Broiling uses direct high heat from above to quickly sear the steak, creating a flavorful crust while maintaining juiciness inside. Infrared cooking emits intense radiant heat that penetrates the meat more evenly, producing faster cooking times and a consistent finish. Compared to broiling, infrared technology reduces flare-ups and enhances the steak's caramelization without overcooking the interior.

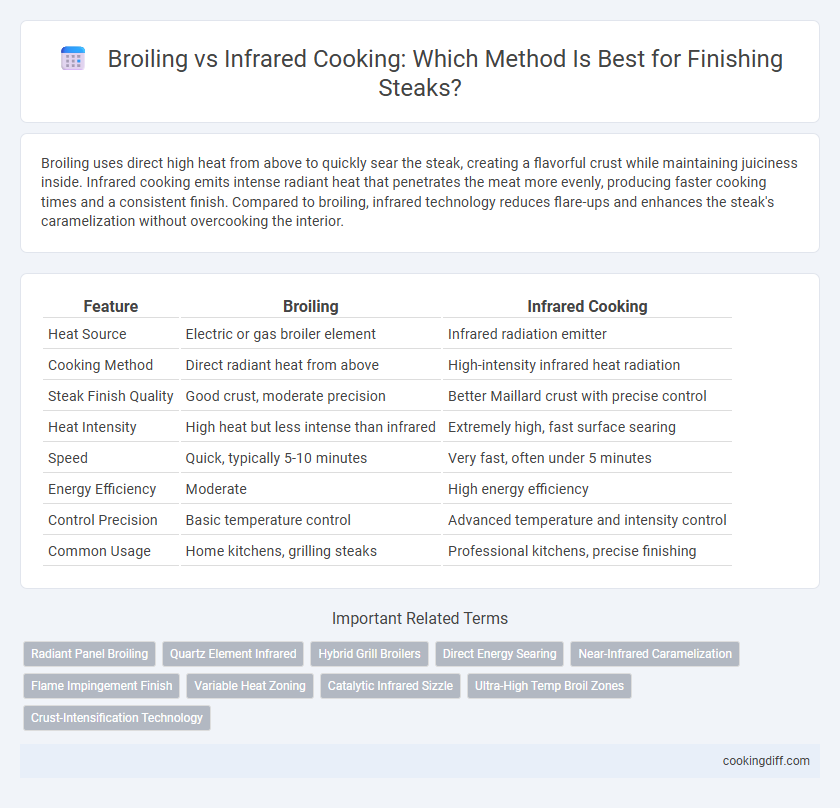

Table of Comparison

| Feature | Broiling | Infrared Cooking |

|---|---|---|

| Heat Source | Electric or gas broiler element | Infrared radiation emitter |

| Cooking Method | Direct radiant heat from above | High-intensity infrared heat radiation |

| Steak Finish Quality | Good crust, moderate precision | Better Maillard crust with precise control |

| Heat Intensity | High heat but less intense than infrared | Extremely high, fast surface searing |

| Speed | Quick, typically 5-10 minutes | Very fast, often under 5 minutes |

| Energy Efficiency | Moderate | High energy efficiency |

| Control Precision | Basic temperature control | Advanced temperature and intensity control |

| Common Usage | Home kitchens, grilling steaks | Professional kitchens, precise finishing |

Introduction to Broiling and Infrared Cooking

Broiling involves cooking food using high heat from an overhead source, typically in an oven, which quickly sears the surface of steaks to lock in juices. Infrared cooking utilizes radiant heat emitted by an infrared element, providing intense and even heat that penetrates the meat for fast, consistent finishing.

Broiling is widely favored for achieving a caramelized crust and marked grill lines on steaks. Infrared cooking offers precise temperature control and reduced cooking times, enhancing the texture and flavor while minimizing moisture loss.

How Broiling Works: Traditional Methods

Broiling uses high heat from an overhead source, typically an electric or gas heating element, to cook food quickly by direct radiant heat. This method requires positioning the steak close to the heat to achieve a caramelized crust while retaining juiciness inside.

Traditional broiling involves placing the steak on a broiler pan under the heating element in an oven, exposing it to intense heat from above. This technique allows for even surface searing and Maillard reaction, essential for flavor development. Temperature control and timing are critical to prevent overcooking or charring when finishing steaks.

The Science Behind Infrared Cooking

How does infrared cooking scientifically differ from broiling when finishing steaks? Infrared cooking uses electromagnetic radiation to directly heat the steak's surface, allowing for faster and more even searing without overheating the interior. This method enhances Maillard reactions, producing a flavorful crust while preserving juiciness better than traditional broiling techniques.

Heat Distribution: Broiler vs Infrared

Broiling uses high, direct heat from above to cook steaks quickly, often leading to uneven heat distribution due to variations in broiler element position and distance. Infrared cooking emits consistent, intense heat that penetrates the steak surface evenly, ensuring uniform cooking and caramelization.

Infrared broilers maintain a steady temperature, reducing hot spots and enhancing crust formation on steaks. Conventional broiling requires frequent monitoring to avoid overcooking areas exposed to fluctuating heat intensity.

Speed and Efficiency: Which Method Finishes Steaks Faster?

Infrared cooking finishes steaks faster than broiling due to its higher heat intensity and direct energy transfer. Broiling provides even cooking but generally requires more time to achieve the desired finish.

- Infrared Heat Intensity - Infrared emitters produce concentrated heat that sears steaks quickly, reducing cooking time.

- Energy Efficiency - Infrared technology converts most energy directly into heat, minimizing loss and speeding up the cooking process.

- Broiling Time Frame - Broiling uses radiant heat from the oven's top element, which heats steaks less intensely and takes longer to achieve a similar finish.

