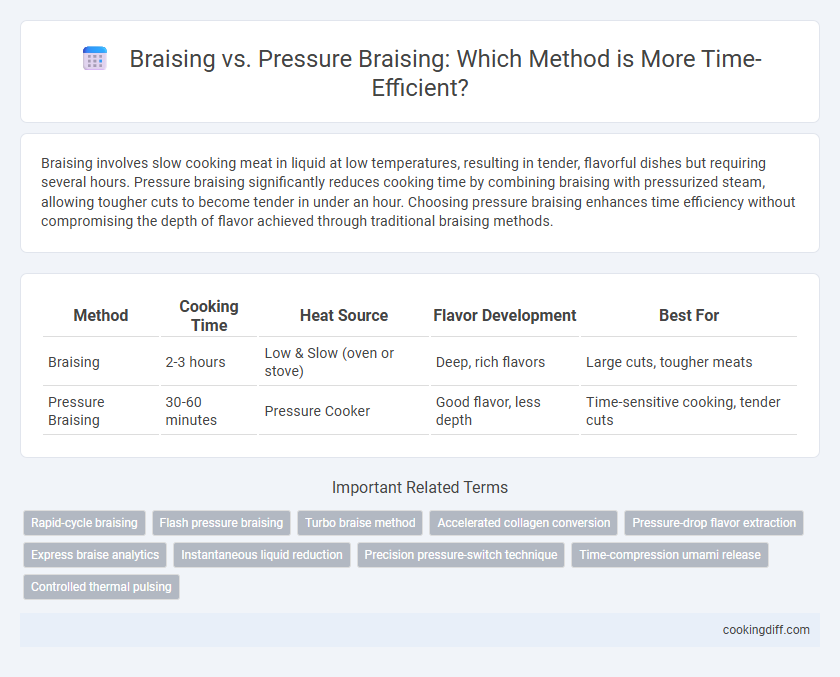

Braising involves slow cooking meat in liquid at low temperatures, resulting in tender, flavorful dishes but requiring several hours. Pressure braising significantly reduces cooking time by combining braising with pressurized steam, allowing tougher cuts to become tender in under an hour. Choosing pressure braising enhances time efficiency without compromising the depth of flavor achieved through traditional braising methods.

Table of Comparison

| Method | Cooking Time | Heat Source | Flavor Development | Best For |

|---|---|---|---|---|

| Braising | 2-3 hours | Low & Slow (oven or stove) | Deep, rich flavors | Large cuts, tougher meats |

| Pressure Braising | 30-60 minutes | Pressure Cooker | Good flavor, less depth | Time-sensitive cooking, tender cuts |

Understanding Braising: Traditional Cooking Method

Braising is a slow-cooking method that uses low heat and moisture to tenderize tougher cuts of meat over several hours. Pressure braising speeds up this process by using high pressure to increase the boiling point of liquid, significantly reducing cooking time.

- Traditional Braising - Involves cooking at low temperatures (around 275degF to 325degF) for 2 to 4 hours or more.

- Pressure Braising - Uses a sealed pressure cooker to cut cooking times by up to 70% while retaining moisture and flavor.

- Time Efficiency - Pressure braising is ideal for busy kitchens seeking tenderness without extended wait times.

Understanding the differences between these methods helps chefs choose the best technique for flavor and schedule constraints.

What is Pressure Braising?

Pressure braising is a cooking method that combines braising and pressure cooking to significantly reduce cooking time while maintaining tender, flavorful results. Unlike traditional braising, which relies on slow simmering, pressure braising uses sealed high-pressure conditions to cook food much faster.

- Faster cooking time - Pressure braising can cut braising times by up to 70%, making it ideal for busy kitchens.

- Retention of flavors - The sealed environment traps moisture and flavors, enhancing taste and tenderness.

- Energy efficient - Shorter cooking duration results in less energy consumption compared to slow braising.

Key Differences Between Braising and Pressure Braising

Braising involves cooking food slowly in liquid at low temperatures, typically taking several hours to tenderize tougher cuts of meat. Pressure braising uses a sealed pressure cooker, significantly reducing cooking time by increasing the boiling point of liquid and trapping steam. The key difference lies in time efficiency, with pressure braising achieving similar tenderness in a fraction of the time compared to traditional braising.

Time Efficiency in Braising: What to Expect

How does pressure braising compare to traditional braising in terms of time efficiency? Pressure braising significantly reduces cooking time by using high pressure to raise the boiling point of water, allowing tougher cuts of meat to become tender in under an hour. Traditional braising typically requires several hours, making pressure braising ideal for faster meal preparation without sacrificing flavor.

Pressure Braising: Speeding Up Cooking Times

| Pressure Braising | Uses high-pressure steam to cook food faster while maintaining moisture and tenderness; reduces cooking time by up to 70% compared to traditional braising. |

| Traditional Braising | Involves slow cooking in liquid at low temperatures over several hours; optimal for developing deep flavors but more time-consuming. |

| Time Efficiency | Pressure braising significantly cuts down cooking time, transforming dishes that typically require 3-4 hours into meals ready in under an hour without sacrificing texture or taste. |

Comparing Flavor Development: Braising vs Pressure Braising

Braising utilizes low, slow cooking over several hours to develop deep, complex flavors through gradual Maillard reactions and collagen breakdown. Pressure braising significantly reduces cooking time by increasing temperature and pressure, but this rapid process can result in less nuanced flavor development.

