Traditional stoves rely on direct flame or electric coils, providing uneven heat distribution that can cause inconsistent caramelization and increase the risk of burning sugar. Infrared burners offer precise, consistent heat, allowing for better control over caramelization temperatures and ensuring a smooth, even caramel layer. Using infrared technology enhances the caramelizing process by reducing hotspots and delivering efficient energy transfer for perfect results.

Table of Comparison

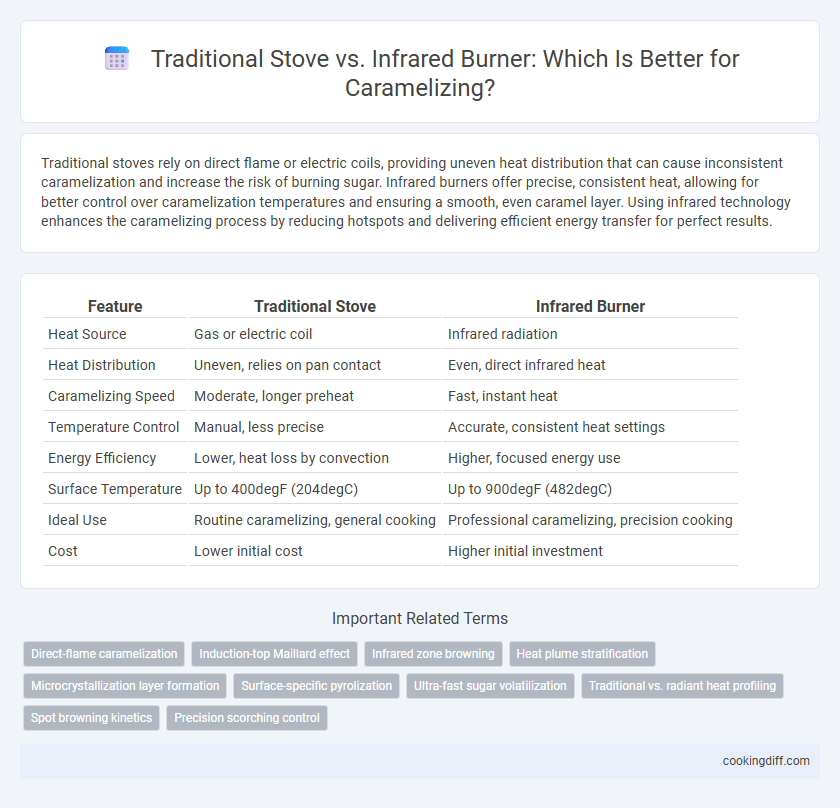

| Feature | Traditional Stove | Infrared Burner |

|---|---|---|

| Heat Source | Gas or electric coil | Infrared radiation |

| Heat Distribution | Uneven, relies on pan contact | Even, direct infrared heat |

| Caramelizing Speed | Moderate, longer preheat | Fast, instant heat |

| Temperature Control | Manual, less precise | Accurate, consistent heat settings |

| Energy Efficiency | Lower, heat loss by convection | Higher, focused energy use |

| Surface Temperature | Up to 400degF (204degC) | Up to 900degF (482degC) |

| Ideal Use | Routine caramelizing, general cooking | Professional caramelizing, precision cooking |

| Cost | Lower initial cost | Higher initial investment |

Introduction: Caramelizing Techniques Compared

Traditional stoves use direct heat through gas or electric coils, allowing precise control over caramelizing sugar and achieving rich flavors. Infrared burners emit radiant heat that penetrates food quickly, offering consistent caramelization with reduced risk of burning. Comparing both, traditional stoves provide tactile temperature adjustment while infrared burners ensure even heat distribution for optimal caramel texture.

Understanding Caramelization in Cooking

Traditional stoves use direct flame or electric coil to provide consistent, controllable heat essential for effective caramelization of sugars. Infrared burners deliver intense, radiant heat, allowing faster surface caramelization with precise temperature control.

Understanding caramelization requires recognizing the Maillard reaction temperatures, usually between 320degF and 350degF, which both heat sources can achieve. The choice between traditional stoves and infrared burners influences flavor depth, browning uniformity, and cooking speed during caramelization in culinary applications.

Traditional Stove: How It Works for Caramelizing

Traditional stoves use direct flame or electric coils to generate consistent, adjustable heat essential for caramelizing sugars evenly. The gradual temperature increase helps control the Maillard reaction, resulting in rich, deep caramel flavors and a smooth texture. Skilled cooks can manipulate heat levels precisely, ensuring the sugar melts without burning, which is crucial for perfect caramelization.

Infrared Burner: Modern Approach to Caramelizing

How does an infrared burner enhance the caramelizing process compared to traditional stoves? Infrared burners provide precise, even heat distribution, ensuring consistent caramelization without burning. This modern technology also heats up faster and maintains stable temperatures, improving efficiency and flavor development in cooking.

Heat Control and Precision: Stove vs. Infrared Burner

Traditional stoves provide steady heat but often lack the precise temperature control required for perfect caramelization, leading to uneven browning or burning. Infrared burners deliver focused, consistent heat that allows for more accurate temperature adjustments, enhancing caramelization quality.

Stove heat can fluctuate, making it challenging to achieve the ideal caramelization temperature, typically between 320degF and 350degF. Infrared burners reach targeted temperatures quickly and maintain them, ensuring precise control over the caramelizing process.

