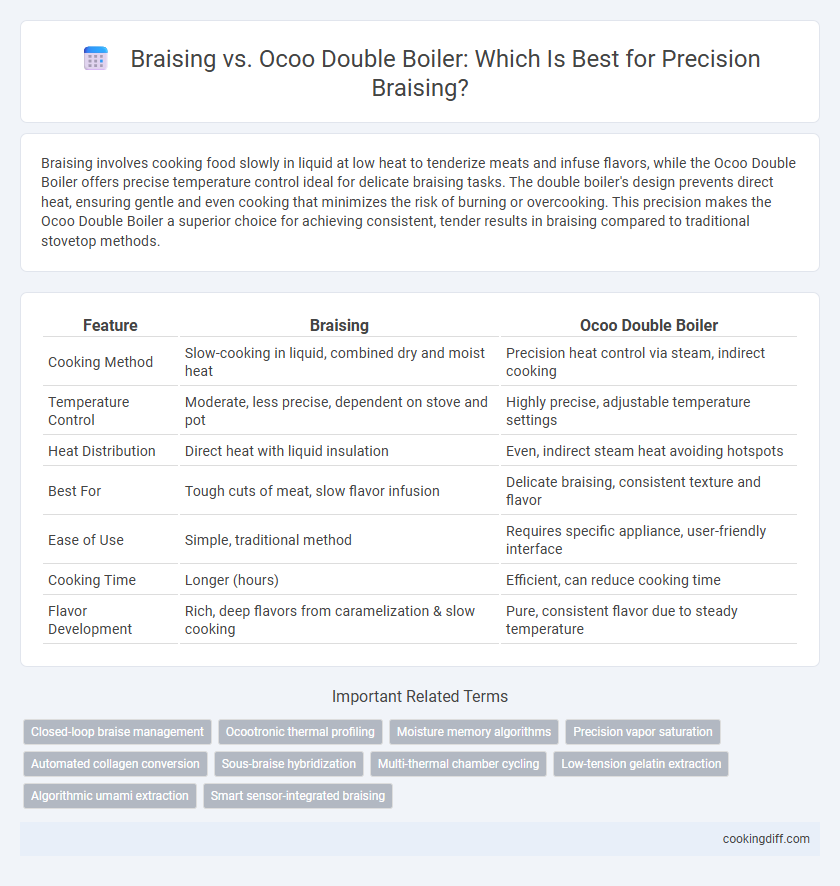

Braising involves cooking food slowly in liquid at low heat to tenderize meats and infuse flavors, while the Ocoo Double Boiler offers precise temperature control ideal for delicate braising tasks. The double boiler's design prevents direct heat, ensuring gentle and even cooking that minimizes the risk of burning or overcooking. This precision makes the Ocoo Double Boiler a superior choice for achieving consistent, tender results in braising compared to traditional stovetop methods.

Table of Comparison

| Feature | Braising | Ocoo Double Boiler |

|---|---|---|

| Cooking Method | Slow-cooking in liquid, combined dry and moist heat | Precision heat control via steam, indirect cooking |

| Temperature Control | Moderate, less precise, dependent on stove and pot | Highly precise, adjustable temperature settings |

| Heat Distribution | Direct heat with liquid insulation | Even, indirect steam heat avoiding hotspots |

| Best For | Tough cuts of meat, slow flavor infusion | Delicate braising, consistent texture and flavor |

| Ease of Use | Simple, traditional method | Requires specific appliance, user-friendly interface |

| Cooking Time | Longer (hours) | Efficient, can reduce cooking time |

| Flavor Development | Rich, deep flavors from caramelization & slow cooking | Pure, consistent flavor due to steady temperature |

Understanding the Basics: Traditional Braising vs. Ocoo Double Boiler

Traditional braising involves slow-cooking food in a covered pot with a small amount of liquid, allowing the heat to penetrate evenly and break down tough fibers for tender results. The Ocoo Double Boiler enhances precision braising by using a controlled water bath to maintain consistent, low temperatures, preventing overcooking and preserving moisture.

