Stainless steel pots offer even heat distribution and durability, making them ideal for consistent braising results, while sand pots excel in heat retention and impart a unique flavor by slow-cooking at lower temperatures. Stainless steel is easier to clean and more resistant to rust, whereas sand pots require careful handling to avoid cracking and may need seasoning for long-term use. Choosing between them depends on your preference for maintenance ease versus traditional cooking qualities.

Table of Comparison

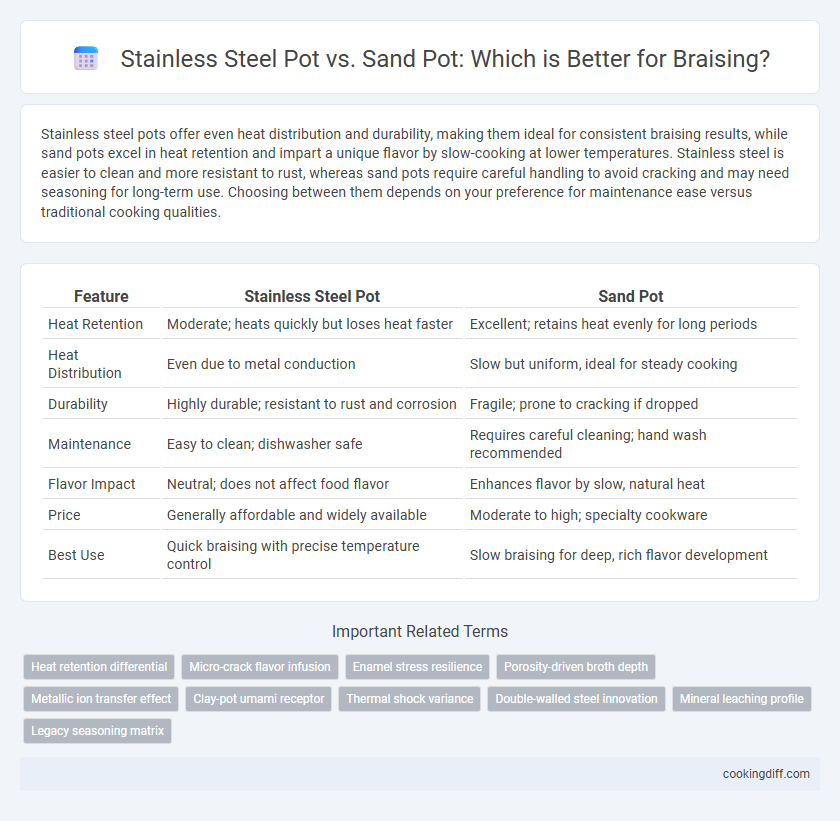

| Feature | Stainless Steel Pot | Sand Pot |

|---|---|---|

| Heat Retention | Moderate; heats quickly but loses heat faster | Excellent; retains heat evenly for long periods |

| Heat Distribution | Even due to metal conduction | Slow but uniform, ideal for steady cooking |

| Durability | Highly durable; resistant to rust and corrosion | Fragile; prone to cracking if dropped |

| Maintenance | Easy to clean; dishwasher safe | Requires careful cleaning; hand wash recommended |

| Flavor Impact | Neutral; does not affect food flavor | Enhances flavor by slow, natural heat |

| Price | Generally affordable and widely available | Moderate to high; specialty cookware |

| Best Use | Quick braising with precise temperature control | Slow braising for deep, rich flavor development |

Introduction to Braising: Why Cookware Matters

Braising requires even heat distribution and moisture retention, making cookware choice crucial for flavor and texture. Stainless steel pots and sand pots offer distinct advantages in handling the slow-cooking process essential to braising.

- Stainless Steel Pot - Provides durability and a non-reactive surface, ensuring even heat conduction and easy maintenance.

- Sand Pot - Known for superior heat retention and gradual heat release, ideal for slow, consistent cooking.

- Moisture Control - Both types influence how moisture is retained during braising, affecting the tenderness and juiciness of the dish.

Choosing the right pot enhances the braising experience by maintaining precise temperature control and optimal moisture balance.

Stainless Steel Pots: Key Features for Braising

Stainless steel pots offer excellent heat conductivity and durability, making them ideal for consistent braising temperatures. Their non-reactive surface ensures that acidic ingredients do not alter the flavor of the dish.

These pots provide even heat distribution which helps in slow cooking and tenderizing meat effectively. Their tight-fitting lids retain moisture, essential for the braising process. Stainless steel is also easy to clean and resistant to staining, maintaining its appearance after repeated use.

Sand Pots: Traditional Advantages in Braising

Sand pots maintain even heat distribution and excellent heat retention, which are crucial for the slow, consistent cooking process involved in braising. Their porous clay material absorbs and radiates heat uniformly, enhancing the flavor development of meats and vegetables.

Traditional sand pots also promote gentle moisture evaporation, preserving the dish's tenderness and juiciness. Unlike stainless steel pots, sand pots create a natural cooking environment that enhances the depth and richness of braised recipes.

Heat Distribution: Stainless Steel vs Sand Pot

Stainless steel pots offer rapid heat conduction and maintain consistent temperatures ideal for precise braising. Sand pots provide slow, even heat distribution, enhancing flavor development through gentle cooking over time.

- Stainless Steel Pot - Enables quick and uniform heating, reducing cooking time and allowing better temperature control.

- Sand Pot - Retains heat longer with gradual temperature changes, ideal for slow-cooked, tender dishes.

- Heat Distribution - Stainless steel's fast heat transfer contrasts with sand pot's ability to distribute heat gently and steadily during braising.

Flavor Development: Which Pot Reigns Supreme?

