Using a cast iron skillet for caramelizing pet treats offers superior heat retention and even cooking, resulting in a rich, consistent caramel layer. In contrast, an electric caramelizer provides precise temperature control and convenience, reducing the risk of burning but may lack the traditional depth of flavor achieved with cast iron. Choosing between the two depends on whether you prioritize artisanal texture or efficiency in your caramelizing process.

Table of Comparison

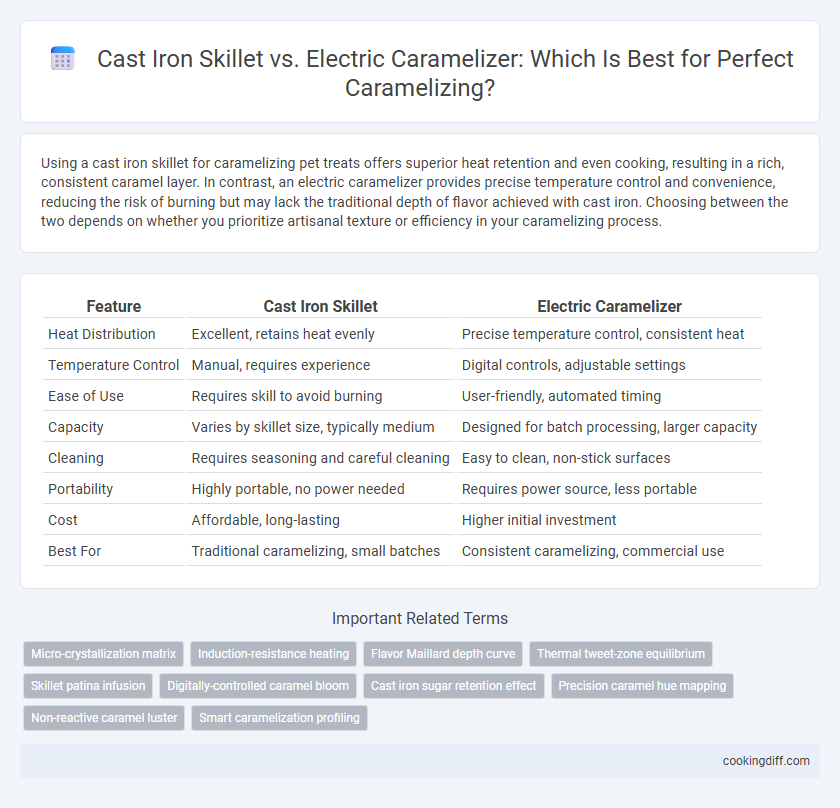

| Feature | Cast Iron Skillet | Electric Caramelizer |

|---|---|---|

| Heat Distribution | Excellent, retains heat evenly | Precise temperature control, consistent heat |

| Temperature Control | Manual, requires experience | Digital controls, adjustable settings |

| Ease of Use | Requires skill to avoid burning | User-friendly, automated timing |

| Capacity | Varies by skillet size, typically medium | Designed for batch processing, larger capacity |

| Cleaning | Requires seasoning and careful cleaning | Easy to clean, non-stick surfaces |

| Portability | Highly portable, no power needed | Requires power source, less portable |

| Cost | Affordable, long-lasting | Higher initial investment |

| Best For | Traditional caramelizing, small batches | Consistent caramelizing, commercial use |

Introduction to Caramelizing Techniques

Caramelizing is the process of slowly heating sugar or foods to develop rich, complex flavors and a deep golden color. Traditional cast iron skillets offer excellent heat retention and distribution, ideal for achieving even caramelization.

Electric caramelizers provide precise temperature control and consistent heat, reducing the risk of burning sugar. Both tools have unique advantages that cater to different caramelizing techniques and recipes.

Overview: Cast Iron Skillet vs Electric Caramelizer

Cast iron skillets provide even heat distribution essential for achieving perfect caramelization, offering a traditional stovetop method. Electric caramelizers deliver precise temperature control and consistent heat, ideal for replicating professional results efficiently.

- Cast iron skillet heat retention - Retains and distributes heat evenly, preventing hot spots for uniform caramelizing.

- Electric caramelizer temperature control - Features adjustable thermostats for consistent and accurate caramelization temperatures.

- Usage convenience - Cast iron requires manual heat adjustment, while electric caramelizers offer automated settings for ease of use.

Heat Distribution and Temperature Control

Cast iron skillets offer excellent heat retention and even heat distribution, making them ideal for slow, consistent caramelizing. Electric caramelizers provide precise temperature control with adjustable settings, reducing the risk of burning sugars. While cast iron requires manual temperature management, electric caramelizers ensure consistent results through digital regulation.

Flavor Development: Traditional vs Electric Methods

| Cast Iron Skillet: Offers superior heat retention and even distribution, allowing for deep Maillard reactions and richer, more complex caramel flavors essential for authentic caramelization. |

| Electric Caramelizer: Provides precise temperature control, reducing the risk of scorching but often results in less nuanced flavor development due to lower heat intensity and uneven heat application compared to cast iron. |

Ease of Use and Convenience

Which option offers greater ease of use for caramelizing, a cast iron skillet or an electric caramelizer? Cast iron skillets provide versatile control over heat but require constant attention to prevent burning. Electric caramelizers feature precise temperature settings and timers, enhancing convenience and reducing the risk of overcooking caramel.

