Enamel pots offer excellent heat retention with a non-reactive surface that prevents food from sticking during braising, making them ideal for slow-cooked meals requiring even heat distribution. Chamba pots, traditional clay cookware, provide natural moisture retention and a unique earthy flavor to braised dishes, enhancing taste through porous material that gently steams food. Choosing between enamel and Chamba pots depends on whether durability and ease of cleaning or authentic flavor infusion and moisture control are prioritized in braising.

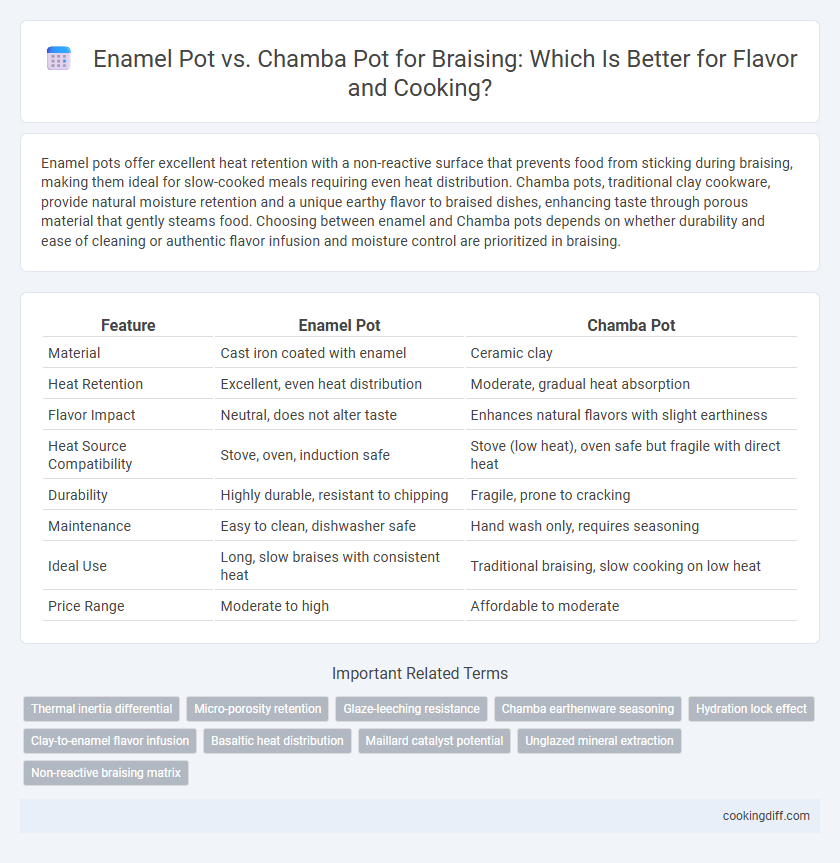

Table of Comparison

| Feature | Enamel Pot | Chamba Pot |

|---|---|---|

| Material | Cast iron coated with enamel | Ceramic clay |

| Heat Retention | Excellent, even heat distribution | Moderate, gradual heat absorption |

| Flavor Impact | Neutral, does not alter taste | Enhances natural flavors with slight earthiness |

| Heat Source Compatibility | Stove, oven, induction safe | Stove (low heat), oven safe but fragile with direct heat |

| Durability | Highly durable, resistant to chipping | Fragile, prone to cracking |

| Maintenance | Easy to clean, dishwasher safe | Hand wash only, requires seasoning |

| Ideal Use | Long, slow braises with consistent heat | Traditional braising, slow cooking on low heat |

| Price Range | Moderate to high | Affordable to moderate |

Introduction: Enamel Pot vs Chamba Pot for Braising

Choosing between an enamel pot and a Chamba pot significantly affects the braising outcome due to their material properties and heat retention capabilities. Each pot unique design influences moisture control and flavor development during the braising process.

- Enamel pot offers non-reactive cooking surface - It prevents metal leaching and maintains the purity of acidic ingredients in braised dishes.

