Broiling uses intense radiant heat from above, creating a crispy, charred surface ideal for achieving traditional grilled texture. Infrared burners emit high-energy wavelengths that penetrate food quickly, producing evenly browned and juicy results without drying out. While broiling excels at quick searing, infrared burners offer more precise temperature control for consistent grilling outcomes.

Table of Comparison

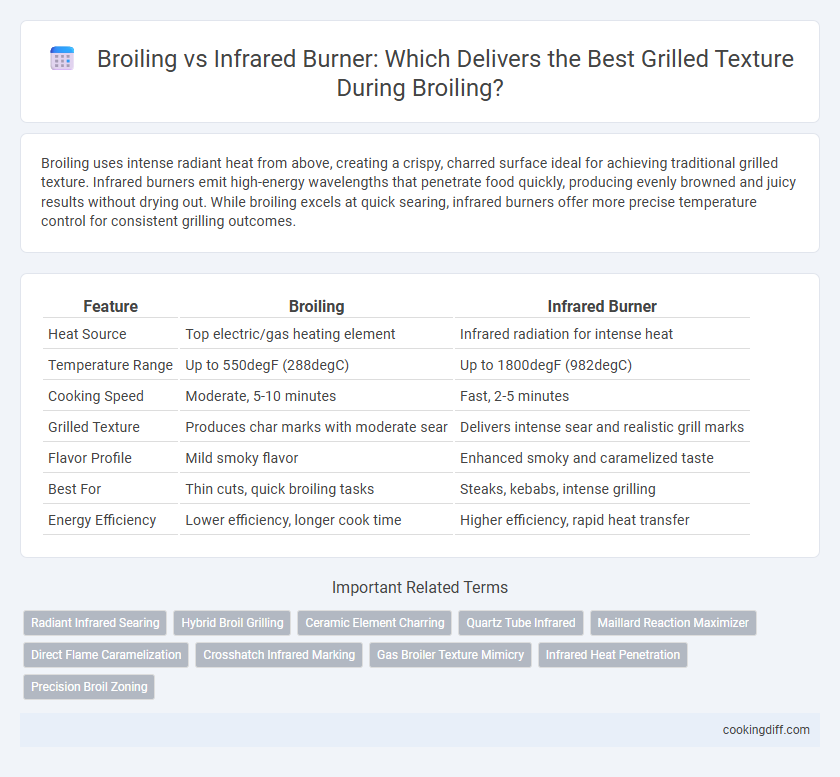

| Feature | Broiling | Infrared Burner |

|---|---|---|

| Heat Source | Top electric/gas heating element | Infrared radiation for intense heat |

| Temperature Range | Up to 550degF (288degC) | Up to 1800degF (982degC) |

| Cooking Speed | Moderate, 5-10 minutes | Fast, 2-5 minutes |

| Grilled Texture | Produces char marks with moderate sear | Delivers intense sear and realistic grill marks |

| Flavor Profile | Mild smoky flavor | Enhanced smoky and caramelized taste |

| Best For | Thin cuts, quick broiling tasks | Steaks, kebabs, intense grilling |

| Energy Efficiency | Lower efficiency, longer cook time | Higher efficiency, rapid heat transfer |

Introduction to Broiling and Infrared Burners

Broiling uses direct radiant heat from an overhead element to cook food quickly, creating a caramelized, grilled texture. Infrared burners emit intense, focused heat that sears food efficiently, locking in moisture while providing even cooking. Both methods enhance grilled textures but differ in heat source and intensity, impacting flavor and cooking speed.

How Broiling Works: Traditional Oven Method

Broiling uses intense, direct heat from an overhead element in a traditional oven to cook food quickly and create a crispy, grilled texture. The heat source remains fixed above the food, allowing it to brown and caramelize efficiently without intense smoke production.

- Direct radiant heat - Broiling exposes food to high temperatures from the oven's top heating element, typically around 500degF or higher.

- Close proximity cooking - Food is placed near the broiler for rapid surface cooking and texture development.

- Moisture retention - Broiling allows juices to remain inside food, enhancing flavor while creating a crispy exterior.

This traditional oven broiling method delivers a grilled texture by combining high heat and short cooking time without open flames.

What Is an Infrared Burner?

An infrared burner uses advanced technology to emit intense, focused heat through infrared radiation, creating a high-temperature cooking environment ideal for achieving a crispy, grilled texture. Unlike traditional broiling, which relies on direct radiant heat from an overhead element, infrared burners deliver rapid and even heat distribution, enhancing searing and caramelization. This efficient heat transfer method makes infrared burners popular for grilling meats and vegetables while preserving juiciness and flavor.

Heat Distribution: Broiling vs Infrared Burner

Broiling uses direct radiant heat from above, resulting in uneven heat distribution that can cause hotspots and inconsistent cooking. Infrared burners emit intense, focused heat that penetrates food quickly, offering more uniform heat distribution across the cooking surface.

Infrared burners maintain a consistent temperature, enhancing the grilled texture by searing meat evenly and locking in juices. Broiling may require frequent adjustment of food placement to prevent burning or undercooking due to its variable heat intensity.

