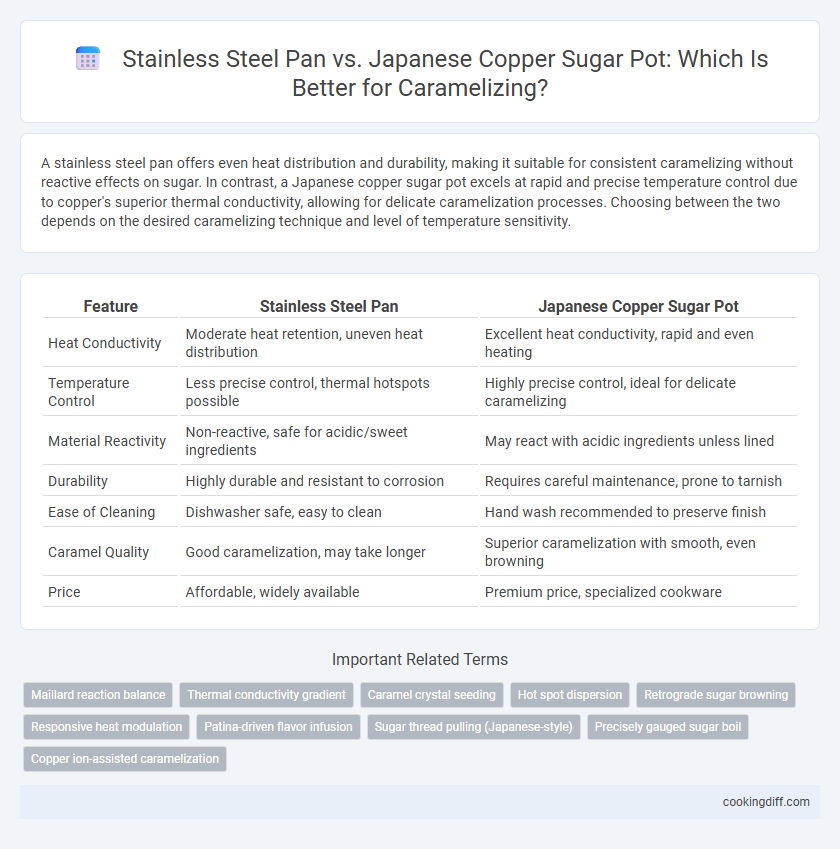

A stainless steel pan offers even heat distribution and durability, making it suitable for consistent caramelizing without reactive effects on sugar. In contrast, a Japanese copper sugar pot excels at rapid and precise temperature control due to copper's superior thermal conductivity, allowing for delicate caramelization processes. Choosing between the two depends on the desired caramelizing technique and level of temperature sensitivity.

Table of Comparison

| Feature | Stainless Steel Pan | Japanese Copper Sugar Pot |

|---|---|---|

| Heat Conductivity | Moderate heat retention, uneven heat distribution | Excellent heat conductivity, rapid and even heating |

| Temperature Control | Less precise control, thermal hotspots possible | Highly precise control, ideal for delicate caramelizing |

| Material Reactivity | Non-reactive, safe for acidic/sweet ingredients | May react with acidic ingredients unless lined |

| Durability | Highly durable and resistant to corrosion | Requires careful maintenance, prone to tarnish |

| Ease of Cleaning | Dishwasher safe, easy to clean | Hand wash recommended to preserve finish |

| Caramel Quality | Good caramelization, may take longer | Superior caramelization with smooth, even browning |

| Price | Affordable, widely available | Premium price, specialized cookware |

Introduction: Choosing the Best Pan for Caramelizing

Choosing the best pan for caramelizing impacts the texture and flavor of caramel significantly. Stainless steel pans and Japanese copper sugar pots each offer unique advantages for precise heat control during caramelization.

- Heat Conductivity - Japanese copper sugar pots provide superior and even heat distribution essential for consistent caramelization.

- Durability and Maintenance - Stainless steel pans are highly durable and easier to clean, making them practical for frequent use.

- Flavor Development - Copper's rapid temperature response allows more control over sugar's color and flavor in caramelizing processes.

Stainless Steel Pan Overview: Features and Benefits

What makes a stainless steel pan ideal for caramelizing sugar? Stainless steel pans offer excellent heat distribution and durability, ensuring even caramelization without hot spots. Their non-reactive surface prevents any metallic taste, preserving the pure flavor of caramel.

Japanese Copper Sugar Pot: Traditional Craftsmanship Explained

Japanese copper sugar pots, renowned for their exceptional heat conductivity, enable precise temperature control essential for perfect caramelization. Handcrafted using traditional techniques, these pots ensure even heat distribution, reducing the risk of burning sugar.

The copper material reacts quickly to temperature changes, allowing artisans to achieve the desired caramel texture and color with finesse. Unlike stainless steel pans, which heat unevenly, Japanese copper pots offer superior responsiveness, making them ideal for delicate sugar work.

Heat Conductivity: Stainless Steel vs Copper for Caramelization

Stainless steel pans have moderate heat conductivity, which allows for gradual and controlled caramelization but can result in uneven heating hotspots. Japanese copper sugar pots provide superior heat conductivity, distributing heat evenly and allowing precise temperature control critical for perfect caramelization.

Copper's high thermal conductivity rapidly responds to temperature changes, reducing the risk of burning sugar. This makes Japanese copper sugar pots ideal for delicate caramel work requiring consistent heat. In contrast, stainless steel may require more attentive heat management to avoid scorching during the caramelization process.