Stainless steel pots offer even heat distribution and durability, allowing precise temperature control that enhances the Maillard reaction crucial for deep flavor development in braising. Their non-porous surface prevents absorption of flavors, ensuring a clean taste profile throughout the cooking process.

Sand pots, especially those made from clay or earthenware, excel at retaining moisture and providing gentle, consistent heat that slowly infuses ingredients, enriching the braised dish's complexity. The porous nature of sand pots allows subtle exchange of steam and aromas, contributing to a unique, robust flavor signature favored in traditional braising techniques.

Moisture Retention: Sand Pot and Stainless Steel Compared

Sand pots excel in moisture retention due to their porous clay material, which absorbs and slowly releases steam, enhancing flavor and tenderness in braised dishes. Stainless steel pots, with their non-porous and conductive surfaces, tend to retain less moisture but offer superior heat distribution and durability. Choosing between the two depends on whether moisture retention or consistent heat control is prioritized for the braising process.

Durability and Maintenance: Pros and Cons

Which pot offers better durability and easier maintenance for braising, stainless steel or sand pot? Stainless steel pots are highly durable, resistant to rust and corrosion, and easy to clean due to their non-porous surface. Sand pots, while excellent for heat retention, require careful maintenance to prevent cracking and can be more challenging to clean because of their porous texture.

Compatibility with Modern Stovetops

| Stainless Steel Pot Compatibility | Highly compatible with all modern stovetops including induction, gas, electric, and ceramic due to its magnetic properties and even heat distribution. |

| Sand Pot Compatibility | Best suited for gas and electric stovetops; generally incompatible with induction cooktops because of the pot's non-magnetic clay material. |

| Practical Considerations | Stainless steel pots offer versatility and quick heating, whereas sand pots require cautious handling and are limited to certain heat sources for optimal braising results. |

Culinary Applications: Best Dishes for Each Pot

Stainless steel pots excel in braising acidic dishes like tomato-based stews due to their non-reactive surfaces, while sand pots retain heat evenly, making them ideal for slow-cooked, moisture-rich recipes. Each pot enhances specific culinary techniques, influencing flavor development and texture in braised dishes.

- Stainless steel pot for acidic braises - Resists corrosion from acidic ingredients, perfect for tomato and wine-based recipes.

- Sand pot for even heat distribution - Maintains consistent temperature, ideal for slow-cooked meats and vegetable braises.

- Culinary versatility - Stainless steel handles a wider range of braises quickly, whereas sand pots deepen flavor through gradual heat absorption.

Related Important Terms

Heat retention differential

Stainless steel pots offer rapid heat conduction but lower heat retention compared to sand pots, which excel in maintaining consistent, even heat ideal for slow braising. The superior thermal mass of sand pots ensures prolonged heat distribution, reducing the risk of hot spots and enhancing flavor development during the braising process.

Micro-crack flavor infusion

Stainless steel pots offer durability and non-reactive surfaces but may cause uneven heat distribution, limiting micro-crack formation critical for deep flavor infusion in braising. Sand pots excel in retaining and diffusing heat evenly, promoting micro-cracks in food fibers that enhance the absorption and development of rich, complex flavors.

Enamel stress resilience

Stainless steel pots with enamel coating demonstrate superior stress resilience during braising due to their ability to withstand high temperatures without cracking or chipping, unlike traditional sand pots that are more prone to enamel damage under thermal stress. This durability ensures consistent heat distribution and a longer lifespan, making stainless steel enamel pots a more reliable choice for braising techniques.

Porosity-driven broth depth

Stainless steel pots offer a non-porous surface that prevents broth absorption, maintaining a clean, concentrated flavor ideal for precise braising. Sand pots, with their porous structure, absorb and slowly release liquids, enriching broth depth by intensifying flavors through gradual evaporation and reabsorption during cooking.

Metallic ion transfer effect

Stainless steel pots prevent metallic ion transfer during braising, ensuring the food's flavor remains pure and untainted, while sand pots may release trace minerals that subtly alter the dish's taste and nutritional profile. The inert properties of stainless steel make it ideal for maintaining chemical stability in acidic and long-cooked braised foods compared to porous sand pots.

Clay-pot umami receptor

Stainless steel pots offer even heat distribution and durability for braising, but sand pots, particularly clay pots, enhance umami receptor activation by retaining moisture and releasing earthy minerals that deepen flavor complexity. Clay-pot braising fosters a unique chemical interaction between the porous material and ingredients, amplifying savory taste profiles often less pronounced in stainless steel cookware.

Thermal shock variance

Stainless steel pots exhibit high thermal conductivity but are more prone to thermal shock due to rapid temperature changes, potentially leading to warping or damage when exposed to sudden heat fluctuations. Sand pots, composed of porous clay material, offer superior thermal shock resistance by gradually distributing heat, making them ideal for slow, even braising without abrupt temperature variation risks.

Double-walled steel innovation

Double-walled stainless steel pots offer superior heat retention and even distribution compared to traditional sand pots, enhancing the braising process by maintaining consistent low temperatures essential for tenderizing meats. This innovation reduces hotspots and improves energy efficiency, making stainless steel double-walled cookware a modern, durable alternative to heavy, fragile sand pots in braising applications.

Mineral leaching profile

Stainless steel pots exhibit minimal mineral leaching during braising, preserving the integrity of the food's flavor and nutritional content, while sand pots, composed of natural clay, may release trace minerals such as calcium and magnesium that can subtly enhance the dish's taste profile. The choice between these pots impacts both the chemical interaction with acidic braising liquids and the mineral enrichment of the final meal.

Stainless steel pot vs sand pot for braising. Infographic

cookingdiff.com

cookingdiff.com