A traditional oil skimmer effectively removes food particles from frying oil, extending its usability during deep-frying but requires frequent manual intervention. An oil separator jug simplifies oil maintenance by allowing sediment to settle and draining clean oil from the top, reducing waste and improving frying quality. Choosing between these tools depends on the desired level of convenience and oil purification efficiency for deep-frying.

Table of Comparison

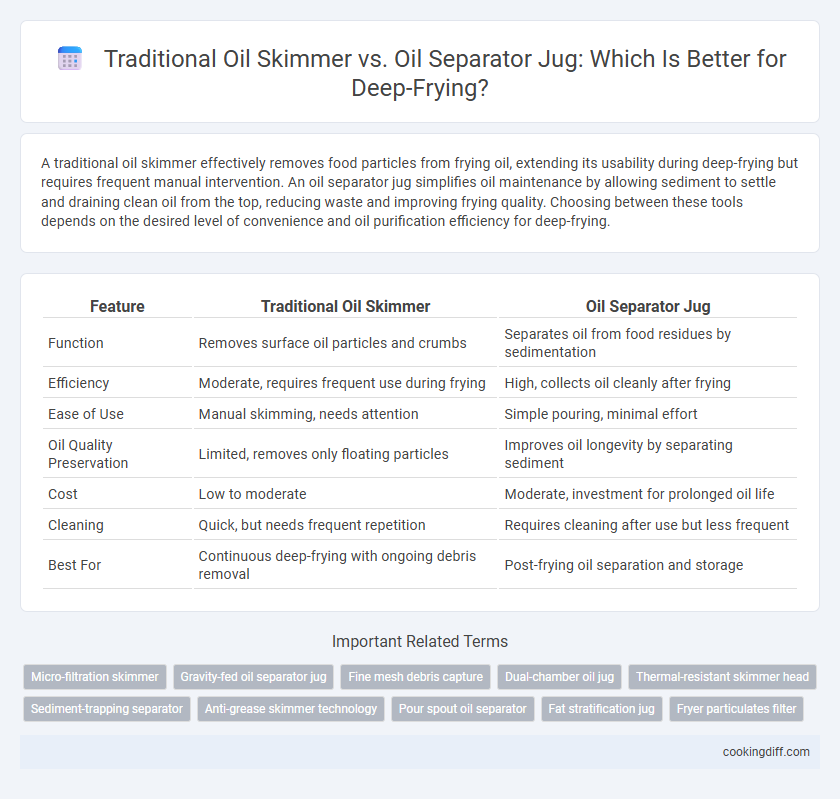

| Feature | Traditional Oil Skimmer | Oil Separator Jug |

|---|---|---|

| Function | Removes surface oil particles and crumbs | Separates oil from food residues by sedimentation |

| Efficiency | Moderate, requires frequent use during frying | High, collects oil cleanly after frying |

| Ease of Use | Manual skimming, needs attention | Simple pouring, minimal effort |

| Oil Quality Preservation | Limited, removes only floating particles | Improves oil longevity by separating sediment |

| Cost | Low to moderate | Moderate, investment for prolonged oil life |

| Cleaning | Quick, but needs frequent repetition | Requires cleaning after use but less frequent |

| Best For | Continuous deep-frying with ongoing debris removal | Post-frying oil separation and storage |

Introduction to Oil Management in Deep-Frying

Effective oil management is crucial in deep-frying to maintain food quality and extend oil usability. Traditional oil skimmers and oil separator jugs serve distinct roles in removing food particles and separating impurities.

- Traditional oil skimmer - Manually removes floating debris and crumbs from hot oil to prevent contamination.

- Oil separator jug - Uses gravity to separate used oil from heavier food residues and water, allowing for easier oil reuse.

- Oil quality preservation - Both tools help reduce oil degradation and improve the lifespan of frying oil by eliminating impurities.

Choosing the right oil management tool enhances frying efficiency and maintains consistent food taste and texture.

What Is a Traditional Oil Skimmer?

| Traditional Oil Skimmer | A traditional oil skimmer is a tool designed to remove food particles and debris from hot oil during deep-frying, enhancing oil lifespan and maintaining food quality. It typically consists of a long handle with a flat, perforated metal or wire mesh surface to strain impurities. Used in commercial kitchens and home frying setups, it helps reduce oil degradation, ensuring safer and tastier fried food. |

What Is an Oil Separator Jug?

What is an oil separator jug and how does it function in deep-frying? An oil separator jug is a kitchen tool designed to separate food particles from used frying oil by allowing sediment to settle at the bottom while pouring clean oil from the top. This method helps improve oil reuse by maintaining oil quality and extending frying oil life compared to traditional oil skimmers that manually remove surface debris.

Key Design Differences: Skimmer vs Separator Jug

The traditional oil skimmer features a flat, perforated design that allows for manual removal of floating food particles and debris from hot oil during deep-frying. It requires regular use and is typically made from stainless steel for durability and heat resistance.

The oil separator jug automates the filtering process by using gravity and mesh filters to separate oil from sediment and moisture. Its airtight design helps preserve oil quality by minimizing exposure to air and contaminants, extending oil usability.

Efficiency in Removing Food Debris

Traditional oil skimmers efficiently remove floating food debris through manual or automated scooping, ensuring cleaner oil and extended frying life. Their design allows rapid debris collection but may miss finer particles embedded in the oil.

