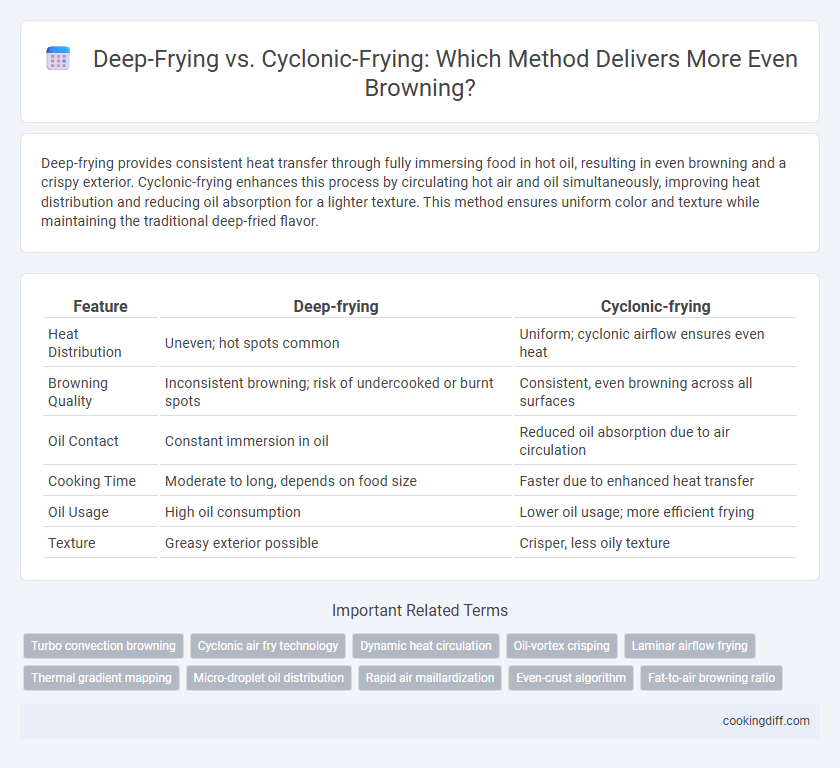

Deep-frying provides consistent heat transfer through fully immersing food in hot oil, resulting in even browning and a crispy exterior. Cyclonic-frying enhances this process by circulating hot air and oil simultaneously, improving heat distribution and reducing oil absorption for a lighter texture. This method ensures uniform color and texture while maintaining the traditional deep-fried flavor.

Table of Comparison

| Feature | Deep-frying | Cyclonic-frying |

|---|---|---|

| Heat Distribution | Uneven; hot spots common | Uniform; cyclonic airflow ensures even heat |

| Browning Quality | Inconsistent browning; risk of undercooked or burnt spots | Consistent, even browning across all surfaces |

| Oil Contact | Constant immersion in oil | Reduced oil absorption due to air circulation |

| Cooking Time | Moderate to long, depends on food size | Faster due to enhanced heat transfer |

| Oil Usage | High oil consumption | Lower oil usage; more efficient frying |

| Texture | Greasy exterior possible | Crisper, less oily texture |

Understanding Deep-Frying: Traditional Techniques for Even Browning

Deep-frying relies on submerging food in hot oil, typically between 350degF and 375degF, to achieve an even, golden-brown crust through Maillard reaction. Controlling oil temperature and ensuring uniform oil circulation are critical to prevent uneven browning and maintain crisp texture.

Cyclonic-frying enhances traditional deep-frying by using a high-speed oil vortex, promoting consistent heat distribution and reducing oil absorption. This technique improves even browning by minimizing hot spots and ensuring all surfaces of the food contact the heated oil uniformly.

What is Cyclonic-Frying? Modern Methods Explained

Cyclonic-frying is a modern cooking technique that circulates hot oil rapidly around food to achieve even browning and crispiness. Unlike traditional deep-frying, which submerges food in static oil, cyclonic-frying uses continuous oil movement to prevent uneven cooking and reduce oil absorption. This method enhances texture and flavor consistency, making it a popular choice in commercial kitchens.

Heat Distribution: Deep-Frying vs Cyclonic-Frying

Deep-frying relies on direct submersion of food in hot oil, providing uniform heat distribution through convection, which results in consistent even browning. Cyclonic-frying uses rapidly circulating hot air mixed with a small amount of oil, promoting faster heat transfer and less oil absorption but can produce slightly uneven browning compared to traditional deep-frying.

Heat distribution in deep-frying ensures thorough cooking by surrounding the food with heated oil that rapidly transfers heat. Cyclonic-frying's hot air flow creates an environment where heat is circulated rapidly, but the absence of full oil immersion can lead to hotspots and less consistent browning patterns. Choosing between both methods depends on the desired texture, oil usage, and evenness of color on the finished product.

Oil Usage: Comparing Deep-Frying and Cyclonic-Frying

Deep-frying typically requires a large volume of oil to fully submerge food, leading to higher oil consumption. Cyclonic-frying uses powerful air circulation combined with minimal oil, resulting in significantly lower oil usage while still achieving even browning.

- Deep-frying Oil Usage - Requires 3 to 5 liters of oil per batch, which increases operating costs and waste.

- Cyclonic-frying Oil Efficiency - Utilizes less than 10% of the oil volume used in deep-frying by coating food with fine oil mist.

- Environmental Impact - Cyclonic-frying reduces oil disposal needs and lowers the carbon footprint of frying operations.

