Wire racks allow heat to circulate evenly around pet food, promoting thorough broiling with a crisp texture, while baking steel provides intense, consistent heat from below for faster cooking and a nice sear. Wire racks help drain excess fat away, making them ideal for healthier preparations, whereas baking steel retains heat efficiently and delivers high temperature that can enhance browning and flavor. Choosing between the two depends on whether even airflow or maximum heat transfer is desired for your pet's meal.

Table of Comparison

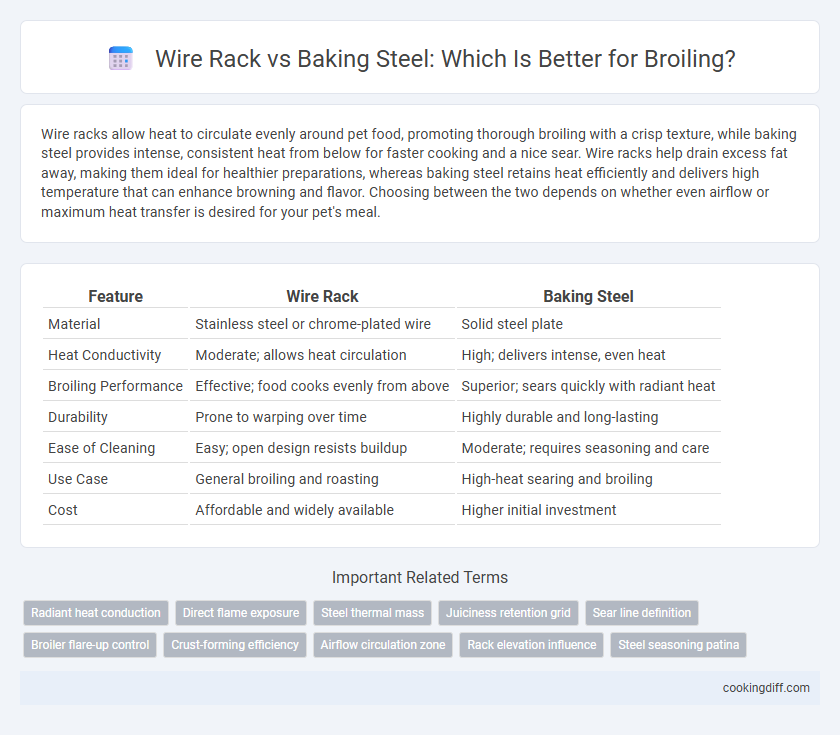

| Feature | Wire Rack | Baking Steel |

|---|---|---|

| Material | Stainless steel or chrome-plated wire | Solid steel plate |

| Heat Conductivity | Moderate; allows heat circulation | High; delivers intense, even heat |

| Broiling Performance | Effective; food cooks evenly from above | Superior; sears quickly with radiant heat |

| Durability | Prone to warping over time | Highly durable and long-lasting |

| Ease of Cleaning | Easy; open design resists buildup | Moderate; requires seasoning and care |

| Use Case | General broiling and roasting | High-heat searing and broiling |

| Cost | Affordable and widely available | Higher initial investment |

Introduction to Broiling: Methods and Tools

Broiling is a high-heat cooking method that uses direct radiant heat from an overhead source to quickly cook food. Choosing the right surface, such as a wire rack or baking steel, significantly impacts heat distribution and cooking results.

- Wire rack - Elevates food allowing fat and juices to drip away, promoting even exposure to heat and preventing steaming.

- Baking steel - Provides exceptional heat retention and conduction, delivering consistent, intense heat ideal for searing during broiling.

- Heat management - The choice between wire rack and baking steel affects browning, crispness, and overall texture of broiled foods.

What is a Wire Rack?

A wire rack is a kitchen tool made of metal grids that elevates food above the baking sheet, allowing heat to circulate evenly during broiling. It helps achieve a crisp texture by letting fat and juices drip away from the food.

Wire racks are typically constructed from stainless steel or chrome-plated steel, designed to withstand high broiling temperatures without warping. They promote airflow around the food, resulting in uniform cooking and browning. Unlike baking steel, wire racks do not store heat but provide consistent exposure to direct broiler heat.

Understanding Baking Steel for Broiling

Baking steel offers exceptional heat retention and even heat distribution, making it ideal for broiling meats and vegetables with a perfectly seared crust. Unlike wire racks, which allow fat to drip away but can cause uneven cooking, baking steel provides a solid, flat surface that promotes consistent browning and caramelization. Its high thermal conductivity ensures rapid recovery of temperature after opening the oven, enhancing broil performance compared to traditional broiling methods.

Heat Distribution: Wire Rack vs Baking Steel

Wire racks provide elevated airflow that promotes even heat circulation around the food, which helps achieve consistent browning during broiling. However, their thin metal construction can lead to heat loss, resulting in less intense, uneven heat on the food's surface.

Baking steel offers superior heat retention and distribution due to its dense, conductive material, producing a more uniform and higher temperature environment ideal for broiling. This consistent heat transfer enhances the crust formation and caramelization compared to wire racks.

Crispy Texture: Which Performs Better?

Wire racks promote even air circulation, allowing moisture to escape and helping foods develop a crispy texture when broiled. Baking steel provides intense, direct heat which can create a seared crust but may not offer the same airflow for optimal crispness.

