A metal baking sheet offers even heat distribution and is less prone to warping during broiling, making it a reliable choice for consistent cooking results. Carbon steel broilers heat up quickly and provide superior heat retention, allowing for faster searing and crisping of food. Choosing between the two depends on whether you prioritize durability and even heat or rapid temperature responsiveness for broiling pet dishes.

Table of Comparison

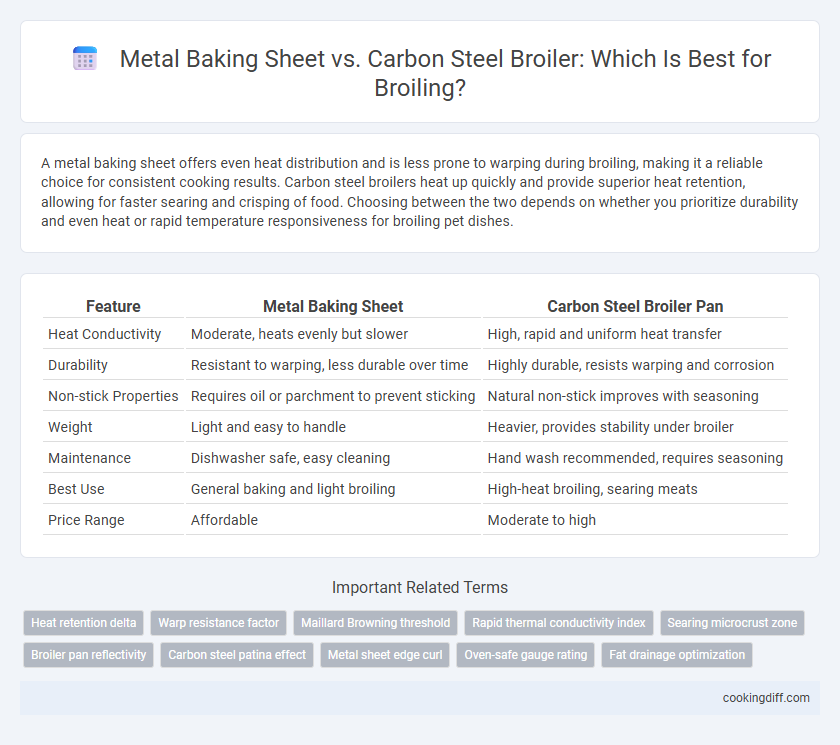

| Feature | Metal Baking Sheet | Carbon Steel Broiler Pan |

|---|---|---|

| Heat Conductivity | Moderate, heats evenly but slower | High, rapid and uniform heat transfer |

| Durability | Resistant to warping, less durable over time | Highly durable, resists warping and corrosion |

| Non-stick Properties | Requires oil or parchment to prevent sticking | Natural non-stick improves with seasoning |

| Weight | Light and easy to handle | Heavier, provides stability under broiler |

| Maintenance | Dishwasher safe, easy cleaning | Hand wash recommended, requires seasoning |

| Best Use | General baking and light broiling | High-heat broiling, searing meats |

| Price Range | Affordable | Moderate to high |

Metal Baking Sheet vs Carbon Steel Broiler: Key Differences

Metal baking sheets offer even heat distribution for consistent broiling results, while carbon steel broilers heat up faster and provide superior heat retention. Carbon steel's durability and resistance to warping make it ideal for high-temperature broiling compared to thinner metal baking sheets.

The non-stick properties of many metal baking sheets reduce food sticking, but carbon steel broilers develop natural seasoning that enhances flavor and improves over time. Choosing between the two depends on factors like heat responsiveness, maintenance, and desired cooking performance.

Heat Conductivity in Broiling: Metal Baking Sheet vs Carbon Steel

Metal baking sheets typically have moderate heat conductivity, which can lead to uneven cooking under a broiler. Carbon steel broilers, known for superior heat conduction, offer more consistent and rapid heating, enhancing broiling efficiency.

- Metal baking sheets - Provide average heat distribution but may cause hotspots due to lower conductivity.

- Carbon steel broilers - Exhibit excellent heat retention and quick heat transfer, ideal for broiling.

- Heat conductivity difference - Carbon steel's higher thermal conductivity results in faster and more uniform cooking compared to standard metal sheets.

Choosing carbon steel broilers improves broiling performance through enhanced heat conductivity and even heat distribution.

Durability Comparison: Metal Baking Sheet or Carbon Steel Broiler

| Material | Durability | Maintenance |

|---|---|---|

| Metal Baking Sheet (Aluminum or Stainless Steel) | Moderate durability with potential warping under high heat; prone to scratches over time | Requires regular cleaning to prevent corrosion; can be non-stick coated but coatings may degrade |

| Carbon Steel Broiler | High durability and excellent heat retention; resists warping and withstands intense broiling temperatures | Requires seasoning to maintain protective layer; rapid oxidation possible if not properly cared for |

Nonstick Properties and Food Release in Broiling

Metal baking sheets often feature nonstick coatings that improve food release during broiling, reducing the likelihood of sticking. Carbon steel broilers naturally develop a seasoned, nonstick surface over time, enhancing their performance with repeated use.

- Metal baking sheet nonstick coatings - These provide immediate food release but may degrade under high broiling temperatures.

- Carbon steel seasoning - Forms a durable, natural nonstick layer that improves with frequent broiling and proper maintenance.