Temperature Control and Evenness

| Stainless Steel Pan | Offers moderate temperature control with a higher heat capacity, promoting steady caramelization. Heat distribution can be uneven, leading to hot spots that risk burning sugar if not carefully monitored. |

| Japanese Copper Sugar Pot | Provides superior temperature control due to excellent thermal conductivity, ensuring rapid heat adjustments. Even heat distribution minimizes the risk of scorching, resulting in smooth, consistent caramelization. |

Ease of Handling and Ergonomics

Stainless steel pans offer a balanced weight and sturdy handle, making them easier to maneuver during the caramelizing process. Japanese copper sugar pots, while excellent for heat conductivity, often feature lightweight construction and ergonomic handles designed for precision stirring.

- Weight Distribution - Stainless steel pans have a heavier base which provides stability but can be cumbersome for frequent stirring.

- Handle Design - Copper sugar pots typically have thinner, well-shaped handles that fit comfortably in hand for delicate control.

- Grip Comfort - Stainless steel handles usually feature a heat-resistant coating improving safety and grip during caramelizing.

Choosing between the two depends on balancing heat control with comfort during extended use.

Cleaning and Maintenance Comparison

Stainless steel pans offer easy cleaning and high resistance to corrosion, requiring only regular washing with warm soapy water to maintain their shine. Japanese copper sugar pots demand more delicate care, including hand washing and thorough drying to prevent tarnishing and maintain their heat conductivity. While stainless steel is low-maintenance, copper pots require polishing and careful handling to preserve their optimal caramelizing performance.

Flavor Impact: Does the Pan Material Matter?

Stainless steel pans distribute heat evenly but may cause caramel to cook faster, risking bitterness due to uneven temperature spots. Japanese copper sugar pots offer superior thermal conductivity, providing precise temperature control essential for achieving rich, balanced caramel flavors. The material of the pan directly influences the caramelization process, impacting the depth and complexity of the final taste.

Durability and Longevity of Cooking Vessels

Stainless steel pans are renowned for their exceptional durability, resisting corrosion and warping even under high heat, making them ideal for frequent caramelizing tasks. Their robust construction ensures long-lasting performance without compromising the cooking surface.

Japanese copper sugar pots offer superior heat conductivity, but their softer metal requires careful handling to prevent dents and tarnish, impacting longevity. Regular maintenance like polishing is necessary to preserve the pot's quality and extend its usability over time.

Related Important Terms

Maillard reaction balance

Stainless steel pans provide even heat distribution and high-temperature stability essential for precise control of the Maillard reaction during caramelizing, preventing uneven browning and burnt spots. Japanese copper sugar pots excel in rapid heat transfer and delicate temperature responsiveness, enabling a balanced Maillard reaction that yields a smooth, rich caramel flavor without scorching.

Thermal conductivity gradient

The Japanese copper sugar pot offers superior thermal conductivity with rapid, even heat distribution crucial for precise caramelizing, minimizing hot spots and preventing sugar burning. In contrast, stainless steel pans have lower thermal conductivity and slower heat response, leading to uneven caramelization and increased risk of scorching.

Caramel crystal seeding

A Japanese copper sugar pot offers superior heat conductivity and precise temperature control, crucial for uniform caramel crystal seeding compared to a stainless steel pan, which tends to have uneven heat distribution that can cause premature crystallization. The copper pot's rapid response to temperature changes reduces the risk of sugar grain formation, ensuring a smoother, more consistent caramel texture.

Hot spot dispersion

Japanese copper sugar pots offer superior hot spot dispersion compared to stainless steel pans, enabling more even caramelization and reducing the risk of burning sugars. Copper's excellent thermal conductivity ensures precise temperature control, crucial for achieving a smooth, consistent caramel texture.

Retrograde sugar browning

Stainless steel pans provide even heat distribution suitable for consistent caramelization but may cause uneven retrograde sugar browning due to rapid temperature changes. Japanese copper sugar pots offer superior heat conductivity and precise temperature control, minimizing retrograde browning and producing a smoother, more uniform caramel.

Responsive heat modulation

Japanese copper sugar pots offer superior responsive heat modulation compared to stainless steel pans, allowing precise temperature control essential for perfect caramelization. Copper's excellent thermal conductivity prevents hot spots and ensures even heat distribution, reducing the risk of burning sugar during the cooking process.

Patina-driven flavor infusion

A Japanese copper sugar pot enhances caramelizing through its rapidly developing patina, which infuses complex, nuanced flavors into sugar mixtures, while a stainless steel pan offers a neutral surface that ensures even heat distribution but lacks the flavor depth provided by copper's seasoned layers. The copper pot's unique reactive properties accelerate the formation of a flavorful patina, creating a richer caramel profile compared to stainless steel's inert cooking surface.

Sugar thread pulling (Japanese-style)

Japanese copper sugar pots offer superior heat conductivity and precise temperature control essential for achieving the delicate sugar thread pulling technique in caramelizing, compared to stainless steel pans which tend to distribute heat less evenly and may cause inconsistent caramel texture. The copper pot's ability to maintain a stable, high temperature allows for the perfect formation of thin, elastic sugar threads vital in traditional Japanese caramel work.

Precisely gauged sugar boil

A Japanese copper sugar pot offers superior heat conductivity and precise temperature control, essential for accurately gauging the sugar boil during caramelizing, which prevents scorching and ensures consistent caramel texture. In contrast, a stainless steel pan's slower and less even heat distribution can result in uneven caramelization and increased risk of burning sugar.

Stainless steel pan vs Japanese copper sugar pot for caramelizing. Infographic

cookingdiff.com

cookingdiff.com