- Wire Rack Airflow Advantage - Elevated design enables hot air to circulate around the food, reducing sogginess and enhancing crispiness.

- Baking Steel Heat Conductivity - High thermal mass delivers rapid, consistent heat ideal for searing but less effective in moisture dispersal.

- Texture Outcome Differences - Wire racks excel at drier, crispier finishes, while baking steel produces a robust sear with potentially less overall crispiness.

Choosing between wire racks and baking steel depends on whether airflow or direct heat better suits the desired crispy texture.

Broiling Time and Efficiency Comparison

Wire racks typically allow heat to circulate evenly around the food, reducing broiling time by promoting faster, more uniform cooking. Baking steel, with its superior thermal conductivity, stores and radiates intense heat, often cutting broiling time by several minutes compared to traditional wire racks.

Baking steel excels in efficiency by maintaining consistent high temperatures, which helps achieve quicker searing and browning during broiling. Wire racks may require longer preheating and produce less radiant heat, potentially extending total broiling time and reducing overall cooking efficiency.

Cleaning and Maintenance: Wire Rack vs Baking Steel

Wire racks are generally easier to clean since they can be removed and soaked, allowing grease and food particles to be scrubbed off with minimal effort. Baking steel requires more careful maintenance to prevent rust, often needing thorough drying and occasional seasoning after cleaning. Both tools benefit from immediate cleaning post-broiling, but wire racks demand less ongoing care compared to the seasoning process essential for baking steel longevity.

Versatility in Cooking Applications

Wire racks excel in versatility by allowing air circulation around food, making them perfect for broiling and roasting a variety of dishes. Baking steels provide consistent, intense heat ideal for broiling, baking, and even grilling, expanding their use beyond just broiling.

- Wire rack's open design - Promotes even cooking by allowing heat to surround the food.

- Baking steel's thermal mass - Retains high heat for searing and consistent broiling results.

- Multi-purpose usability - Baking steels serve as broiling surfaces, pizza stones, and grilling aids, offering broader versatility than wire racks.

Safety and Durability Considerations

Which option offers better safety and durability when broiling, wire rack or baking steel? Wire racks are designed with elevated grids that allow fat to drip away, reducing flare-ups and providing a safer broiling experience, though they may rust over time if not properly maintained. Baking steel provides exceptional durability thanks to its solid, rust-resistant surface, but requires careful handling due to its weight and heat retention to avoid burns or accidents.

Related Important Terms

Radiant heat conduction

Wire racks provide direct exposure to radiant heat, allowing broiled foods to cook evenly with crispy surfaces, while baking steels offer superior thermal conductivity, retaining and distributing intense radiant heat faster for more efficient searing and caramelization. The higher mass and density of baking steel enhance radiant heat transfer compared to the open structure of wire racks, resulting in more consistent browning and faster mouthwatering results.

Direct flame exposure

Wire racks provide better direct flame exposure during broiling, allowing food to cook quickly and develop a crisp exterior, while baking steels distribute heat more evenly but limit direct contact with flames, resulting in less intense charring. Choosing wire racks enhances the Maillard reaction through increased flame exposure, critical for achieving the characteristic broiled texture and flavor.

Steel thermal mass

Baking steel offers superior thermal mass compared to a wire rack, enabling more consistent and intense heat distribution essential for effective broiling. Its high thermal conductivity ensures rapid searing and even cooking, while the wire rack lacks sufficient mass to maintain stable temperatures under direct broiler heat.

Juiciness retention grid

Wire racks offer superior juiciness retention during broiling by allowing fat and juices to drip away, preventing food from sitting in its own rendered fats, while baking steel, being a solid surface, tends to trap these juices, potentially leading to less moisture retention and a drier result. The elevated grid structure of wire racks also promotes even heat circulation, enhancing caramelization without compromising the meat's internal moisture.

Sear line definition

Wire racks create distinct sear lines by allowing direct contact with the food and optimal air circulation, resulting in intense, even heat exposure. Baking steel provides a consistently hot, flat surface that promotes uniform searing but produces less pronounced sear lines compared to the elevated ridges of a wire rack.

Broiler flare-up control

Wire racks allow better airflow around food, reducing the risk of flare-ups by preventing fat from pooling, whereas baking steel, with its solid surface, can trap drippings and increase flare-up potential under the broiler. Choosing a wire rack over baking steel provides superior flare-up control and more even cooking during broiling.

Crust-forming efficiency

Wire racks provide better air circulation under the food, promoting even heat exposure and efficient crust formation, while baking steel offers superior heat retention and intense direct heat that can create a faster, more pronounced crust. Choosing between wire racks and baking steel depends on the desired crust texture, with wire racks favoring gentle browning and baking steel enabling rapid, caramelized crust development.

Airflow circulation zone

Wire racks enhance airflow circulation during broiling by allowing heat to surround the food evenly, promoting faster and more uniform cooking. Baking steel, while excellent for heat retention, limits airflow beneath the food, potentially resulting in less even browning compared to a wire rack.

Rack elevation influence

Wire racks offer adjustable elevation, allowing precise control over the distance between food and the broiler element, which enhances browning and prevents burning. Baking steel has a fixed height, providing consistent heat distribution but limiting elevation options that directly affect cooking intensity and timing.

Wire rack vs baking steel for broiling. Infographic

cookingdiff.com

cookingdiff.com