Achieving Grilled Texture: Key Differences

| Broiling | Uses high heat from an overhead source, typically inside an oven, to cook food quickly and create a crispy, charred surface. |

| Infrared Burner | Generates intense, direct heat through infrared radiation, producing even cooking and a seared texture similar to outdoor grilling. |

| Grilled Texture Differences | Broiling often results in uneven searing due to heat distribution, while infrared burners provide a more consistent char and grill marks, enhancing flavor and texture. |

Cooking Speed: Infrared Burner vs Standard Broiler

Infrared burners cook food significantly faster than standard broilers due to their intense heat output and focused energy transfer. This rapid cooking preserves juiciness while creating a superior grilled texture compared to the slower, less direct heat of traditional broilers.

- Infrared Burner Speed - Infrared burners can reach temperatures above 1000degF, reducing cooking time by up to 50% compared to standard broilers.

- Standard Broiler Heat - Conventional broilers typically operate around 500-550degF, resulting in longer cooking times and less effective surface searing.

- Texture Quality - Faster cooking with infrared burners promotes better caramelization and crust formation for enhanced grilled texture.

Flavor Development: Caramelization and Searing

Broiling uses direct high heat from above to achieve intense caramelization and searing, enhancing flavor through Maillard reactions. Infrared burners generate concentrated, radiant heat that penetrates food quickly, resulting in a distinct grilled texture with deep searing.

- Broiling heat source - Radiant heat from an overhead element creates surface caramelization by rapidly browning sugars and proteins.

- Infrared burner intensity - Emits focused radiant energy that sears the exterior effectively while locking in juices for enhanced flavor.

- Flavor impact - Broiling develops complex caramelized notes whereas infrared burners provide a robust, smoky grilled taste.

Energy Efficiency Comparison

Which method offers better energy efficiency for achieving a grilled texture: broiling or an infrared burner? Infrared burners typically consume less energy by reaching higher temperatures more quickly, providing faster cooking times. Broiling uses more energy overall because it relies on radiant heat that requires longer exposure to achieve the same grilled texture.

User Experience: Ease of Use and Control

Broiling offers direct heat from above, allowing users to easily control cooking intensity by adjusting the oven rack's distance. This method provides intuitive temperature settings, resulting in a hands-on grilling experience for achieving a charred texture.

Infrared burners deliver intense, even heat through radiant energy, requiring users to manage precise heat zones for optimal results. The control panel often includes digital settings, enhancing ease of use for consistent grilling performance.

Related Important Terms

Radiant Infrared Searing

Radiant infrared searing delivers intense, consistent heat that penetrates food quickly, creating a crisp grilled texture unmatched by traditional broiling methods. Unlike broiling's direct heat source, infrared burners emit focused radiant energy that caramelizes surface sugars efficiently, enhancing flavor and achieving perfect grill marks.

Hybrid Broil Grilling

Hybrid broil grilling combines the intense, direct heat of traditional broiling with the rapid, radiant heat of an infrared burner to achieve superior grilled texture characterized by crisp searing and juicy interior moisture retention. This method enhances flavor development and cooking efficiency by leveraging the infrared burner's high heat concentration while maintaining the broiler's ability to produce classic char marks and caramelization.

Ceramic Element Charring

Broiling with a ceramic element produces intense, even heat that enhances charring and caramelization, resulting in a superior grilled texture compared to infrared burners. Infrared burners generate high heat quickly but often lack the consistent radiant heat needed for optimal ceramic element charring and deep searing.

Quartz Tube Infrared

Quartz tube infrared burners deliver intense, consistent heat through infrared radiation, producing a superior grilled texture with quicker searing and enhanced caramelization compared to traditional broiling methods. This technology ensures even cooking and reduces flare-ups, making it ideal for achieving restaurant-quality char and juiciness on grilled foods.

Maillard Reaction Maximizer

Broiling and infrared burners both enhance the Maillard reaction, but infrared burners achieve higher surface temperatures faster, maximizing browning and creating a superior grilled texture. The intense direct heat from infrared burners triggers rapid caramelization of proteins and sugars, resulting in a more pronounced crust compared to traditional broiling.

Direct Flame Caramelization

Broiling achieves direct flame caramelization by exposing food to high heat from above, creating a crispy, charred texture ideal for grilling. Infrared burners use intense, focused heat that penetrates quickly, producing a uniformly caramelized surface with enhanced juiciness and flavor retention.

Crosshatch Infrared Marking

Broiling and infrared burners both achieve high heat for grilling, but the infrared burner excels at creating precise crosshatch infrared markings due to its intense, focused heat output. This method enhances the grilled texture with distinct sear lines and improved Maillard reaction, delivering superior flavor and visual appeal compared to traditional broiling.

Gas Broiler Texture Mimicry

Gas broilers deliver intense, direct heat that effectively mimics the char and caramelization typical of open-flame grilling, creating a distinctive grilled texture with prominent sear marks. Infrared burners, while offering precise temperature control and rapid heat-up, often produce a more uniform cooking surface, resulting in less pronounced texture variation compared to traditional gas broilers.

Infrared Heat Penetration

Infrared burners provide superior heat penetration by emitting intense infrared radiation that directly cooks food, resulting in evenly grilled textures with a crisp exterior and juicy interior. Broiling relies on radiant heat from above, which may cause surface charring but lacks the deep heat infusion characteristic of infrared burners.

Broiling vs Infrared Burner for Grilled Texture. Infographic

cookingdiff.com

cookingdiff.com