Unlike conventional methods where heat distribution can vary, the Ocoo Double Boiler ensures stable temperature management ideal for delicate cuts and delicate flavors. This modern approach merges gentle heat application with the deep flavor development of traditional braising, offering superior texture and taste control.

Precision Temperature Control: Comparing Techniques

Braising relies on slow cooking at low, steady heat to break down tough fibers for tender results, whereas the Ocoo double boiler offers precise temperature control by maintaining consistent gentle heat. This precision temperature control minimizes the risk of overcooking or drying out ingredients, ideal for delicate braising tasks.

- Braising Temperature Range - Typically involves cooking between 160degF to 300degF to slowly tenderize tougher cuts of meat.

- Ocoo Double Boiler Precision - Maintains exact temperatures usually within +-1degF, ensuring even and controlled heat distribution.

- Heat Management - Braising requires careful monitoring to avoid temperature fluctuations that the Ocoo double boiler inherently prevents through its design.

Flavor Development: Which Method Enhances Taste?

| Flavor Development in Braising vs Ocoo Double Boiler |

| Braising enhances taste through direct contact with both dry and moist heat, promoting caramelization and Maillard reactions that deepen flavor complexity. Ocoo Double Boiler provides gentle, even heat ideal for slow infusion of flavors but lacks the high-temperature searing crucial for rich, robust taste development. Precision braising utilizing traditional pots ensures intensified flavor by balancing temperature gradients, unlike the Ocoo method which prioritizes temperature control over flavor layering. |

Moisture Retention: Ocoo Double Boiler vs. Classic Braising

How does moisture retention compare between the Ocoo Double Boiler and classic braising methods? The Ocoo Double Boiler uses indirect, gentle heat to maintain consistent moisture, preventing drying out of ingredients. Classic braising combines searing and slow cooking in liquid, but often results in some evaporation and moisture loss during cooking.

Texture Outcomes: Achieving Tenderness Every Time

Braising offers deep, rich flavor development through slow cooking, but achieving consistent tenderness can be challenging without precise temperature control. The Ocoo double boiler provides a regulated, gentle heat source that ensures even cooking, resulting in uniformly tender textures every time.

- Consistent Heat Distribution - Ocoo double boiler maintains steady temperatures to prevent overcooking or drying out meat.

- Enhanced Moisture Retention - Braising in the double boiler locks in juices, preserving tenderness and succulence.

- Precision Temperature Control - Ensures optimal collagen breakdown, transforming tough cuts into melt-in-your-mouth dishes.

Using an Ocoo double boiler refines traditional braising by delivering reliable texture outcomes with minimal effort.

Time Efficiency: Braising vs. Ocoo Double Boiler Performance

Braising typically requires longer cooking times due to direct heat application, which can lead to uneven temperature control. The Ocoo Double Boiler offers precise temperature regulation that reduces cooking time while preserving moisture and texture in the ingredients.

Ocoo Double Boiler's controlled heating minimizes the risk of overcooking, enhancing time efficiency without sacrificing flavor. In contrast, traditional braising demands closer monitoring and adjustments to avoid prolonged cooking durations.

Nutrient Preservation: Does Ocoo Have the Advantage?

Braising typically involves cooking food slowly in a covered pot with a small amount of liquid, which can sometimes lead to nutrient loss due to prolonged exposure to heat. The Ocoo Double Boiler provides a more precise temperature control by using indirect steam heat, which better preserves heat-sensitive vitamins and minerals. This method reduces nutrient degradation, giving Ocoo a clear advantage in maintaining the nutritional value during the braising process.

Versatility in the Kitchen: Use Cases for Both Methods

Braising offers versatility by allowing slow cooking in a single pot, ideal for tough cuts of meat and vegetables that require tenderizing and flavor infusion. The Ocoo Double Boiler enhances precision braising by providing controlled, indirect heat, which prevents scorching and allows delicate dishes like custards or fish to cook evenly. Both methods complement each other in the kitchen, with braising excelling in depth of flavor and the double boiler excelling in temperature control for delicate ingredients.