Flavor Development: Differences Between Methods

Traditional stove caramelizing relies on direct contact heat, allowing more gradual flavor development and deep Maillard reactions that enhance complexity. Infrared burners, emitting high-intensity, radiant heat, accelerate caramelization but may produce a less nuanced flavor profile due to rapid surface browning.

Flavor development with a traditional stove unfolds through steady heat transfer, promoting even sugar melting and a rich, layered taste. Infrared burners create intense heat zones that can quickly caramelize sugars, potentially leading to uneven caramelization and slightly bitter notes. Choosing between methods depends on balancing speed with the desired depth of caramel flavor in culinary applications.

Time Efficiency: Which Method is Faster?

| Method | Time Efficiency | Explanation |

|---|---|---|

| Traditional Stove | Moderate | Heats gradually, requiring 5-7 minutes to caramelize sugar evenly due to slower temperature rise and inconsistent heat distribution. |

| Infrared Burner | Fast | Reaches high temperatures rapidly within 2-3 minutes, enabling quicker caramelization and more precise temperature control for reduced cooking times. |

Safety Considerations: Comparing Both Methods

Traditional stoves often pose higher fire risks when caramelizing due to open flames and uneven heat distribution. Infrared burners offer more controlled heating, reducing the chances of burns and flare-ups during caramelization.

- Open Flame Hazard - Traditional stoves expose users to flames that can cause accidental fires or burns while caramelizing sugar.

- Temperature Control - Infrared burners provide precise, even heat that minimizes scorching and overheating risks.

- Surface Safety - Infrared cooktops remain cooler around the burner, reducing accidental contact burns compared to hot stove grates.

Best Caramelizing Practices for Each Heat Source

Traditional stoves provide direct, adjustable flame ideal for controlled caramelization, while infrared burners offer consistent, even heat distribution that minimizes hot spots. Each heat source demands specific techniques to optimize sugar browning and prevent burning during caramelizing.

- Traditional stove offers rapid heat control - Allows for quick temperature adjustments to manage the caramelization stages precisely.

- Infrared burner ensures uniform heating - Delivers steady, concentrated heat, reducing the risk of uneven caramelization.

- Use low to medium heat on traditional stoves - Prevents burning by slowly developing complex caramel flavors.

Maintaining vigilance and adjusting heat appropriately based on the burner type is key for perfect caramelization every time.

Related Important Terms

Direct-flame caramelization

Traditional stove caramelizes sugar through direct flame, producing uneven heat distribution that can cause localized burning and inconsistent caramel color. Infrared burners offer precise, uniform heat control for direct-flame caramelization, resulting in evenly browned caramel with enhanced flavor development and reduced risk of scorching.

Induction-top Maillard effect

Traditional stoves often rely on direct flame or electric coil heat that provides uneven temperature control, while infrared burners deliver consistent, radiant heat ideal for precise caramelizing and maximizing the Maillard effect on induction tops. Infrared technology enhances surface browning by promoting uniform heat distribution, accelerating sugar caramelization and flavor development for superior culinary results.

Infrared zone browning

Infrared burners provide precise and intense heat ideal for caramelizing by enabling rapid and uniform browning through radiant energy, significantly reducing cooking time compared to traditional stoves. The focused heat of infrared zones ensures consistent caramelization with minimal risk of burning, enhancing flavor development and texture in culinary applications.

Heat plume stratification

Traditional stoves produce uneven heat distribution with significant heat plume stratification, causing inconsistent caramelization and hotspots. Infrared burners deliver more uniform radiant heat that minimizes heat plume stratification, resulting in consistent browning and enhanced caramel flavor development.

Microcrystallization layer formation

Traditional stoves provide uneven heat distribution that can hinder the consistent microcrystallization layer formation essential for perfect caramelizing, whereas infrared burners deliver precise, uniform heat that enhances the development of a smooth, stable caramel layer. Infrared technology efficiently controls temperature fluctuations, promoting optimal sugar crystallization and a superior caramelized texture compared to conventional stovetop methods.

Surface-specific pyrolization

Traditional stove burners rely on direct flame and convective heat transfer, resulting in uneven surface temperatures that limit precise caramelization control. Infrared burners provide consistent, radiant heat leading to uniform surface-specific pyrolysis, enhancing caramelization quality by minimizing hotspots and ensuring optimal sugar browning.

Ultra-fast sugar volatilization

Infrared burners enable ultra-fast sugar volatilization during caramelizing by delivering intense, focused heat directly to the sugar, minimizing the risk of burning compared to traditional stoves. Traditional stoves use slower, indirect heat transfer, resulting in uneven caramelization and longer cooking times.

Traditional vs. radiant heat profiling

Traditional stoves use convection and conduction heat, offering uneven temperature distribution that can cause inconsistent caramelization due to hot spots and slower heat response. Infrared burners emit radiant heat that deeply penetrates the food surface, enabling rapid and uniform caramelization with precise temperature control and reduced risk of burning.

Spot browning kinetics

Spot browning kinetics differ significantly between traditional stoves and infrared burners during caramelizing, with infrared burners providing more uniform and rapid heat distribution that accelerates Maillard reactions and sugar caramelization. This enhances control over browning intensity and reduces hotspots, leading to more consistent caramelized surfaces compared to the uneven heating often observed with traditional gas or electric stoves.

Traditional stove vs Infrared burner for caramelizing. Infographic

cookingdiff.com

cookingdiff.com