Deep-frying exposes food to high temperatures and atmospheric pressure, which can lead to significant nutrient loss and the formation of harmful compounds, whereas vacuum-frying occurs under reduced pressure, allowing frying at lower temperatures that better preserve nutrients, color, and texture. Vacuum-frying minimizes oxidation and moisture loss, resulting in products with enhanced shelf life and improved sensory qualities compared to traditional deep-frying. Selecting vacuum-frying over deep-frying is especially beneficial for preserving heat-sensitive vitamins and natural flavors in fruits and vegetables.

Table of Comparison

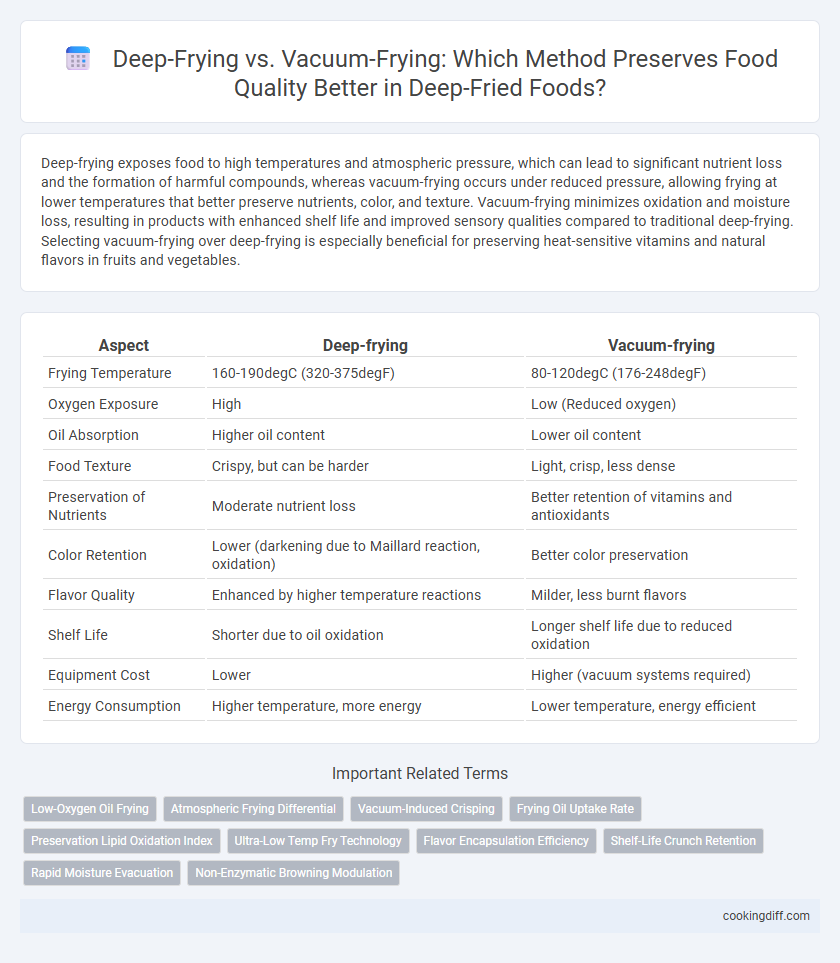

| Aspect | Deep-frying | Vacuum-frying |

|---|---|---|

| Frying Temperature | 160-190degC (320-375degF) | 80-120degC (176-248degF) |

| Oxygen Exposure | High | Low (Reduced oxygen) |

| Oil Absorption | Higher oil content | Lower oil content |

| Food Texture | Crispy, but can be harder | Light, crisp, less dense |

| Preservation of Nutrients | Moderate nutrient loss | Better retention of vitamins and antioxidants |

| Color Retention | Lower (darkening due to Maillard reaction, oxidation) | Better color preservation |

| Flavor Quality | Enhanced by higher temperature reactions | Milder, less burnt flavors |

| Shelf Life | Shorter due to oil oxidation | Longer shelf life due to reduced oxidation |

| Equipment Cost | Lower | Higher (vacuum systems required) |

| Energy Consumption | Higher temperature, more energy | Lower temperature, energy efficient |

Introduction to Deep-Frying and Vacuum-Frying

Deep-frying immerses food in hot oil at temperatures typically between 160degC and 190degC, producing a crispy texture and rich flavor. Vacuum-frying occurs under reduced pressure, allowing frying at lower temperatures, which helps preserve nutritional content and natural colors.