- Chamba pot is made of clay with porous texture - Its natural porosity allows slow evaporation, enhancing moisture retention for tender meat.

- Enamel pots provide excellent heat distribution - They ensure even cooking temperatures, reducing hot spots and burning risks during braising.

Both enamel and Chamba pots provide unique advantages that cater to different culinary preferences and braising techniques.

Material Composition and Heat Retention

Enamel pots are made from cast iron coated with a smooth, non-porous layer of enamel, providing excellent heat retention and even cooking while preventing rust. Chamba pots, crafted from clay, offer natural thermal insulation that retains moisture effectively but require careful handling to avoid cracking.

Cast iron enamel pots distribute heat uniformly and maintain consistent temperatures, making them ideal for prolonged braising. Chamba clay pots absorb and release heat slowly, enhancing flavor infusion but needing gradual heating to prevent damage. Both materials excel in heat retention, with enamel pots offering durability and Chamba pots delivering unique earthy flavors.

Flavor Development During Braising

How does the choice between an enamel pot and a Chamba pot affect flavor development during braising? Enamel pots provide even heat distribution and a non-reactive surface, preserving the natural flavors of ingredients without imparting additional taste. Chamba pots, made from clay, enhance flavor complexity by allowing slow evaporation and micro-oxygenation, which deepens the braised dish's richness over extended cooking times.

Cooking Performance: Moisture and Evenness

Enamel pots provide excellent moisture retention due to their non-porous surface, ensuring even heat distribution that prevents hot spots during braising. Chamba pots, made from porous clay, naturally absorb and release moisture, enhancing flavor but requiring careful temperature control for consistent heat. Both pots excel in braising, with enamel pots offering uniform heat and Chamba pots promoting a unique moisture balance that enriches the dish's depth.

Durability and Longevity

| Enamel Pot | Enamel pots offer excellent durability due to their protective glass coating, resisting rust and corrosion during braising. The enamel surface prevents metal leaching, but can chip or crack with heavy impact, affecting longevity. Proper care ensures enamel pots maintain their structural integrity and performance over years of use. |

| Chamba Pot | Chamba pots, handcrafted from heavy-duty cast iron, are renowned for exceptional durability, with the ability to withstand high heat and continuous use without damage. They develop a natural non-stick patina that enhances longevity and flavor over time, often lasting generations. However, Chamba pots require regular seasoning and careful maintenance to prevent rust and cracking during braising. |

Ease of Maintenance and Cleaning

Enamel pots are easier to clean due to their smooth, non-porous surface that resists staining and odor absorption. Chamba pots require more careful maintenance as their porous clay material can absorb oils and flavors, necessitating thorough cleaning and drying.

- Enamel pot non-porous surface - Prevents food particles from sticking, simplifying the cleaning process.

- Chamba pot porous material - Absorbs oils and odors, leading to more involved cleaning routines to avoid residue buildup.

- Enamel pot dishwasher safe - Most enamel pots can be cleaned in dishwashers without damage, unlike fragile Chamba pots.

Traditional Uses in Braising Recipes

Enamel pots are prized for their non-reactive surfaces and even heat distribution, making them ideal for slow braising of meats and vegetables in acidic sauces. Chamba pots, made from unglazed clay, excel in retaining moisture and infusing dishes with earthy flavors, traditionally favored for long, slow-cooked stews in Latin American cuisine.

The enamel coating prevents food from sticking and allows for easy cleaning, which is beneficial in recipes requiring frequent stirring or deglazing. Chamba pots, on the other hand, promote gentle steaming and tenderizing by naturally regulating moisture, enhancing the depth of flavor in rustic braised dishes.

Compatibility with Modern Cooktops

Enamel pots are highly compatible with modern cooktops, including induction, gas, and electric stoves, due to their magnetic base and durable coating. They heat evenly and are easy to clean, making them a popular choice for braising on contemporary kitchen appliances.

