | Good, cools down quickly after heating stops | Moderate, retains heat longer than copper |

| Weight | Light to medium weight | Generally heavier due to ceramic material |

| Cost | Higher initial cost | Moderate to high depending on brand |

| Cleaning | Requires careful cleaning to prevent damage | Easy to clean, dishwasher safe usually |

Introduction: Copper vs Ceramic Induction Pots for Boiling

Copper pots offer rapid and even heat distribution, making them ideal for precise boiling control. Ceramic induction pots, designed for induction cooktops, provide excellent heat retention and energy efficiency.

Copper's superior thermal conductivity allows water to reach boiling point quickly and maintain consistent temperature, reducing cooking time. Ceramic induction pots heat more gradually but retain heat longer, minimizing energy consumption during boiling. Choosing between copper and ceramic induction pots depends on your cooking style and the compatibility with your stove.

Heat Conductivity: Copper Versus Ceramic Induction

Copper pots offer superior heat conductivity compared to ceramic induction pots, allowing for faster and more even boiling. Ceramic induction pots, while slower to heat, maintain stable temperatures and prevent hotspots during boiling.

- Copper's Thermal Conductivity - Copper has a thermal conductivity of approximately 400 W/m*K, enabling rapid heat transfer and quick boiling times.

- Ceramic Induction Heat Distribution - Ceramic pots heat through induction-compatible bases but have lower thermal conductivity, around 1.5 W/m*K, leading to slower heat spread.

- Boiling Efficiency - Copper pots reach boiling temperatures faster, whereas ceramic induction pots offer consistent heat retention, reducing temperature fluctuations during boiling.

Boiling Speed Comparison: Which Pot Wins?

Copper pots excel in boiling speed due to their superior thermal conductivity of approximately 401 W/mK, allowing rapid and even heat distribution. Ceramic induction pots, while compatible with induction cooktops, have lower thermal conductivity, resulting in slower boiling times. For efficient boiling performance, copper pots distinctly outperform ceramic induction pots in speed and heat responsiveness.

Energy Efficiency in Boiling: Copper or Ceramic Induction?

Copper pots excel in energy efficiency due to their superior thermal conductivity, allowing rapid and even heat distribution that reduces boiling time and energy consumption. Their ability to quickly adjust to temperature changes minimizes heat loss during heating.

Ceramic induction pots, compatible with induction cooktops, offer energy savings by directly transferring electromagnetic energy to the pot, resulting in faster boiling and less wasted heat compared to traditional cooking methods. However, ceramic materials have lower thermal conductivity than copper, which may slightly increase boiling duration despite induction efficiency.

Durability and Longevity: Copper vs Ceramic Induction Pots

Copper pots exhibit exceptional durability due to their robust metal composition that resists warping and corrosion over time. Ceramic induction pots offer good longevity but are more prone to chipping and cracking under thermal stress or accidental drops.

- Copper's Strength - Copper is highly resistant to physical damage and maintains structural integrity after prolonged use.

- Ceramic Fragility - Ceramic coatings can degrade or chip, reducing pot lifespan with improper handling.

- Heat Resistance - Copper evenly distributes heat, minimizing hot spots that can weaken material faster compared to ceramic.

Choosing copper enhances long-term investment through superior durability in boiling applications compared to ceramic induction pots.

Safety Factors While Boiling: Material Considerations

Copper pots offer excellent thermal conductivity, allowing rapid and even heating, but require careful handling due to their reactive nature with acidic foods, which may pose health risks. Ceramic induction pots provide a non-reactive, smooth surface that prevents leaching of metals into food, enhancing safety during boiling.

While copper cookware often needs seasoning or lining to avoid metal exposure, ceramic pots avoid this issue, reducing maintenance concerns. The inert composition of ceramic induction pots minimizes the risk of chemical contamination, making them a safer choice for boiling processes where material integrity is critical.

Maintenance and Cleaning: Copper vs Ceramic Induction

Which material requires less maintenance for boiling, copper or ceramic induction pots? Copper pots demand regular polishing to prevent tarnish and maintain their heat conductivity, while ceramic induction pots feature non-stick surfaces that simplify cleaning. Ceramic pots generally resist staining and corrosion better, reducing long-term upkeep efforts compared to copper cookware.

