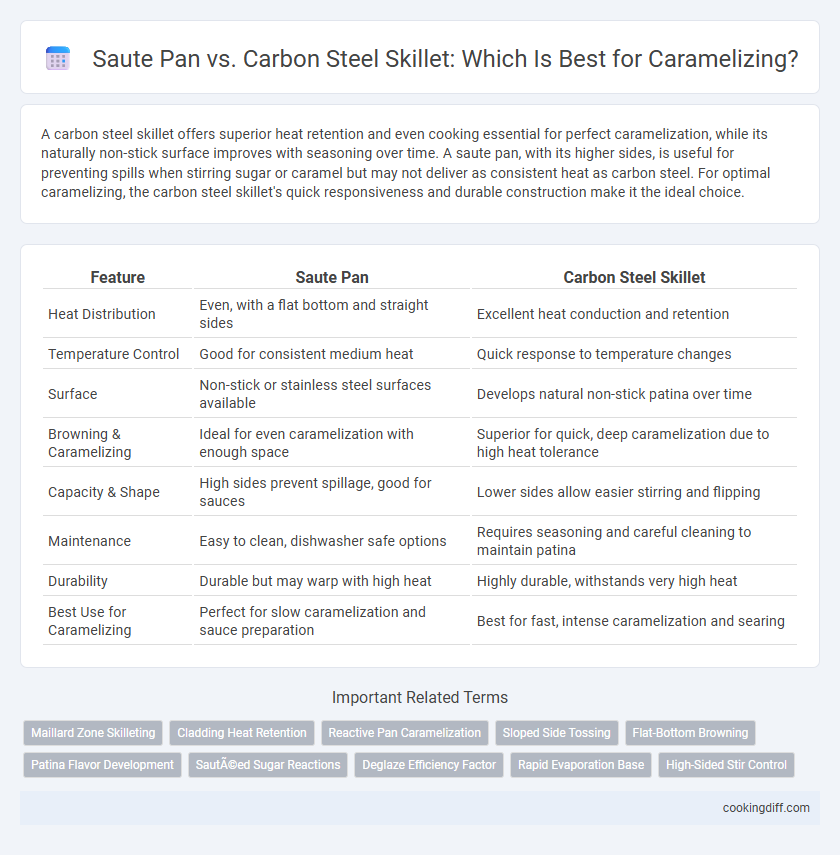

A carbon steel skillet offers superior heat retention and even cooking essential for perfect caramelization, while its naturally non-stick surface improves with seasoning over time. A saute pan, with its higher sides, is useful for preventing spills when stirring sugar or caramel but may not deliver as consistent heat as carbon steel. For optimal caramelizing, the carbon steel skillet's quick responsiveness and durable construction make it the ideal choice.

Table of Comparison

| Feature | Saute Pan | Carbon Steel Skillet |

|---|---|---|

| Heat Distribution | Even, with a flat bottom and straight sides | Excellent heat conduction and retention |

| Temperature Control | Good for consistent medium heat | Quick response to temperature changes |

| Surface | Non-stick or stainless steel surfaces available | Develops natural non-stick patina over time |

| Browning & Caramelizing | Ideal for even caramelization with enough space | Superior for quick, deep caramelization due to high heat tolerance |

| Capacity & Shape | High sides prevent spillage, good for sauces | Lower sides allow easier stirring and flipping |

| Maintenance | Easy to clean, dishwasher safe options | Requires seasoning and careful cleaning to maintain patina |

| Durability | Durable but may warp with high heat | Highly durable, withstands very high heat |

| Best Use for Caramelizing | Perfect for slow caramelization and sauce preparation | Best for fast, intense caramelization and searing |

Introduction to Caramelizing: Why Pan Choice Matters

| The choice between a saute pan and a carbon steel skillet significantly impacts caramelizing outcomes due to their heat retention and surface area properties. A carbon steel skillet excels in high heat conduction and quick temperature changes, promoting even browning necessary for perfect caramelization. In contrast, a saute pan's deeper sides and larger surface create more room for stirring and evaporation, affecting the texture and depth of caramelized ingredients. |

Overview: Sauté Pan vs Carbon Steel Skillet

A saute pan features higher, straight sides and a larger surface area, which helps contain ingredients and moisture during caramelization, resulting in evenly cooked sugars and enhanced flavor development. Carbon steel skillets heat quickly and offer excellent heat retention, allowing precise temperature control to achieve the perfect caramelized crust with minimal sticking.

While saute pans excel in handling larger quantities and preventing spills during deglazing, carbon steel skillets provide superior responsiveness and seasoning benefits for a naturally non-stick surface. Both tools are valuable for caramelizing, but choice depends on recipe size and desired technique precision.

Heat Distribution: Key Differences for Caramelizing

Heat distribution plays a crucial role in achieving perfect caramelization, with saute pans offering consistent, even heat across their wider surface. Carbon steel skillets, while quickly responsive to temperature changes, tend to have hot spots that require more skill to manage for uniform caramelizing.

- Saute Pan Consistency - Provides even heat distribution ideal for slow, controlled caramelization without burning.

- Carbon Steel Responsiveness - Heats up rapidly but may cause uneven caramelizing due to localized hot spots.

- Temperature Control - Saute pans maintain steady temperatures better, making them more forgiving for caramelizing delicate sugars.

Surface Area: Maximizing Caramelization Results

Carbon steel skillets typically offer a larger, flat cooking surface which maximizes contact with the food, enhancing the caramelization process. Saute pans feature higher sides that limit the surface area but are ideal for stirring and preventing spillage during caramelization.

- Carbon Steel Skillet Surface - Provides broad, flat space for even heat distribution and optimal caramelization results.