Chamba pots, traditionally made from clay, require careful handling and may not perform optimally on induction cooktops without a diffuser. They excel on gas and electric stoves, offering unique heat retention and flavor enhancement but need more maintenance to prevent cracking on modern surfaces.

Price Comparison and Value

Enamel pots typically offer a more affordable price point compared to traditional Chamba pots, making them accessible for everyday use in braising. While Chamba pots command a higher price due to their handcrafted quality and superior heat retention, they provide exceptional value for slow-cooked dishes. Investing in a Chamba pot ensures durability and enhanced flavor development, often justifying the initial cost over time.

Related Important Terms

Thermal inertia differential

Enamel pots provide moderate thermal inertia with even heat distribution ideal for consistent braising temperatures, while Chamba pots exhibit higher thermal inertia due to their thick clay construction, retaining and slowly releasing heat for prolonged, gentle cooking. This thermal inertia differential influences moisture retention and flavor development, making enamel pots suitable for quick braises and Chamba pots preferred for slow, deeply infused dishes.

Micro-porosity retention

Enamel pots provide a smooth, non-porous surface that prevents moisture absorption, ensuring consistent heat retention during braising, while Chamba pots feature micro-porosity that allows gradual moisture release and enhances flavor depth through natural steam circulation. The micro-porous structure of Chamba clay improves food texture and tenderness, but requires careful seasoning and maintenance to preserve its braising efficiency.

Glaze-leeching resistance

Enamel pots provide superior glaze-leeching resistance during braising, preventing metal ions from seeping into food and ensuring safe, non-reactive cooking. In contrast, traditional Chamba pots, made from unglazed clay, lack this resistance, increasing the risk of mineral leaching under prolonged heat and acidic ingredients.

Chamba earthenware seasoning

Chamba pots, made from natural earthenware, require seasoning to enhance their porosity, strengthen the vessel, and prevent cracking during braising, making them ideal for slow, even heat distribution. Unlike enamel pots with a non-porous coating, properly seasoned Chamba pots develop a natural non-stick surface that retains moisture and imparts earthy flavors to braised dishes.

Hydration lock effect

Enamel pots excel in braising by providing a tight seal that enhances moisture retention, effectively locking in hydration to tenderize meat and infuse flavors. Chamba pots, made from porous clay, naturally absorb and release moisture, creating a self-basting effect that maintains hydration through slow, even cooking.

Clay-to-enamel flavor infusion

Enamel pots provide even heat distribution and a non-reactive surface that preserves the pure flavors of braised dishes without imparting any additional taste, while Chamba pots, made from unglazed clay, actively enhance flavor infusion by releasing earthy, mineral-rich notes during slow cooking. The porous nature of Chamba clay allows moisture and marinades to penetrate deeper into the food, creating a distinct, rustic aroma and taste that enamel pots cannot replicate.

Basaltic heat distribution

Enamel pots offer even heat distribution with their cast iron construction, but Chamba pots, made from basaltic clay, excel in retaining and distributing heat uniformly due to their natural mineral composition. The basaltic heat retention in Chamba pots ensures consistent moisture and flavor infusion during braising, outperforming enamel pots in maintaining low and slow cooking temperatures.

Maillard catalyst potential

Enamel pots provide excellent heat retention and even temperature distribution, which enhances the Maillard reaction by maintaining consistent high heat ideal for browning during braising. Chamba pots, made from clay, offer slow, gentle heat diffusion that promotes gradual caramelization but may limit the Maillard reaction's intensity due to less direct high-temperature contact.

Unglazed mineral extraction

Enamel pots feature a glazed interior that prevents direct contact with minerals, reducing the extraction of iron and other trace elements during braising, while unglazed Chamba pots are made from natural clay that allows for slow mineral leaching, enhancing flavor complexity and nutrient content. The porous surface of Chamba pots facilitates moisture retention and mineral exchange, making them ideal for traditional braising techniques that benefit from mineral-rich cooking environments.

Enamel pot vs Chamba pot for braising. Infographic

cookingdiff.com

cookingdiff.com