Flavor and Food Reaction: Pot Material Impact on Boiling

| Flavor Retention | Copper pots offer excellent heat conductivity, ensuring even boiling and preservation of natural food flavors without metallic aftertaste. |

| Ceramic Induction Compatibility | Ceramic induction pots provide a non-reactive surface that prevents chemical reactions during boiling, maintaining pure taste but may heat less evenly than copper. |

| Food Reaction | Copper can sometimes react with acidic ingredients, subtly altering flavor, while ceramic materials resist such reactions, preserving original food qualities during boiling. |

Compatibility with Cooktops: Copper Versus Ceramic Induction

Copper pots are generally incompatible with induction cooktops due to their non-magnetic properties, whereas ceramic induction pots are specifically designed for optimal induction cooking performance. The magnetic base of ceramic pots allows for efficient heat transfer and precise temperature control on induction surfaces.

- Copper's Non-Magnetic Limitation - Copper pots cannot activate induction cooktops as they lack the ferromagnetic base needed for electromagnetic heating.

- Ceramic Induction Compatibility - Ceramic induction pots feature a magnetic base layer that ensures they work seamlessly with induction cooktops.

- Heat Precision - Ceramic induction pots provide consistent heat distribution and rapid boiling on induction stoves, unlike copper pots without added magnetic layers.

Related Important Terms

Thermal shock resistance

Copper pots excel in thermal conductivity, allowing rapid and even heating, but they are more susceptible to thermal shock due to rapid temperature changes which can cause warping or damage. Ceramic induction pots offer superior thermal shock resistance with gradual heat distribution, minimizing the risk of cracking or breakage during sudden temperature shifts, making them ideal for consistent boiling processes.

Ionic leaching

Copper pots, known for excellent thermal conductivity, may release trace amounts of copper ions into boiling water, potentially causing ionic leaching concerns with prolonged use. Ceramic induction pots offer a non-reactive surface that minimizes ionic leaching, preserving water purity while providing efficient heat distribution on induction cooktops.

Induction coil compatibility

Copper pots exhibit limited compatibility with induction coils due to their non-ferromagnetic properties, resulting in inefficient or absent heating on induction cooktops. Ceramic induction pots, designed with ferromagnetic bases, provide optimal magnetic field interaction, ensuring rapid and uniform boiling performance with induction coils.

Copper reactivity

Copper pots offer superior thermal conductivity for faster boiling but react with acidic foods, potentially causing metallic taste and health concerns, whereas ceramic induction pots provide non-reactive, safe cooking surfaces ideal for boiling a variety of liquids without flavor alteration. The interaction of copper with acidic substances necessitates frequent seasoning or lining to prevent reactivity, unlike the inert ceramic material that maintains purity during the boiling process.

Glaze microcracking

Copper pots offer superior heat conductivity for rapid boiling but risk uneven heating that can exacerbate glaze microcracking in ceramic induction pots. Ceramic induction pots feature durable, heat-resistant glazes designed to minimize microcracking despite slower, more controlled boiling temperatures.

Conductivity differential

Copper pots offer superior thermal conductivity at approximately 400 W/m*K, enabling rapid and even boiling, while ceramic induction pots have lower conductivity around 1.5 W/m*K, resulting in slower heat transfer and less uniform temperature distribution. This conductivity differential significantly affects boiling efficiency, with copper vessels facilitating faster heat-up times and precise temperature control compared to ceramic induction cookware.

Ecopot hybrid layering

Ecopot hybrid layering in ceramic induction pots enhances heat distribution and energy efficiency, offering faster and more uniform boiling compared to traditional copper pots. Copper pots, while excellent for heat conductivity, lack the advanced multi-layer technology that optimizes temperature control in induction cooking.

Energy modulated boiling

Copper pots provide superior energy modulation during boiling due to their high thermal conductivity of approximately 401 W/m*K, enabling rapid and precise temperature adjustments. Ceramic induction pots, while compatible with induction cooktops, have lower thermal conductivity, around 20-30 W/m*K, resulting in slower heat response and less efficient energy transfer for boiling tasks.

Non-stick ceramic nanocoating

Copper pots provide rapid and even heat distribution ideal for boiling, but ceramic induction pots with non-stick ceramic nanocoating prevent food from sticking while ensuring efficient heat conductivity on induction stoves. The nanocoating enhances durability and ease of cleaning, making ceramic induction pots a practical choice for boiling with minimal residue and energy use.

Copper pot vs Ceramic induction pot for boiling. Infographic

cookingdiff.com

cookingdiff.com