- Food release efficiency - Carbon steel typically offers superior long-term release compared to coated metal sheets, especially at very high heat.

Cooking Performance and Browning Results

Metal baking sheets, typically aluminum or stainless steel, provide even heat distribution which results in consistent cooking performance during broiling. Carbon steel broilers heat up faster and retain heat better, producing superior browning and crispness on foods.

Carbon steel broilers excel at developing a deep Maillard reaction due to their higher heat retention and responsiveness, enhancing flavor and texture. Metal baking sheets may cool quicker, leading to less intense browning but are easier to clean and more durable for repeated use. Choosing between the two depends on the desired balance between rapid, intense browning and ease of maintenance when broiling.

Cleaning and Maintenance: Pros and Cons

Metal baking sheets typically feature a non-stick coating that simplifies cleaning by preventing food from adhering, though they may require gentle handling to avoid surface damage. Carbon steel broilers, while more durable and resistant to warping, can develop rust if not properly dried and seasoned after each use.

Cleaning a metal baking sheet often involves mild detergents and soft sponges to preserve the coating, which can wear off over time with abrasive scrubbing. Carbon steel broilers benefit from regular seasoning with oil, creating a natural non-stick layer that enhances longevity but demands consistent maintenance to prevent corrosion.

Weight and Ease of Handling for Broiling

Which is easier to handle for broiling, a metal baking sheet or a carbon steel broiler? Metal baking sheets are generally lighter, making them easier to maneuver in and out of the oven quickly. Carbon steel broilers, while heavier, provide a sturdier grip and more durable surface for high-heat cooking tasks.

Safety and Warping Issues Under High Heat

Metal baking sheets, typically made of aluminum, offer excellent heat conduction but may warp under the intense heat of broiling, compromising safety. Carbon steel broilers provide superior durability and resistance to warping due to their thicker gauge and high tensile strength, making them safer for prolonged high-heat exposure. Choosing carbon steel reduces the risk of bending or releasing harmful chemicals, ensuring safer cooking performance during broiling.

Cost Analysis: Which Broiler Option Is More Affordable?

Metal baking sheets generally cost less upfront, making them a budget-friendly option for broiling tasks. Carbon steel broilers, while initially more expensive, offer superior durability and heat conductivity, potentially reducing replacement frequency and energy costs over time. Evaluating long-term value, carbon steel may prove more economical for frequent broilers despite a higher initial investment.

Related Important Terms

Heat retention delta

Carbon steel broilers exhibit superior heat retention compared to metal baking sheets, maintaining higher and more consistent temperatures essential for effective broiling. This enhanced heat retention delta ensures faster searing and more even cooking, reducing the risk of temperature drops that can occur with thinner metal sheets.

Warp resistance factor

Carbon steel broilers offer superior warp resistance compared to metal baking sheets due to their higher tensile strength and better heat distribution, which minimizes deformation at extreme broiling temperatures. Metal baking sheets, often made from aluminum, tend to warp more easily under intense heat, reducing their effectiveness and lifespan during broiling tasks.

Maillard Browning threshold

Carbon steel broilers reach higher temperatures more rapidly than metal baking sheets, promoting the Maillard browning reaction by surpassing the 300degF threshold essential for optimal flavor development. Metal baking sheets often heat unevenly and may not consistently achieve the necessary surface temperature to trigger efficient Maillard browning during broiling.

Rapid thermal conductivity index

Carbon steel broilers exhibit a rapid thermal conductivity index, allowing for faster heat transfer and more even cooking when compared to metal baking sheets. This enhanced thermal response ensures precise temperature control and optimal browning during broiling.

Searing microcrust zone

Metal baking sheets provide even heat distribution that enhances the formation of a uniform searing microcrust zone, while carbon steel broilers excel in achieving higher surface temperatures that intensify the Maillard reaction for a more pronounced and flavorful crust. The thermal conductivity of carbon steel promotes rapid browning and a crisp texture, making it ideal for intense searing compared to the steadier heat retention of metal baking sheets.

Broiler pan reflectivity

Metal baking sheets, typically made of aluminum or stainless steel, have lower reflectivity compared to carbon steel broiler pans, resulting in less efficient heat reflection during broiling. Carbon steel broiler pans enhance cooking by reflecting more radiant heat onto the food, promoting faster, more even browning and searing.

Carbon steel patina effect

Carbon steel broilers develop a natural patina over time that enhances heat distribution and creates a non-stick surface, making them ideal for consistent, high-temperature broiling. Unlike metal baking sheets, which may heat unevenly, carbon steel's seasoned surface improves with use, delivering superior searing and browning results.

Metal sheet edge curl

Metal baking sheets often experience edge curl when exposed to the intense heat of broiling, which can cause warping and uneven cooking surfaces. Carbon steel broilers resist edge curl due to their superior heat conductivity and structural strength, ensuring consistent heat distribution and a flatter cooking surface during high-temperature broiling.

Oven-safe gauge rating

Metal baking sheets typically have an oven-safe gauge rating between 16 and 18, providing moderate heat conduction suitable for broiling, while carbon steel broilers usually feature a thicker gauge around 10 to 14, ensuring superior heat retention and even cooking under high temperatures. Choosing a carbon steel broiler with a higher gauge rating enhances durability and consistent browning, making it ideal for intense broiling applications compared to thinner metal baking sheets.

Metal baking sheet vs Carbon steel broiler for broiling. Infographic

cookingdiff.com

cookingdiff.com