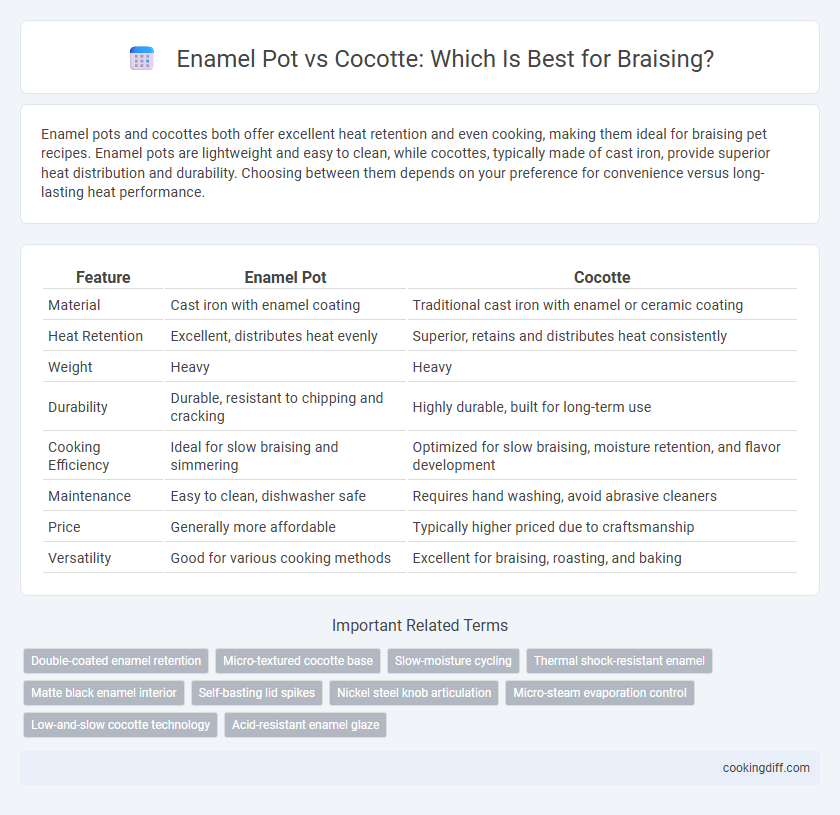

Enamel pots and cocottes both offer excellent heat retention and even cooking, making them ideal for braising pet recipes. Enamel pots are lightweight and easy to clean, while cocottes, typically made of cast iron, provide superior heat distribution and durability. Choosing between them depends on your preference for convenience versus long-lasting heat performance.

Table of Comparison

| Feature | Enamel Pot | Cocotte |

|---|---|---|

| Material | Cast iron with enamel coating | Traditional cast iron with enamel or ceramic coating |

| Heat Retention | Excellent, distributes heat evenly | Superior, retains and distributes heat consistently |

| Weight | Heavy | Heavy |

| Durability | Durable, resistant to chipping and cracking | Highly durable, built for long-term use |

| Cooking Efficiency | Ideal for slow braising and simmering | Optimized for slow braising, moisture retention, and flavor development |

| Maintenance | Easy to clean, dishwasher safe | Requires hand washing, avoid abrasive cleaners |

| Price | Generally more affordable | Typically higher priced due to craftsmanship |

| Versatility | Good for various cooking methods | Excellent for braising, roasting, and baking |

Introduction to Braising: Why Cookware Matters

Braising requires cookware that ensures even heat distribution and retains moisture effectively. Enamel pots offer a non-reactive surface ideal for acidic ingredients, while cocottes, often made from cast iron with an enamel coating, excel at maintaining steady heat for long cooking times. Choosing the right pot can significantly impact the tenderness and flavor development in braised dishes.

What is an Enamel Pot?

| Enamel Pot Definition | An enamel pot is a cast iron or steel cookware coated with a smooth, durable layer of enamel that prevents rust and provides a non-reactive cooking surface ideal for braising. The enamel coating allows for even heat distribution and retention, essential for the slow-cooking process involved in braising tougher cuts of meat. These pots are resistant to acidic ingredients and do not require seasoning, making them low-maintenance and versatile for oven and stovetop use. |

Defining the Cocotte: Features and Designs

The cocotte is a versatile cast iron pot renowned for its excellent heat retention and even cooking, ideal for slow braising. It typically features a tight-fitting lid and an enamel coating that prevents rust and enhances durability.

- Material Composition - Cocottes are commonly made from enameled cast iron, which distributes heat evenly and maintains consistent temperature for thorough braising.

- Lid Design - The heavy, tight-fitting lid helps trap moisture and flavors, creating a self-basting effect essential for tenderizing meat.

- Shape and Size - Cocottes often come in oval or round shapes, offering versatility to accommodate various cuts of meat and braising techniques.

Heat Distribution: Enamel Pot vs Cocotte

Enamel pots offer even heat distribution due to their heavy-duty cast iron core, which helps maintain a consistent temperature throughout the braising process. This ensures that food cooks uniformly and retains moisture effectively.

Cocottes, typically made from cast iron with an enamel coating, provide excellent heat retention and slow heat release, ideal for long, low-temperature cooking. Their tight-fitting lids also help trap steam, enhancing flavor development during braising.

Moisture Retention and Cooking Performance

Enamel pots and cocottes excel in braising due to their superior heat retention and even cooking surface. Cocottes, often made of cast iron, provide exceptional moisture retention, resulting in tender and flavorful dishes.

