Candying fruit involves immersing it in a sugar syrup, which both preserves the fruit and enhances its sweetness, creating a chewy texture ideal for confections. Osmo-dehydration uses osmotic pressure by soaking fruit in concentrated solutions, reducing moisture content without fully cooking, thus retaining more of the natural fruit flavor and nutrients. While candying results in a longer shelf life and a distinct sugary taste, osmo-dehydration offers a healthier alternative by minimizing sugar uptake and preserving a more natural texture.

Table of Comparison

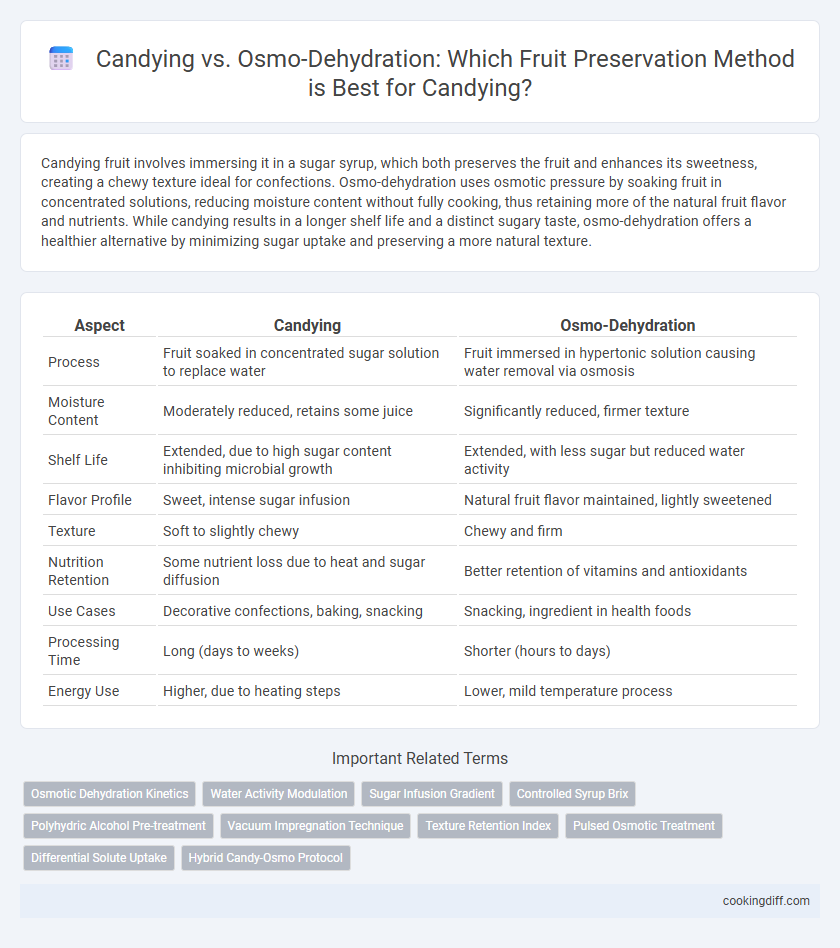

| Aspect | Candying | Osmo-Dehydration |

|---|---|---|

| Process | Fruit soaked in concentrated sugar solution to replace water | Fruit immersed in hypertonic solution causing water removal via osmosis |

| Moisture Content | Moderately reduced, retains some juice | Significantly reduced, firmer texture |

| Shelf Life | Extended, due to high sugar content inhibiting microbial growth | Extended, with less sugar but reduced water activity |

| Flavor Profile | Sweet, intense sugar infusion | Natural fruit flavor maintained, lightly sweetened |

| Texture | Soft to slightly chewy | Chewy and firm |

| Nutrition Retention | Some nutrient loss due to heat and sugar diffusion | Better retention of vitamins and antioxidants |

| Use Cases | Decorative confections, baking, snacking | Snacking, ingredient in health foods |

| Processing Time | Long (days to weeks) | Shorter (hours to days) |

| Energy Use | Higher, due to heating steps | Lower, mild temperature process |

Introduction to Fruit Preservation Techniques

Candying and osmo-dehydration are two popular fruit preservation techniques that enhance shelf life and flavor. Candying involves soaking fruit in sugar syrup, creating a sweet and glossy coating that inhibits microbial growth.