Traditional braising promotes richer taste and tender texture by allowing spices and aromatics to infuse over time, enhancing the savory profile of meats and vegetables. Pressure braising offers convenience and efficiency, yet the accelerated method may yield a less layered flavor compared to classic slow braising techniques.

Texture Results: Slow Braise vs Pressure Braise

Slow braising allows collagen and connective tissues in meat to break down gradually, resulting in a tender texture with rich, deep flavors. The extended cooking time promotes even heat distribution, preserving the integrity of delicate cuts.

Pressure braising significantly reduces cooking time by using high-pressure steam to tenderize meat quickly, but it can sometimes produce a slightly firmer texture compared to slow braising. This method is ideal for efficient meal preparation without sacrificing essential tenderness in tougher cuts.

Equipment Needed for Braising and Pressure Braising

Braising requires a heavy, lidded pot such as a Dutch oven to allow slow cooking at low temperatures, while pressure braising uses a specialized pressure cooker that significantly reduces cooking time by increasing the internal pressure. The equipment for pressure braising must be sturdy and capable of safely maintaining high pressure, which adds to its upfront cost but improves time efficiency. Traditional braising cookware is more versatile and often found in standard kitchens, whereas pressure cookers are optimized for faster results with less hands-on monitoring.

Optimal Dishes for Each Method

Braising is ideal for tougher cuts like brisket and short ribs, allowing flavors to develop slowly over several hours. Pressure braising reduces cooking time significantly, making it perfect for weeknight meals requiring tender results quickly.

- Braising suits large, tough cuts - Slow, low-heat cooking breaks down connective tissue, enhancing flavor and texture.

- Pressure braising accelerates cooking - High pressure and heat drastically cut down the time needed to tenderize meats.

- Choice depends on schedule and texture preference - Longer braising yields richer depth, while pressure braising prioritizes efficiency with good tenderness.

Related Important Terms

Rapid-cycle braising

Rapid-cycle braising significantly reduces cooking time compared to traditional braising by utilizing higher pressure and temperature to break down connective tissue faster, achieving tender results in under an hour. This method outperforms conventional pressure braising by optimizing heat transfer and moisture retention, making it ideal for commercial kitchens seeking efficient time management without sacrificing flavor.

Flash pressure braising

Flash pressure braising significantly reduces cooking time compared to traditional braising by using high pressure and elevated temperature to tenderize meat quickly, preserving moisture and enhancing flavor. This method optimizes time efficiency without compromising texture, making it ideal for fast-paced professional kitchens.

Turbo braise method

Turbo braise method reduces cooking time by combining high heat and pressure, outperforming traditional braising which relies on slow, low-temperature cooking. This technique preserves moisture and tenderness while significantly accelerating the process, making it the most time-efficient option among braising methods.

Accelerated collagen conversion

Pressure braising significantly accelerates collagen conversion compared to traditional braising by utilizing high pressure and temperature, reducing cooking time from several hours to under an hour. This method ensures faster tenderization of tough cuts, optimizing time efficiency without compromising flavor or texture.

Pressure-drop flavor extraction

Pressure braising significantly reduces cooking time by using high pressure to raise the boiling point of liquid, allowing faster heat penetration and quicker flavor extraction from tougher cuts of meat. Unlike traditional braising, pressure braising enhances the release of collagen and intensifies the depth of flavors while maintaining moisture, resulting in tender, richly flavored dishes in a fraction of the time.

Express braise analytics

Express braise analytics reveal that pressure braising reduces cooking time by up to 70% compared to traditional braising while maintaining similar flavor profiles and moisture retention. This time efficiency makes pressure braising ideal for commercial kitchens seeking rapid tenderization without compromising dish quality.

Instantaneous liquid reduction

Braising requires low and slow cooking to tenderize tough cuts, resulting in gradual liquid reduction over several hours, while pressure braising uses high pressure and temperature to dramatically accelerate cooking time, achieving near-instantaneous liquid reduction and intense flavor concentration. Pressure braising enhances time efficiency by combining rapid heat transfer and sealed environment, minimizing evaporation and allowing flavors to intensify in a fraction of the time compared to traditional braising methods.

Precision pressure-switch technique

Braising typically requires several hours of low and slow cooking to tenderize tough cuts, while pressure braising utilizes the precision pressure-switch technique to drastically reduce cooking time by maintaining exact pressure levels for optimal heat penetration. This method enhances time efficiency without compromising flavor or texture, making it ideal for both home cooks and professional chefs seeking precise control and faster results.

Time-compression umami release

Pressure braising significantly reduces cooking time compared to traditional braising by using high pressure to rapidly break down connective tissues, accelerating umami release and flavor development. This time-compression technique enhances tenderness and rich savory notes in a fraction of the time, making it ideal for efficient, flavor-packed meals.

Braising vs Pressure braising for time efficiency. Infographic

cookingdiff.com

cookingdiff.com