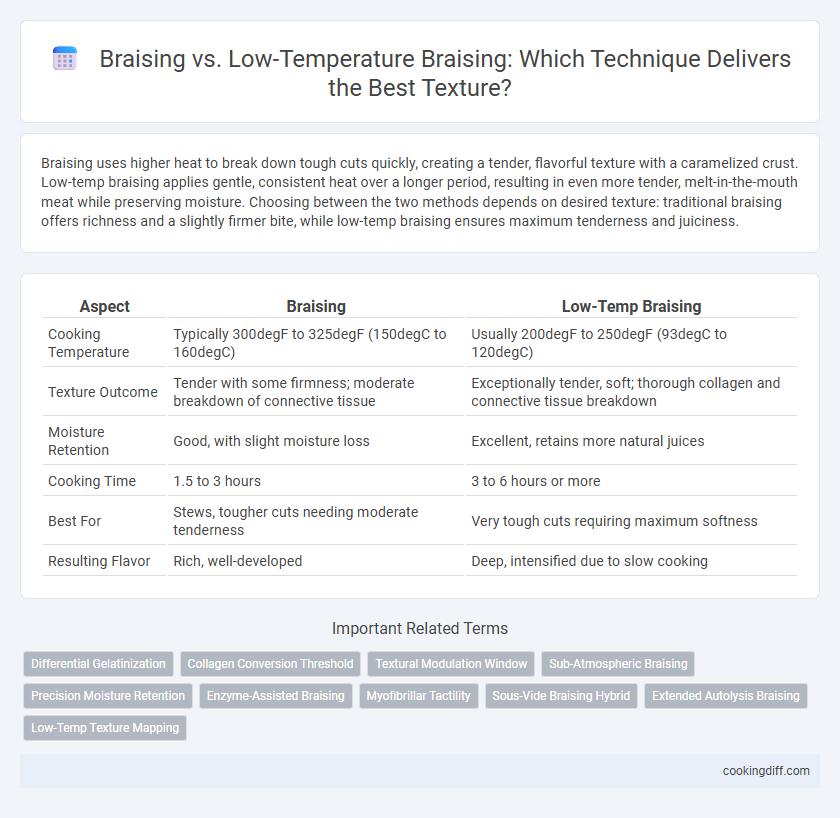

Braising uses higher heat to break down tough cuts quickly, creating a tender, flavorful texture with a caramelized crust. Low-temp braising applies gentle, consistent heat over a longer period, resulting in even more tender, melt-in-the-mouth meat while preserving moisture. Choosing between the two methods depends on desired texture: traditional braising offers richness and a slightly firmer bite, while low-temp braising ensures maximum tenderness and juiciness.

Table of Comparison

| Aspect | Braising | Low-Temp Braising |

|---|---|---|

| Cooking Temperature | Typically 300degF to 325degF (150degC to 160degC) | Usually 200degF to 250degF (93degC to 120degC) |

| Texture Outcome | Tender with some firmness; moderate breakdown of connective tissue | Exceptionally tender, soft; thorough collagen and connective tissue breakdown |

| Moisture Retention | Good, with slight moisture loss | Excellent, retains more natural juices |

| Cooking Time | 1.5 to 3 hours | 3 to 6 hours or more |

| Best For | Stews, tougher cuts needing moderate tenderness | Very tough cuts requiring maximum softness |

| Resulting Flavor | Rich, well-developed | Deep, intensified due to slow cooking |

Understanding Braising: Classic Techniques

Braising combines searing and slow cooking in liquid to tenderize tough cuts of meat through collagen breakdown. Low-temperature braising maintains a stable heat, producing a more uniform texture and preserving moisture better than traditional higher-heat methods.

- Classic Braising Technique - Involves initial high-heat searing followed by slow cooking at moderate temperatures to develop deep flavors and tenderize fibers.

- Low-Temperature Braising - Utilizes gentle heat below 160degF (71degC) for extended periods to minimize muscle fiber contraction and retain juiciness.

- Texture Impact - Lower temperatures yield softer, more consistent textures while avoiding toughness often caused by excessive heat during braising.

What is Low-Temperature Braising?

Low-temperature braising is a cooking technique that involves simmering meat or vegetables at a temperature typically between 160degF and 180degF, resulting in tender, evenly cooked textures. This method contrasts with traditional braising, which uses higher heat and often leads to faster cooking but less control over texture.

- Gentle Heat - Maintains a steady, low temperature that prevents overcooking and preserves moisture.

- Longer Cooking Time - Requires extended cooking periods, allowing tougher fibers to break down gradually.

- Enhanced Tenderness - Produces a more uniformly tender and juicy texture compared to high-temperature braising.

Low-temperature braising is ideal for achieving precise texture control in slow-cooked dishes.

Key Differences Between Traditional and Low-Temp Braising

Traditional braising involves cooking meat at higher temperatures, typically between 300degF and 350degF, resulting in a quicker breakdown of collagen and a firmer texture. Low-temp braising, at temperatures around 190degF to 225degF, promotes a gentler collagen conversion, producing a more tender and evenly cooked texture.

Key differences lie in the cooking time and temperature control; traditional braising cooks faster but may yield slightly firmer meat, while low-temp braising requires longer cooking durations to achieve melt-in-the-mouth tenderness. Low-temp braising also helps retain moisture better and prevents overcooking. This method is ideal for tougher cuts, enhancing texture through slow, controlled heat.

Texture Outcomes: Braising vs Low-Temp Braising

Braising uses moderate heat to break down collagen in meats, resulting in a tender texture with a slight firmness. Low-temperature braising, maintained around 160-180degF (71-82degC), allows collagen to dissolve slowly, producing a more consistently soft and silky texture.