Osmo-dehydration uses osmotic pressure to draw out water from the fruit, concentrating sugars and preserving texture while reducing drying time. Both methods maintain fruit quality but differ in process, moisture retention, and final taste profile.

Understanding Candying: Process and Purpose

Candying is a fruit preservation method that involves soaking fruit in sugar syrup until it becomes saturated with sugar, effectively inhibiting microbial growth. This process enhances shelf life while maintaining the fruit's texture and color, distinguishing it from osmo-dehydration which relies on water removal via osmotic pressure.

- Sugar Saturation - Candying immerses fruit in concentrated sugar solutions to replace water content with sugar, preserving flavor and texture.

- Microbial Inhibition - The high sugar concentration in candied fruit creates an environment unsuitable for microbial activity, extending shelf stability.

- Comparison to Osmo-Dehydration - Unlike candying, osmo-dehydration primarily removes water by osmotic diffusion using lower-concentration solutions, leading to different textural and preservation outcomes.

Osmo-Dehydration Explained

Osmo-dehydration is a fruit preservation technique that involves immersing fruit in a hypertonic sugar solution to remove moisture through osmosis without heat. This method maintains the fruit's texture and natural flavor better than traditional candying, which typically involves cooking fruit in sugar syrup.

- Moisture Reduction - Osmo-dehydration reduces water content by osmosis, enhancing shelf life while retaining juiciness.

- Texture Preservation - Unlike candying, osmo-dehydration keeps fruit firmer and less sticky by avoiding high temperature exposure.

- Flavor Retention - The process preserves natural flavors by minimizing heat-induced flavor changes common in candying.

Osmo-dehydration offers a more natural and nutrient-friendly alternative for fruit preservation compared to traditional candying methods.

Key Differences Between Candying and Osmo-Dehydration

Candying involves soaking fruit in a concentrated sugar syrup, resulting in a sweetened, preserved product with a glossy appearance. Osmo-dehydration uses osmotic pressure to remove water from fruit by immersing it in a hypertonic solution, reducing moisture content without adding excessive sweetness.

Candying typically extends shelf life by increasing sugar concentration, which inhibits microbial growth, while osmo-dehydration lowers water activity to delay spoilage. The candying process alters texture to a firmer, chewier consistency, whereas osmo-dehydration preserves more of the fruit's natural texture and flavor.

Effects on Fruit Texture and Flavor

Candying preserves fruit by immersing it in concentrated sugar syrup, resulting in a firm, glossy texture with intensified sweetness and a rich, syrupy flavor. Osmo-dehydration reduces water content through osmotic pressure, maintaining a chewy texture and more natural fruit flavor with less sweetness. Candying typically produces a denser texture and more pronounced sweetness compared to the milder taste and flexible texture of osmo-dehydrated fruit.

Nutritional Impact of Both Methods

| Candying significantly increases sugar content, which may reduce the fruit's natural vitamins, especially vitamin C and B-complex. Osmo-dehydration preserves more antioxidants and retains higher levels of minerals due to lower heat exposure and reduced sugar infusion. Nutrient retention during osmo-dehydration is generally superior, making it a healthier choice for fruit preservation. |

Shelf Life and Storage Considerations

Candied fruits have an extended shelf life due to their high sugar content, which acts as a natural preservative inhibiting microbial growth. Osmo-dehydrated fruits retain more moisture, resulting in a shorter shelf life compared to traditional candying methods.

Storage for candied fruits requires cool, dry conditions to prevent sugar crystallization and spoilage, allowing them to last several months to a year. Osmo-dehydrated fruits need refrigeration or freezing for prolonged preservation, as their higher moisture content increases susceptibility to mold and enzymatic degradation. Both methods benefit from airtight packaging to maintain quality and prevent moisture absorption during storage.