Energy Consumption and Cost Considerations

Braising in a traditional black pot often consumes more energy due to longer cooking times and less efficient heat distribution compared to the Ocoo Double Boiler, which uses a water bath to maintain precise temperature control and reduce energy waste. The Ocoo Double Boiler's energy-efficient design results in lower electricity costs over extended cooking periods.

The Ocoo Double Boiler minimizes heat loss by circulating hot water evenly, allowing for consistent low-temperature cooking ideal for delicate braises. This precise temperature control reduces overcooking risks and saves energy by preventing heat spikes common with direct heat methods. While initial investment in an Ocoo Double Boiler may be higher, long-term savings in energy bills and improved food quality justify the cost for serious cooks focusing on precision braising.

Related Important Terms

Closed-loop braise management

Closed-loop braise management in braising offers precise temperature control by continuously monitoring and adjusting heat to maintain optimal moisture and flavor extraction, essential for tenderizing tough cuts. While traditional Ocoo double boilers provide gentle heat, advanced closed-loop systems enhance consistency and reduce overcooking risks by automating temperature regulation throughout the braising process.

Ocootronic thermal profiling

Ocoo Double Boiler utilizes advanced Ocootronic thermal profiling to maintain precise, consistent temperatures ideal for braising, reducing the risk of overcooking or uneven heat distribution common in traditional braising methods. This precise thermal control enhances flavor development and texture by gently cooking ingredients in a controlled moist heat environment.

Moisture memory algorithms

Braising with a Ocoo double boiler leverages advanced moisture memory algorithms to maintain precise temperature and optimal humidity levels, enhancing meat tenderness and flavor retention. This technology contrasts traditional braising by enabling consistent, controlled moisture recycling, which prevents drying out and ensures evenly cooked, succulent results.

Precision vapor saturation

Braising with an Ocoo Double Boiler ensures precision vapor saturation by maintaining consistent, controlled heat and moisture levels, crucial for tenderizing tougher cuts of meat without drying them out. Unlike traditional braising methods, the Ocoo Double Boiler's sealed environment prevents flavor loss and optimizes heat distribution, resulting in evenly cooked, flavorful dishes.

Automated collagen conversion

Braising with an Ocoo Double Boiler offers unparalleled precision in automated collagen conversion by maintaining consistent low temperatures, ensuring tender, juicy results without overcooking. This method surpasses traditional braising techniques by using controlled heat and steam circulation to enhance collagen breakdown, optimizing flavor and texture in slow-cooked dishes.

Sous-braise hybridization

Braising combined with Ocoo Double Boiler technology enhances precision braising by maintaining consistent low temperatures and moisture control, essential for tenderizing tough cuts. The sous-braise hybridization optimizes heat distribution and flavor infusion, surpassing traditional methods in texture and taste refinement.

Multi-thermal chamber cycling

Braising with a multi-thermal chamber cycling system, such as the Ocoo Double Boiler, ensures precise temperature control by alternating heat between chambers for even cooking and moisture retention. This method prevents overcooking and preserves texture compared to traditional braising techniques, optimizing flavor development through stable, controlled heat environments.

Low-tension gelatin extraction

Braising excels in low-tension gelatin extraction by gently cooking collagen-rich cuts at consistent low temperatures, resulting in tender, flavorful dishes with natural gelatin release. Compared to the Ocoo Double Boiler, traditional braising offers more precise control over heat application, minimizing the risk of overcooking and preserving the delicate gelatin structure essential for optimal texture.

Algorithmic umami extraction

Braising with an Ocoo double boiler enhances algorithmic umami extraction by maintaining consistent low temperatures and precise moisture control, intensifying savory flavors without overcooking. Traditional braising methods lack this precise thermal regulation, often resulting in uneven flavor development and less optimal umami concentration.

Braising vs Ocoo Double Boiler for precision braising. Infographic

cookingdiff.com

cookingdiff.com