Oil separator jugs use gravity and filtration to separate food particles from oil, capturing smaller debris that skimmers often leave behind. This method enhances oil clarity and reduces waste by prolonging oil usability. However, separator jugs typically require longer processing time and may not handle large debris volumes as quickly as skimmers.

Oil Clarity and Reusability Comparison

Traditional oil skimmers effectively remove food particles from deep-frying oil, maintaining oil clarity and extending usability. Their mechanical action enables continuous skimming during frying, reducing flavor contamination and promoting oil longevity.

Oil separator jugs rely on gravity separation after frying to clarify oil, which can be slower and less efficient at removing fine residues. While convenient for occasional use, separator jugs may result in shorter oil reusability due to incomplete impurity removal compared to skimmers.

Ease of Use and Cleaning

Traditional oil skimmers require manual effort to scoop out food particles, making the process time-consuming and less convenient. Oil separator jugs feature a pouring spout that allows easy separation of clean oil from sediment, simplifying both use and cleaning. This design reduces strain and cleanup time, enhancing efficiency in deep-frying maintenance.

Safety Features for Home Deep-Frying

Traditional oil skimmers reduce surface impurities and food debris from deep-frying oil, minimizing fire hazards by preventing clogged filters or burners. Oil separator jugs enhance safety by allowing users to cool and strain oil before reuse, reducing the risk of burns and accidental spills. Both tools contribute to safer home deep-frying environments by maintaining oil quality and preventing contamination-related accidents.

Cost and Durability Analysis

Traditional oil skimmers tend to have higher initial costs but offer greater durability through heavy-duty materials designed for frequent industrial use. Oil separator jugs are more affordable upfront but may require more frequent replacement due to less robust construction.

- Cost Efficiency - Traditional oil skimmers are costlier initially but reduce long-term expenses by minimizing oil waste.

- Material Durability - Skimmers are built with stainless steel or durable plastics, extending their lifespan in high-temperature environments.

- Replacement Frequency - Oil separator jugs generally have a shorter lifespan, leading to increased replacement and maintenance costs.

Related Important Terms

Micro-filtration skimmer

Micro-filtration skimmers enhance deep-frying by efficiently removing fine food particles and impurities from hot oil, preserving oil quality and extending its usable life compared to traditional oil skimmers. Unlike oil separator jugs that rely on gravity settling, micro-filtration skimmers use advanced filtration membranes to trap microscopic debris, resulting in cleaner oil and improved frying consistency.

Gravity-fed oil separator jug

Gravity-fed oil separator jugs offer an efficient alternative to traditional oil skimmers by using density differences to separate clean oil from food particles, significantly extending oil life and improving fry quality. Their design reduces manual effort and oil waste compared to skimmers, making them ideal for maintaining optimal frying oil conditions in commercial kitchens.

Fine mesh debris capture

Traditional oil skimmers utilize coarse mesh screens that often miss fine particulate debris, reducing the effectiveness of oil filtration during deep-frying. In contrast, oil separator jugs feature fine mesh filters designed to capture even the smallest food particles, significantly extending oil life and improving frying quality.

Dual-chamber oil jug

A dual-chamber oil jug optimizes deep-frying by efficiently separating food particles from oil, extending frying oil life and maintaining food quality compared to traditional oil skimmers. This innovative design ensures cleaner oil recycling, reduces oil waste, and improves kitchen hygiene by combining filtration and storage in one container.

Thermal-resistant skimmer head

Thermal-resistant skimmer heads in traditional oil skimmers ensure durability and safety by withstanding high temperatures typical in deep-frying, allowing continuous removal of food particles without degrading. Oil separator jugs lack this high-heat resistance, making skimmers with thermal-resistant heads more efficient and reliable for maintaining oil quality during prolonged deep-frying sessions.

Sediment-trapping separator

Traditional oil skimmers effectively remove floating debris but often miss fine sediment particles, whereas sediment-trapping oil separator jugs capture both floating impurities and settled sediments, enhancing oil clarity and extending frying oil lifespan. Oil separator jugs utilize gravity-based separation technology that traps sediment at the jug's base, reducing the frequency of oil replacement and improving food quality in deep-frying operations.

Anti-grease skimmer technology

Traditional oil skimmers rely on surface tension and manual scooping to remove grease and food particles from deep-frying oil, often leaving behind fine contaminants that degrade oil quality. Oil separator jugs utilize advanced anti-grease skimmer technology with centrifugal separation and fine filtration, significantly improving oil clarity and extending frying oil lifespan by efficiently extracting microscopic impurities.

Pour spout oil separator

The Pour Spout Oil Separator offers a precise and mess-free method for filtering used deep-frying oil, minimizing contaminants and extending oil lifespan compared to traditional oil skimmers that often leave residues behind. Its ergonomic design with a built-in pouring spout ensures easy transfer and storage, enhancing kitchen efficiency and maintaining oil quality for repeated frying cycles.

Fat stratification jug

The fat stratification jug offers precise removal of impurities and lighter oils during deep-frying, preserving oil quality more effectively than traditional oil skimmers that primarily skim surface debris. By enabling layered oil separation, the jug reduces oil waste and extends the usable frying oil lifespan, optimizing both food flavor and operational cost.

Traditional oil skimmer vs oil separator jug for deep-frying. Infographic

cookingdiff.com

cookingdiff.com