- Enamel Pot Durability - Enamel coating prevents rust and allows easy cleaning while maintaining heat distribution.

- Cocotte Heat Retention - Heavy cast iron construction retains heat evenly, crucial for slow braising.

- Moisture Sealing - Tight-fitting lids on cocottes trap steam effectively, preserving moisture in the food.

Both cookware types enhance braising by ensuring consistent temperature and moisture retention for optimal cooking results.

Durability and Longevity Comparison

Enamel pots offer excellent resistance to rust and corrosion, ensuring long-term durability when properly cared for. Cocottes, typically made from cast iron with an enamel coating, combine robust heat retention with a sturdy exterior that withstands heavy use over many years. Both cookware types excel in longevity, but cocottes often provide superior heat distribution and durability due to their thicker cast iron construction.

Ease of Cleaning: Maintenance Differences

Enamel pots feature a smooth, non-porous surface that resists staining and makes cleaning simpler after braising. Their durable coating prevents food from sticking, reducing the need for intensive scrubbing.

Cocottes, often made of enameled cast iron, require careful maintenance to avoid chipping but offer excellent heat retention. Cleaning typically involves gentle hand washing to preserve the enamel's quality and prolong the cookware's lifespan.

Versatility in the Kitchen

Enamel pots offer excellent heat retention and durability, making them ideal for slow-cooking and braising tougher cuts of meat. Cocottes provide a traditional cast iron design that distributes heat evenly, enhancing flavor and texture during long cooking sessions.

The versatility of enamel pots extends beyond braising, suitable for simmering soups, stews, and even baking, thanks to their non-reactive coating and compatibility with various heat sources. Cocottes excel in kitchen versatility by transitioning seamlessly from stovetop to oven, perfect for one-pot meals and rustic presentations. Both cookware options bring unique advantages to braising, catering to different culinary needs and kitchen environments.

Price and Value Analysis

Enamel pots generally offer a lower price point compared to cocottes, making them accessible for budget-conscious cooks while still providing effective braising performance. Cocottes, often crafted from high-quality cast iron, command a higher initial investment but deliver superior durability and heat retention, enhancing long-term cooking value.

- Enamel Pot Affordability - Typically priced below premium cocottes, making them attractive for entry-level home chefs.

- Cocotte Durability - Constructed from cast iron, cocottes last longer and resist chipping better than many enamel alternatives.

- Value Retention - Higher upfront cost of cocottes is offset by their longevity and superior heat distribution in braising.

Related Important Terms

Double-coated enamel retention

Double-coated enamel pots provide superior heat retention and even distribution essential for effective braising, minimizing hot spots that can compromise texture. Compared to traditional cocottes, these enamel pots resist chipping and maintain a non-reactive surface, ensuring flavors remain pure throughout long, slow cooking processes.

Micro-textured cocotte base

A micro-textured cocotte base enhances heat retention and promotes even browning during braising, outperforming standard enamel pots by creating superior caramelization and moisture control. This textured surface ensures consistent heat distribution, resulting in tender, flavorful dishes with improved texture.

Slow-moisture cycling

Enamel pots provide excellent slow-moisture cycling due to their thick walls and tight-fitting lids that trap steam, creating an optimal environment for braising tender meats and vegetables. Cocottes, often made of cast iron with an enamel coating, enhance heat retention and even distribution, further preserving moisture and intensifying flavors throughout the slow cooking process.

Thermal shock-resistant enamel

Enamel pots with thermal shock-resistant enamel provide superior durability and evenly distribute heat, making them ideal for braising delicate cuts of meat without cracking under sudden temperature changes. Compared to traditional cocottes, these enamel pots offer enhanced resistance to thermal shock, ensuring longer lifespan and consistent cooking performance.

Matte black enamel interior

Matte black enamel interior in enamel pots offers superior resistance to staining and a non-reactive surface ideal for slow braising, while cocottes typically feature glossy interiors that may show wear over time. The matte finish enhances heat retention and distribution, ensuring even cooking and rich flavor development during long braising processes.

Self-basting lid spikes

Enamel pots with self-basting lid spikes continuously redistribute condensation during braising, enhancing moisture retention and flavor infusion throughout the cooking process. Cocottes, featuring these specialized lids, create an optimal cooking environment by evenly dripping liquid back onto the food, ensuring tender, succulent results without requiring additional basting.

Nickel steel knob articulation

Enamel pots with nickel steel knobs offer superior heat resistance and durability, maintaining a secure seal during braising to lock in moisture and flavors effectively. Cocottes featuring nickel steel knob articulation provide enhanced ergonomic control for precise lid positioning, improving heat retention and even cooking essential for optimal braising results.

Micro-steam evaporation control

Enamel pots provide precise micro-steam evaporation control during braising, preserving moisture and enhancing flavor development by maintaining a consistent internal environment. Cocottes, often heavier with tighter lids, excel at trapping steam but may limit evaporation control, resulting in slightly different moisture retention dynamics ideal for slow, even cooking.

Low-and-slow cocotte technology

A low-and-slow cocotte offers superior heat retention and even distribution crucial for braising, maintaining consistent moisture and tenderness in meats. Unlike enamel pots, cocottes made from cast iron excel in sustaining steady temperatures over extended periods, optimizing the braising process for optimal flavor development.

Enamel Pot vs Cocotte for braising. Infographic

cookingdiff.com

cookingdiff.com