Texture and Browning Consistency

| Cooking Method | Texture | Browning Consistency |

|---|---|---|

| Deep-frying | Produces a crispy exterior with a tender interior by submerging food in hot oil, promoting rapid heat transfer. | Can result in uneven browning due to oil temperature fluctuations and food placement, causing texture variability. |

| Cyclonic-frying | Ensures uniform crispiness with balanced moisture retention through continuously circulating hot air and oil mixture. | Delivers consistent and even browning across the food surface by maintaining steady heat distribution and airflow. |

Flavor Differences in Deep-Fried vs Cyclonic-Fried Foods

Deep-frying imparts a rich, intense flavor due to oil absorption and Maillard reactions, creating a crispy, golden exterior. Cyclonic-frying uses rapid airflow to circulate hot oil droplets, resulting in a lighter, less greasy taste with a more uniform browning.

- Deep-frying flavor profile - Deep-fried foods develop complex, savory notes from prolonged contact with hot oil.

- Cyclonic-frying flavor nuances - Cyclonic-fried foods maintain more natural ingredient flavors while achieving crisp texture.

- Maillard reaction impact - The Maillard reaction is more pronounced in deep-frying, enhancing caramelized and roasted flavors.

The choice between deep-frying and cyclonic-frying affects flavor intensity and textural crispness, balancing indulgence with lighter tastes.

Health Implications: Deep-Frying versus Cyclonic-Frying

Deep-frying typically involves submerging food in hot oil, which can lead to higher oil absorption and increased trans fat formation, negatively impacting cardiovascular health. Cyclonic-frying uses rapid air circulation with minimal oil, promoting even browning while reducing fat content and oxidative damage to oils.

- Deep-frying increases oil absorption - Foods absorb more oil during deep-frying, contributing to higher calorie intake and potential weight gain.

- Cyclonic-frying minimizes fat content - The technology uses less oil and circulates hot air to achieve crispiness, resulting in healthier food options.

- Oxidative stability differs - Cyclonic-frying reduces oil degradation and harmful oxidation products compared to traditional deep-frying methods.

Energy Efficiency and Cooking Times

How does deep-frying compare to cyclonic-frying in terms of energy efficiency and cooking times? Deep-frying typically consumes more energy due to prolonged heating of large oil volumes, whereas cyclonic-frying uses continuous hot air circulation, reducing energy use. Cyclonic-frying also shortens cooking times by promoting faster heat transfer and more even browning across food surfaces.

Maintenance and Clean-up: Which Method is Easier?

Deep-frying requires regular oil filtration and replacement to maintain cleanliness, making maintenance time-consuming and messy due to oil splatters. Cyclonic-frying systems are designed with self-cleaning features and enclosed frying chambers, which significantly reduce oil contamination and simplify clean-up procedures.

Cleaning deep-fryers involves dismantling parts for thorough washing, often resulting in greasy residues that demand extensive scrubbing. Cyclonic-frying minimizes residue buildup with controlled airflow, enabling quicker and more efficient maintenance, enhancing kitchen hygiene and operational uptime.

Related Important Terms

Turbo convection browning

Turbo convection browning in cyclonic-frying circulates hot air rapidly around the food, ensuring more even heat distribution and uniform browning compared to traditional deep-frying, which relies solely on oil immersion. This method reduces oil absorption and promotes a crispier texture by maintaining consistent surface temperatures, enhancing flavor and visual appeal.

Cyclonic air fry technology

Cyclonic air fry technology utilizes high-speed, swirling hot air to achieve even browning and crispiness by circulating heat uniformly around the food, reducing the risk of uneven cooking common in traditional deep-frying. This method significantly minimizes oil usage while enhancing texture and color consistency, making it a healthier and more efficient alternative for even frying results.

Dynamic heat circulation

Deep-frying utilizes static oil heat, often resulting in uneven browning due to localized hot spots, whereas cyclonic-frying employs dynamic heat circulation that continuously moves hot air and oil around the food, promoting uniform temperature distribution. This advanced heat movement in cyclonic-frying enhances even browning by reducing oil absorption and ensuring consistent crispness across the entire surface.

Oil-vortex crisping

Oil-vortex crisping in cyclonic-frying creates a dynamic, swirling hot oil environment that ensures more uniform heat distribution and consistent even browning compared to traditional deep-frying methods. This enhanced oil circulation reduces hotspots and promotes faster, crisper textures by thoroughly enveloping food surfaces.

Laminar airflow frying

Laminar airflow frying ensures consistent heat distribution and uniform oil contact, resulting in evenly browned surfaces compared to traditional deep-frying methods. Cyclonic-frying's turbulent air disrupts this smooth flow, often causing uneven browning and inconsistent texture on fried foods.

Thermal gradient mapping

Thermal gradient mapping reveals that cyclonic-frying provides a more uniform heat distribution across the food surface compared to traditional deep-frying, resulting in consistently even browning and reduced hotspots. This enhanced thermal uniformity minimizes oil absorption and improves texture by maintaining optimal frying temperatures throughout the cooking process.

Micro-droplet oil distribution

Deep-frying achieves even browning through consistent micro-droplet oil distribution that ensures uniform heat transfer across the food surface. Cyclonic-frying enhances this process by utilizing high-velocity air currents to disperse micro-droplets more evenly, resulting in superior browning and crispiness compared to traditional methods.

Rapid air maillardization

Deep-frying achieves even browning through rapid air Maillardization by immersing food in hot oil, which accelerates heat transfer and promotes uniform crust formation. Cyclonic-frying enhances this process by circulating hot air at high speeds, allowing faster moisture evaporation and more consistent Maillard reactions on food surfaces.

Even-crust algorithm

The Even-crust algorithm leverages precise temperature control and rapid hot-air circulation to ensure uniform heat distribution, resulting in consistent browning during cyclonic-frying compared to traditional deep-frying. This technology minimizes oil saturation and enhances crust texture by dynamically adjusting frying parameters for optimal surface crispness.

Deep-frying vs cyclonic-frying for even browning. Infographic

cookingdiff.com

cookingdiff.com