Traditional braising can sometimes lead to uneven texture due to higher heat gradients, while low-temp braising ensures uniform doneness throughout the meat. This slower process preserves moisture better, enhancing juiciness and mouthfeel in tougher cuts.

Meat Tenderness: Which Method Wins?

Braising involves cooking meat slowly in liquid at medium heat, breaking down collagen for a tender texture, while low-temp braising uses a lower heat over a longer time to achieve even more consistent tenderness. Meat fibers retain moisture better in low-temp braising, resulting in a juicier and more succulent bite compared to traditional braising.

While traditional braising can produce tender meat relatively quickly, low-temp braising excels at preserving the meat's natural juices and creating a melt-in-your-mouth texture. Studies show that meat cooked at lower temperatures between 160-180degF for extended periods is less likely to toughen, making low-temp braising the preferred method for maximum tenderness.

Moisture Retention: How Each Technique Performs

| Technique | Moisture Retention | Texture Outcome |

|---|---|---|

| Braising | Moderate moisture retention due to higher temperatures causing some evaporation | Produces tender meat with a slightly firmer texture |

| Low-Temp Braising | Superior moisture retention by cooking at lower temperatures and reducing evaporation | Yields exceptionally juicy and tender meat with a delicate, melt-in-the-mouth texture |

Flavor Development: Comparing Methods

Braising at higher temperatures accelerates Maillard reactions, producing a deeper, more robust flavor profile, while low-temp braising enhances subtle, complex flavors through prolonged cooking. Flavor development is influenced by temperature control and cooking duration, affecting the intensity and harmony of taste components.

- Higher-Temperature Braising - Promotes rapid Maillard browning, intensifying savory and caramelized notes.

- Low-Temperature Braising - Facilitates gradual flavor extraction and amalgamation without overt caramelization.

- Flavor Complexity - Longer low-temp cooking produces nuanced and layered taste profiles compared to shorter high-temp methods.

Ideal Cuts for Each Braising Approach

Which cuts of meat are best suited for braising compared to low-temp braising? Traditional braising works well with tougher, collagen-rich cuts like beef chuck or pork shoulder, which break down and become tender through high heat and moisture. Low-temp braising favors more delicate cuts such as short ribs or lamb shanks, preserving their texture while slowly rendering connective tissues over extended cooking times.

Time and Temperature Considerations

Braising typically involves cooking meat at temperatures around 300degF (150degC) for 2 to 3 hours, allowing tough cuts to break down evenly while preserving moisture. Low-temp braising uses temperatures closer to 200degF (93degC) and extends cooking time to 4 to 6 hours, resulting in a more tender, melt-in-the-mouth texture. The balance between time and temperature directly impacts collagen breakdown and moisture retention, influencing the final dish's texture and juiciness.

Related Important Terms

Differential Gelatinization

Braising at higher temperatures rapidly breaks down collagen into gelatin, creating a tender texture with some moisture loss, while low-temp braising allows for controlled, gradual gelatinization that preserves more juiciness and yields a silkier mouthfeel. Differential gelatinization during low-temp braising enhances collagen conversion efficiency, optimizing texture by balancing tenderness and moisture retention.

Collagen Conversion Threshold

Braising requires maintaining temperatures between 160degF and 180degF to effectively convert collagen into gelatin, enhancing meat tenderness and moisture retention. Low-temp braising, performed just above the collagen conversion threshold (around 160degF), allows for gradual collagen breakdown, resulting in a more succulent and evenly textured dish.

Textural Modulation Window

Braising achieves tender textures by cooking meat at moderate heat with moisture over extended time, while low-temp braising expands the textural modulation window by gently breaking down collagen without overcooking muscle fibers. This method allows precise control over tenderness and juiciness, optimizing the mouthfeel and structural integrity of the final dish.

Sub-Atmospheric Braising

Sub-atmospheric braising enhances texture by cooking food in a vacuum-sealed environment at low temperatures, resulting in superior moisture retention and tenderizing effects compared to traditional braising methods. This technique minimizes oxidation and evaporation, preserving the food's natural flavors and creating a consistently delicate, melt-in-the-mouth texture.

Precision Moisture Retention

Braising uses moderate heat and liquid to break down collagen, while low-temp braising employs precise temperature control to enhance moisture retention, resulting in a more tender and juicy texture. Low-temp braising minimizes evaporation and overcooking, preserving the meat's natural succulence more effectively than traditional methods.

Enzyme-Assisted Braising

Enzyme-assisted braising enhances meat tenderness by activating natural proteolytic enzymes at controlled low temperatures, breaking down collagen more effectively than traditional braising methods. This technique maintains optimal moisture retention while achieving a uniformly soft texture, ideal for tougher cuts requiring extended cooking times.

Myofibrillar Tactility

Braising develops myofibrillar tactility by breaking down collagen slowly, resulting in tender yet structured meat fibers, while low-temp braising preserves more of the muscle's inherent texture by minimizing fiber contraction. The precise temperature control in low-temp braising enhances moisture retention and yields a more consistent, delicate mouthfeel compared to traditional braising methods.

Sous-Vide Braising Hybrid

Sous-vide braising hybrid combines precise temperature control of sous-vide with traditional braising's moisture retention, resulting in exceptionally tender and uniformly cooked textures. This method minimizes overcooking and enhances collagen breakdown, producing consistently succulent meats compared to conventional low-temperature braising.

Extended Autolysis Braising

Extended autolysis braising enhances meat tenderness by allowing enzymes to break down connective tissues at moderate temperatures over prolonged periods, resulting in a more velvety texture compared to traditional low-temp braising. This method optimizes collagen conversion into gelatin, producing a juicier, melt-in-the-mouth consistency without the dryness often associated with high-heat cooking.

Braising vs Low-Temp Braising for Texture. Infographic

cookingdiff.com

cookingdiff.com