Cleaning and Maintenance Requirements

Cast iron skillets require thorough cleaning and seasoning after caramelizing to prevent rust and maintain their non-stick surface. Residual sugars can cause stubborn buildup, necessitating careful scrubbing without harsh detergents to preserve the skillet's seasoning layer.

Electric caramelizers often feature non-stick surfaces that simplify cleaning but may degrade over time with frequent use and abrasive scrubbing. Their design usually allows for easier maintenance, although some components might need occasional disassembly for thorough cleaning to ensure optimal performance.

Suitability for Different Caramelizing Recipes

Cast iron skillets provide even heat distribution and excellent heat retention, making them ideal for caramelizing recipes that require slow, consistent cooking like caramel sauces and desserts. Electric caramelizers offer precise temperature control, which is beneficial for delicate recipes requiring exact heat levels, such as sugar art and candy making. Each tool suits different caramelizing needs: cast iron excels in versatility and depth of flavor, while electric caramelizers ensure accuracy and speed for professional or intricate caramel work.

Cost Comparison and Value

Cast iron skillets offer a one-time purchase cost with long-term durability, making them a cost-effective option for caramelizing at home. Electric caramelizers often have higher upfront costs but provide precise temperature control, which can improve consistency and reduce ingredient waste.

- Initial Cost - Cast iron skillets generally cost less upfront compared to electric caramelizers, which can be a significant investment.

- Durability and Longevity - Cast iron skillets are highly durable and can last decades, providing better long-term value for frequent users.

- Operational Efficiency - Electric caramelizers offer precise temperature settings that minimize caramelizing errors, potentially saving money on wasted ingredients over time.

Safety Considerations in Caramelizing

Using a cast iron skillet for caramelizing requires careful temperature control to prevent overheating and potential burns. Electric caramelizers offer consistent heat with automatic shut-off features, enhancing safety during the caramelization process.

- Heat distribution control - Cast iron skillets hold heat well but can cause hotspots, increasing burn risk.

- Automatic temperature regulation - Electric caramelizers regulate temperature precisely to avoid sugar burning.

- Handling precautions - Cast iron skillets become very hot and require proper gloves or handles for safe use.

Choosing the appropriate tool for caramelizing depends largely on balancing heat control and user safety requirements.

Related Important Terms

Micro-crystallization matrix

Cast iron skillets provide superior heat retention and even distribution essential for forming a stable micro-crystallization matrix in caramelizing, resulting in smoother and more consistent caramel textures. Electric caramelizers offer precise temperature controls but may produce uneven heat spots that disrupt the micro-crystallization process, affecting the final caramel quality.

Induction-resistance heating

Cast iron skillets offer superior heat retention and even distribution, making them ideal for caramelizing on induction-resistant heating surfaces, while electric caramelizers provide precise temperature control and consistent heat output. Induction resistance heating enhances the efficiency of cast iron skillets but electric caramelizers excel in maintaining stable caramelization temperatures for professional results.

Flavor Maillard depth curve

Cast iron skillets develop a superior Maillard reaction, producing deeper, richer caramelized flavors due to their even heat retention and high-temperature searing capabilities. Electric caramelizers offer precise temperature control but often lack the intense heat and flavor complexity achieved through the natural heat curve progression of cast iron.

Thermal tweet-zone equilibrium

Cast iron skillets maintain a superior thermal tweet-zone equilibrium due to their high heat retention and even heat distribution, allowing for consistent caramelization without hot spots. Electric caramelizers often struggle with temperature fluctuations and slower heat recovery, which can lead to uneven caramel development and increased risk of burning.

Skillet patina infusion

A cast iron skillet enhances caramelizing through its seasoned patina, which infuses rich, complex flavors as natural oils build up over time, creating a unique non-stick surface ideal for even browning. Electric caramelizers offer precise temperature control but lack the depth of flavor development and patina infusion inherent to cast iron skillets.

Digitally-controlled caramel bloom

Digitally-controlled caramel bloom in electric caramelizers offers precise temperature regulation, ensuring consistent caramelization without the risk of burning, unlike traditional cast iron skillets that require constant manual monitoring and adjustment. Electric caramelizers enhance repeatability and uniformity in caramel texture and color, optimizing efficiency for both professional and home kitchens.

Cast iron sugar retention effect

Cast iron skillets provide superior sugar retention during caramelizing due to their excellent heat retention and even heat distribution, which prevents sugar from crystallizing too quickly. This consistent temperature control allows for a smoother, richer caramel compared to electric caramelizers that may have fluctuating heat levels affecting sugar texture.

Precision caramel hue mapping

Cast iron skillets offer superior heat retention and even distribution, enabling precise caramel hue mapping through gradual temperature control. Electric caramelizers provide programmable settings for consistent caramelization but may lack the nuanced temperature modulation required for perfect caramel depth and color variation.

Non-reactive caramel luster

Cast iron skillets provide even heat distribution and excellent heat retention, preserving a rich, non-reactive caramel luster ideal for deep, complex caramelization without metallic taste interference. Electric caramelizers offer precise temperature control, ensuring consistent caramel development while maintaining a non-reactive surface that prevents color and flavor degradation during the process.

Cast iron skillet vs electric caramelizer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com