- Saute Pan Design - Higher sides reduce cooking surface area but help contain ingredients, maintaining heat and moisture.

- Caramelization Efficiency - Maximized surface contact in carbon steel skillets typically leads to more uniform and faster caramelization.

Pan Material: Impact on Sugar Browning

Carbon steel skillets heat quickly and evenly, providing excellent temperature control essential for consistent sugar caramelization. Their natural seasoning creates a non-stick surface, reducing the risk of sugar sticking and burning during the process.

Saute pans, typically made from stainless steel or aluminum, offer a wider surface area but may have uneven heat distribution affecting sugar browning. The thicker base of some saute pans can retain heat longer, which may cause caramel to burn if not carefully monitored.

Ease of Control: Managing Temperature and Hot Spots

A carbon steel skillet offers superior heat conductivity and responsiveness, allowing precise temperature control essential for even caramelization. Its natural seasoning reduces hot spots, providing consistent browning without burning sugar.

Saute pans, with their thicker bases, maintain steady heat but can develop uneven hot spots that complicate temperature management during caramelizing. Their higher sides can trap steam, preventing sugars from crisping properly. Carbon steel skillets allow quick adjustments on the stove, making them ideal for delicate caramelization processes.

Versatility: Which Pan Handles More Techniques?

Saute pans offer deeper sides and a larger surface area, making them ideal for deglazing and preparing sauces alongside caramelizing sugars. Carbon steel skillets provide superior heat conduction and responsiveness, perfect for high-temperature caramelization and quick sauteing. Versatility leans toward carbon steel skillets due to their ability to handle multiple cooking methods, from searing to caramelizing with precision.

Cleanup and Maintenance: Post-Caramelization Care

Cleanup after caramelizing is simpler with a saute pan due to its non-stick coating, which prevents sugar from sticking and burning. Carbon steel skillets require immediate soaking and gentle scrubbing to remove caramel residue without damaging the seasoning layer. Regular maintenance of a carbon steel skillet involves thorough drying and oiling to prevent rust, making it more labor-intensive than saute pans.

Expert Tips: Getting Perfect Caramelization with Each Pan

Achieving perfect caramelization depends significantly on the choice between a saute pan and a carbon steel skillet. Each pan offers distinct heat distribution and retention properties that impact the browning process.

- Saute pan provides even heat distribution - Its wider base and higher sides enable consistent caramelization without burning.

- Carbon steel skillet heats up quickly - Ideal for fast caramelization but requires careful temperature control to avoid scorching.

- Preheating is crucial for both pans - Ensures the surface is hot enough to initiate the Maillard reaction effectively.

Mastering these expert tips allows for flawless caramelization tailored to each pan's unique characteristics.

Related Important Terms

Maillard Zone Skilleting

A carbon steel skillet excels in the Maillard zone for caramelizing due to its superior heat retention and even temperature distribution, allowing sugars and proteins to brown evenly and develop complex flavors. In contrast, a saute pan's higher sides and thinner base may cause uneven heat and less efficient caramelization, making carbon steel the preferred choice for optimal browning techniques.

Cladding Heat Retention

A carbon steel skillet excels in heat retention and even cladding, providing consistent, high temperatures ideal for the gradual caramelization of sugars in onions or vegetables. In contrast, a saute pan with multi-ply cladding offers superior heat distribution but may lose heat more quickly, requiring closer temperature management to prevent uneven caramelization.

Reactive Pan Caramelization

Reactive pans like carbon steel skillets enhance caramelization by promoting Maillard reactions due to their ability to interact with food's natural acids, resulting in deeper, more complex flavors. Unlike non-reactive saute pans, carbon steel skillets develop a seasoned surface that improves heat distribution and creates optimal contact for even browning without burning.

Sloped Side Tossing

A carbon steel skillet's sloped sides facilitate effortless tossing and even heat distribution, making it ideal for caramelizing ingredients without overcrowding or uneven cooking. In contrast, a saute pan with higher, straighter sides restricts tossing motions, potentially leading to inconsistent caramelization and longer cooking times.

Flat-Bottom Browning

A carbon steel skillet offers superior heat retention and even flat-bottom browning, making it ideal for achieving consistent caramelization compared to a saute pan, which may have thinner construction and less surface contact with the heat source. The flat, wide surface of the carbon steel skillet ensures better Maillard reaction, promoting rich, uniform caramelized layers on ingredients.

Patina Flavor Development

A carbon steel skillet promotes superior patina formation over time, enhancing flavor complexity through its reactive surface that builds seasoning layers during caramelizing. Saute pans, often non-reactive and with thinner surfaces, lack this seasoning development, resulting in less depth of caramelized flavor.

Sautéed Sugar Reactions

A carbon steel skillet offers superior heat retention and even distribution, essential for achieving consistent Maillard reactions during caramelizing compared to a saute pan that may have thinner, less conductive materials. The skillet's ability to maintain steady high temperatures accelerates sugar browning and enhances complex flavor development in caramelization processes.

Deglaze Efficiency Factor

Carbon steel skillets offer a higher Deglaze Efficiency Factor due to their excellent heat conductivity and ability to create fond quickly, essential for rich caramelization flavors. Saute pans, though versatile, often have thicker bases that retain heat unevenly, reducing the efficiency of deglazing and the intensity of caramelized fond development.

Rapid Evaporation Base

A carbon steel skillet excels in caramelizing due to its rapid evaporation base that quickly disperses heat, preventing moisture buildup and allowing sugars to brown evenly. Saute pans typically have higher sides and slower evaporation, which can trap steam and inhibit the caramelization process.

Sauté pan vs carbon steel skillet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com