Crust Formation: Maillard Reaction Comparison

Broiling utilizes intense radiant heat from above to create a crispy crust through the Maillard reaction, whereas infrared cooking employs high-energy light waves that penetrate the steak surface for rapid browning. The Maillard reaction under broiling often results in uneven crust formation compared to the more consistent searing achieved with infrared heat.

- Broiling crust - forms primarily by direct radiant heat causing surface sugars and proteins to caramelize.

- Infrared crust - achieves faster, more uniform Maillard browning due to higher energy wavelength penetration.

- Heat distribution - broiling heat is less evenly distributed, often producing varied crust textures.

Infrared cooking offers superior crust quality and efficiency for finishing steaks compared to traditional broiling methods.

Flavor Differences: Broiling vs Infrared

Broiling imparts a more traditional, charred flavor by exposing the steak to direct radiant heat, while infrared cooking delivers a sear with intense, consistent heat that can enhance the Maillard reaction. Infrared's rapid surface caramelization preserves juiciness and creates a uniquely smoky aroma compared to the broader heat distribution of broiling.

- Broiling produces a classic char flavor - Uses radiant heat from above to create a crust with familiar grill-like taste.

- Infrared cooking intensifies caramelization - Delivers high, focused heat that boosts the Maillard reaction for enhanced flavor complexity.

- Juiciness retention differs - Infrared's quick searing helps lock in moisture better than the slower broiling method.

Precision and Control in Steak Finishing

| Broiling | Utilizes radiant heat from an overhead source, allowing for precise browning and controlled caramelization on steaks, ideal for achieving a crisp exterior without overcooking the interior. |

| Infrared Cooking | Delivers intense, focused heat with rapid temperature changes, offering enhanced temperature control and consistent results, but requires careful monitoring to prevent flare-ups and uneven cooking. |

| Precision and Control | Broiling provides a steady and adjustable heat source that fine-tunes the finish on steaks, while infrared cooking excels in speed and uniform heat distribution, necessitating skillful use to maintain precise control over doneness and texture. |

Equipment and Accessibility for Home Cooks

Broiling uses a conventional oven's heating element positioned close to the food, making it accessible and easy to use for home cooks without specialized equipment. Infrared cooking requires dedicated infrared broilers or grills that emit intense heat through infrared radiation, often involving higher upfront costs and less common availability in typical kitchens. Most home cooks benefit from broiling due to its simplicity and compatibility with standard ovens, while infrared cooking offers faster searing but demands investment in specific appliances.

Related Important Terms

Radiant Panel Broiling

Radiant panel broiling uses direct, intense heat to sear steaks quickly, creating a caramelized crust while locking in juices, compared to infrared cooking which emits higher-energy waves for faster heat transfer but may cause uneven cooking. The controlled heat distribution of radiant panel broiling ensures consistent finishing with precise temperature management, ideal for achieving optimal steak texture and flavor.

Quartz Element Infrared

Quartz element infrared broiling delivers intense, focused heat that sears steaks quickly, preserving juiciness and enhancing caramelization better than traditional broiling. The rapid infrared radiation penetrates the meat's surface efficiently, achieving a perfectly finished steak with fewer cooking times and less moisture loss.

Hybrid Grill Broilers

Hybrid grill broilers combine broiling's intense direct heat with infrared cooking's rapid, even temperature distribution, delivering perfectly seared steaks with enhanced caramelization and juiciness. This fusion technology optimizes finishing by reducing cooking time while preserving the steak's interior tenderness and robust flavor profile.

Direct Energy Searing

Broiling offers direct radiant heat from above, creating a high-temperature environment ideal for direct energy searing that rapidly caramelizes steak surfaces, locking in juices and enhancing flavor. Infrared cooking also uses intense radiant heat but delivers more consistent and even searing, reducing flare-ups while achieving a similar Maillard reaction for perfectly finished steaks.

Near-Infrared Caramelization

Broiling uses high heat from above to quickly sear steaks, while infrared cooking employs near-infrared radiation that penetrates the meat surface, enhancing Maillard reactions and creating superior caramelization. Near-infrared caramelization intensifies flavor development by promoting faster browning and improved crust formation compared to traditional broiling methods.

Flame Impingement Finish

Broiling delivers a flame impingement finish by exposing steaks to intense, direct radiant heat that quickly caramelizes the surface, creating a flavorful crust. Infrared cooking, while also providing high heat, typically offers more even heat distribution but lacks the same direct flame contact, which can result in a less pronounced char and smoky flavor.

Variable Heat Zoning

Broiling provides uneven, high-intensity heat primarily from above, which can cause inconsistent cooking zones on a steak's surface, whereas infrared cooking utilizes precise variable heat zoning to evenly distribute radiant heat, ensuring a uniformly caramelized crust. Variable heat zoning in infrared systems allows targeted temperature control, optimizing Maillard reaction development and reducing overcooked or undercooked spots common in traditional broiling.

Catalytic Infrared Sizzle

Catalytic Infrared Sizzle provides intense, focused heat that enhances the Maillard reaction, producing a superior crust and flavor compared to traditional broiling methods. Unlike conventional broilers, infrared cooking delivers rapid, even heat penetration that seals in juices while achieving a perfect steak finish with less flare-ups and smoke.

Ultra-High Temp Broil Zones

Ultra-high temp broil zones reach temperatures above 1,000degF, creating intense radiant heat that sears steaks quickly, locking in juices while developing a flavorful crust. Infrared cooking offers similar high heat but with more even energy distribution, though broiling maintains the advantage in speed and direct heat concentration for optimal steak finishing.

Broiling vs Infrared cooking for finishing steaks. Infographic

cookingdiff.com

cookingdiff.com