Suitability for Different Fruit Types

Candying is highly suitable for fruits with firm textures like cherries, citrus peel, and ginger, as it preserves their shape and enhances sweetness through sugar infusion. Osmo-dehydration works well for delicate fruits such as berries and grapes, where maintaining nutritional value and natural flavor is essential without the intense sugary coating. Both methods offer tailored preservation benefits, with candying favoring texture retention in sturdier fruits and osmo-dehydration preserving softness and moisture in more fragile varieties.

Cost and Efficiency Comparison

Candying fruit typically requires higher energy input and longer processing times, leading to increased operational costs compared to osmo-dehydration. Osmo-dehydration offers greater efficiency by reducing water activity faster while consuming less sugar and energy.

- Candying is cost-intensive - It involves prolonged boiling and sugar syrup usage, increasing utility expenses.

- Osmo-dehydration is energy-efficient - The process operates at lower temperatures with less energy demand.

- Processing time differs significantly - Candying can take several hours versus the relatively quicker osmo-dehydration, enhancing throughput.

Related Important Terms

Osmotic Dehydration Kinetics

Osmotic dehydration kinetics involves the diffusion-driven removal of water from fruit tissue by immersing it in hypertonic sugar solutions, resulting in significant moisture loss and solute gain that effectively preserves the fruit while maintaining texture and color better than traditional candying methods. The rate of osmotic dehydration depends on factors such as solution concentration, temperature, fruit size, and structural properties, enabling precise control over dehydration extent and quality retention during fruit preservation.

Water Activity Modulation

Candying significantly reduces water activity by replacing fruit moisture with sugar, creating a stable environment that inhibits microbial growth and enzymatic reactions. Osmo-dehydration modulates water activity through partial solute infusion and moisture removal, preserving fruit texture and nutritional quality while extending shelf life.

Sugar Infusion Gradient

Candying creates a sugar infusion gradient by gradually replacing fruit moisture with concentrated sugar syrup, enhancing preservation and texture while maintaining flavor integrity. Osmo-dehydration induces osmotic pressure differences that draw out water but often result in a less uniform sugar distribution, affecting taste and shelf-life compared to the controlled infusion in candying.

Controlled Syrup Brix

Candying involves immersing fruit in sugar syrups with controlled high Brix levels, typically above 70deg, to achieve moisture reduction and sugar infusion that preserves texture and flavor. Osmo-dehydration uses lower Brix syrups, usually between 30deg and 60deg, enabling partial water removal while maintaining higher moisture content, resulting in a different texture and preservation profile.

Polyhydric Alcohol Pre-treatment

Polyhydric alcohol pre-treatment in candying enhances moisture retention and texture by reducing water activity, whereas in osmo-dehydration, it primarily facilitates osmotic balance and solute diffusion for effective dehydration. This pre-treatment optimizes fruit preservation by inhibiting microbial growth and enzymatic browning, improving shelf life and product quality.

Vacuum Impregnation Technique

Vacuum impregnation enhances osmo-dehydration by facilitating deeper and more uniform infusion of sugar solutions into fruit pores, improving texture and preservation compared to traditional candying methods. This technique reduces processing time and nutrient loss while maintaining fruit quality, making it a superior choice for fruit preservation.

Texture Retention Index

Candying achieves a higher Texture Retention Index compared to Osmo-Dehydration by infusing fruit with sugar syrup, which maintains cellular firmness and moisture balance. Osmo-Dehydration often results in softer textures due to lower sugar saturation and prolonged water loss, reducing firmness and chewiness in preserved fruit.

Pulsed Osmotic Treatment

Pulsed Osmotic Treatment enhances fruit preservation by combining repeated osmotic dehydration cycles with controlled rest intervals, improving solute diffusion and moisture removal compared to traditional candying. This method offers superior texture retention and reduced processing time over standard Osmo-Dehydration, achieving higher quality preserved fruits with balanced sweetness and minimal nutritional loss.

Differential Solute Uptake

Candying involves immersing fruit in highly concentrated sugar syrup, resulting in significant sugar infusion and moisture reduction, which enhances shelf-life and texture. Osmo-dehydration uses osmotic pressure differences to partially remove water and moderately infuse solutes, preserving nutrients with less sugar uptake compared to traditional candying.

Candying vs Osmo-Dehydration for fruit preservation. Infographic

cookingdiff.com

cookingdiff.com