- High-temperature immersion - Deep-frying uses high heat to rapidly cook food, resulting in a crunchy surface and enhanced flavor.

- Low-temperature frying under vacuum - Vacuum-frying reduces oxidation and thermal damage by frying at lower temperatures in a controlled environment.

- Preservation of nutrients and color - Vacuum-frying better maintains vitamins, antioxidants, and vibrant colors compared to traditional deep-frying methods.

How Deep-Frying Works: Process and Principles

Deep-frying involves submerging food in hot oil at temperatures typically between 160-190degC, causing rapid moisture evaporation and forming a crispy outer layer. This process accelerates cooking through heat transfer by convection and conduction, resulting in distinct texture and flavor changes compared to vacuum-frying.

- Heat Transfer Efficiency - Hot oil transfers heat rapidly to food surfaces, promoting quick cooking and crust formation.

- Moisture Evaporation - High temperatures cause water inside the food to vaporize and escape, reducing moisture content.

- Maillard Reaction - Browning occurs due to chemical reactions between amino acids and reducing sugars, enhancing aroma and color.

Understanding Vacuum-Frying Technology

Vacuum-frying technology operates under reduced pressure, allowing food to be fried at lower temperatures compared to traditional deep-frying. This method significantly reduces oil absorption and preserves the natural color, flavor, and nutritional content of the food.

By minimizing oxidation and thermal degradation, vacuum-frying enhances the preservation of heat-sensitive vitamins and antioxidants. The lower temperature environment also decreases the formation of harmful compounds such as acrylamide, making it a healthier alternative to conventional deep-frying.

Oil Absorption and Fat Content Comparison

Deep-frying typically results in higher oil absorption due to the food being submerged in hot oil at temperatures between 160degC and 190degC. This process increases the fat content significantly compared to vacuum-frying, which operates at lower temperatures and reduced pressure, minimizing oil uptake.

Vacuum-frying preserves the food's texture and nutritional quality by reducing oxidation and oil penetration. Foods fried under vacuum conditions show a lower fat content, enhancing health benefits and shelf life. This method is especially effective for delicate or thinly sliced products where reduced oil absorption is critical.

Nutrient Retention in Deep-Frying vs. Vacuum-Frying

Deep-frying exposes food to high temperatures in the presence of oxygen, causing greater degradation of heat-sensitive nutrients such as vitamins A and C. Vacuum-frying reduces oxidation by frying under low pressure, preserving more nutrients and maintaining better flavor and color.

- Heat-sensitive nutrient loss - Deep-frying significantly reduces vitamin retention due to high oxygen exposure and temperatures.

- Oxidation reduction - Vacuum-frying limits oxygen contact, minimizing oxidative damage to antioxidants and essential fatty acids.

- Color and flavor preservation - Vacuum-frying maintains natural hues and flavors better by preventing excessive Maillard reactions.

Vacuum-frying offers superior nutrient retention compared to traditional deep-frying methods.

Impact on Flavor, Texture, and Color

Deep-frying imparts a rich, crispy texture with a golden-brown color due to Maillard reactions, enhancing flavor complexity and surface crunchiness. Vacuum-frying operates at lower temperatures under reduced pressure, preserving natural colors and delicate flavors by minimizing oxidation and thermal degradation.

While deep-frying can create a more intense, caramelized flavor and a firmer texture, it often results in higher oil absorption, potentially affecting taste and mouthfeel. Vacuum-frying yields a lighter, crisp texture with vibrant colors and retained nutritional quality, making it ideal for preserving sensory attributes in heat-sensitive foods.

Shelf Life and Microbial Stability Differences

| Frying Method | Shelf Life | Microbial Stability |

|---|---|---|

| Deep-frying | Typically shorter shelf life due to higher oil absorption and moisture content, promoting faster oxidation and rancidity. | Moderate microbial stability; high temperatures kill most microbes but moisture retention can encourage spoilage upon storage. |

| Vacuum-frying | Extended shelf life resulting from lower frying temperatures and reduced oxygen exposure, which limits oxidation and moisture retention. | Enhanced microbial stability due to reduced water activity and minimal thermal degradation of natural preservatives in the food matrix. |

Health Implications of Both Methods

Deep-frying involves cooking food at high temperatures in oil, which can lead to the formation of harmful trans fats and acrylamide, negatively impacting cardiovascular health. Vacuum-frying operates at lower temperatures under reduced pressure, significantly reducing oil absorption and the generation of toxic compounds, making it a healthier alternative. Studies show that vacuum-fried foods retain more nutrients and have lower fat content compared to traditional deep-fried products, offering better health outcomes.

Industrial and Home Applications

How do deep-frying and vacuum-frying compare in preserving food quality in industrial and home applications? Deep-frying uses high temperatures that can cause oxidation and nutrient loss, while vacuum-frying operates at lower temperatures under reduced pressure, better preserving color, flavor, and nutrients. Industrial settings benefit from vacuum-frying's ability to produce longer shelf-life products, whereas home applications favor traditional deep-frying for simplicity and speed.

Related Important Terms

Low-Oxygen Oil Frying

Vacuum-frying significantly reduces oxidation by frying foods at low pressure and temperature within a low-oxygen environment, preserving nutrients, color, and flavor more effectively than traditional deep-frying. This low-oxygen oil frying method minimizes the formation of harmful compounds and extends the shelf life of fried products while maintaining crispiness and quality.

Atmospheric Frying Differential

Deep-frying exposes food to atmospheric pressure and high temperatures, leading to oxidative degradation and nutrient loss, while vacuum-frying operates under reduced pressure that lowers boiling points, preserving color, flavor, and antioxidant content more effectively. The atmospheric frying differential causes increased lipid oxidation in deep-frying, making vacuum-frying a superior method for maintaining food quality and extending shelf life.

Vacuum-Induced Crisping

Vacuum-frying preserves food quality by reducing oil absorption and oxidation, maintaining color and nutrients more effectively than traditional deep-frying. Vacuum-induced crisping enhances texture by frying under low pressure, which lowers the boiling point of water, resulting in crispier and less greasy products with extended shelf life.

Frying Oil Uptake Rate

Deep-frying typically results in higher frying oil uptake rates due to atmospheric pressure forcing hot oil into porous food structures, often exceeding 25-30% by weight. Vacuum-frying operates under low pressure, significantly reducing oil absorption to around 10-15%, enhancing the preservation of texture and reducing caloric content in the final product.

Preservation Lipid Oxidation Index

Deep-frying typically results in a higher lipid oxidation index due to prolonged exposure to oxygen and elevated temperatures, accelerating the degradation of lipids and reducing product shelf life. Vacuum-frying significantly lowers the lipid oxidation index by frying under reduced oxygen pressure and lower temperatures, preserving the oil quality and enhancing the oxidative stability of the final product.

Ultra-Low Temp Fry Technology

Ultra-Low Temp Fry Technology in deep-frying significantly enhances preservation by minimizing oil absorption and retaining nutritional value compared to traditional vacuum-frying methods. This technique operates at temperatures below 100degC, reducing oxidative degradation and maintaining the food's original color, flavor, and texture more effectively.

Flavor Encapsulation Efficiency

Vacuum-frying significantly enhances flavor encapsulation efficiency compared to traditional deep-frying by reducing oxidation and moisture loss during frying, which preserves volatile flavor compounds more effectively. The lower frying temperature and reduced oxygen environment in vacuum-frying help maintain the natural aroma and taste, resulting in a superior sensory profile and extended shelf life of fried products.

Shelf-Life Crunch Retention

Deep-frying typically results in a shorter shelf-life and faster loss of crunch due to higher moisture content and oxidative degradation, while vacuum-frying significantly extends shelf-life by removing air and reducing oxidation, preserving crispness and texture. Vacuum-fried products maintain crunch retention longer through lower frying temperatures and reduced exposure to oxygen, which inhibits rancidity and staling.

Rapid Moisture Evacuation

Rapid moisture evacuation in deep-frying leads to a crispy texture but can cause nutrient loss and oxidation due to high temperatures; vacuum-frying operates under low pressure, removing moisture more efficiently at lower temperatures, which better preserves color, flavor, and nutritional content. Vacuum-frying reduces oil absorption and minimizes thermal degradation, enhancing the overall quality and shelf life of food products compared to conventional deep-frying.

Deep-frying vs Vacuum-frying for preservation. Infographic

cookingdiff.com

cookingdiff.com