Fermentation relies on naturally occurring microbes to break down sugars and produce complex flavors through organic acids, alcohol, and gases, while koji culturing uses the mold Aspergillus oryzae to enzymatically convert starches and proteins into flavorful amino acids and sugars. Koji culturing offers greater control over flavor profiles due to its enzymatic precision, creating rich umami and sweetness that are difficult to achieve with traditional fermentation alone. Combining both methods enhances depth and complexity, making koji an essential tool for advanced flavor development in foods.

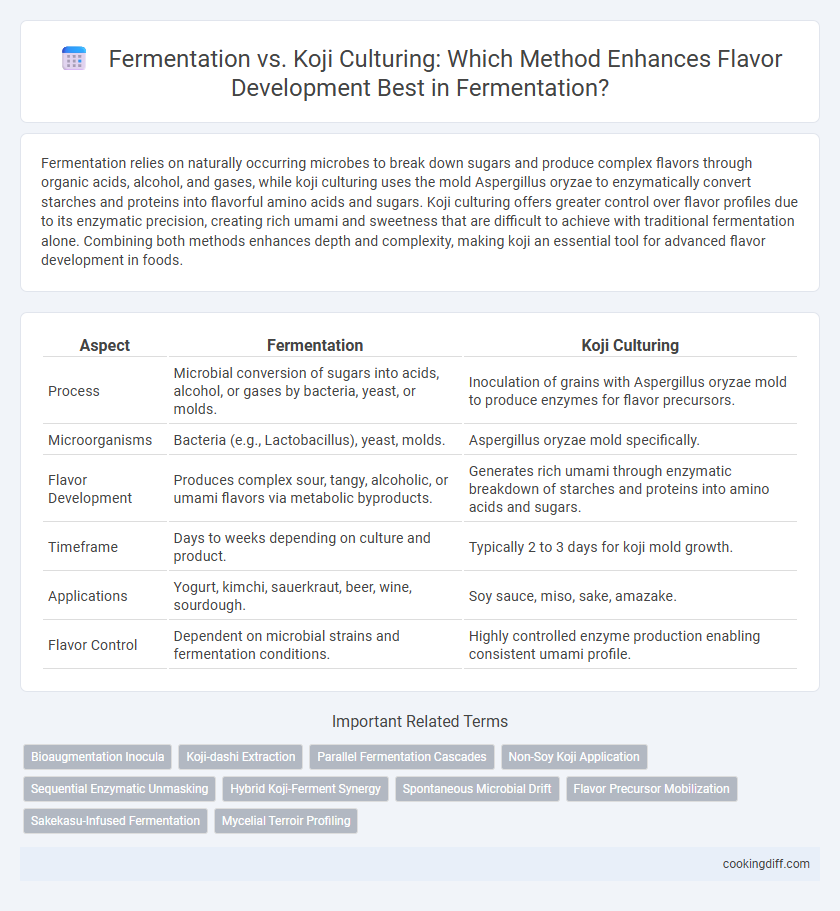

Table of Comparison

| Aspect | Fermentation | Koji Culturing |

|---|---|---|

| Process | Microbial conversion of sugars into acids, alcohol, or gases by bacteria, yeast, or molds. | Inoculation of grains with Aspergillus oryzae mold to produce enzymes for flavor precursors. |

| Microorganisms | Bacteria (e.g., Lactobacillus), yeast, molds. | Aspergillus oryzae mold specifically. |

| Flavor Development | Produces complex sour, tangy, alcoholic, or umami flavors via metabolic byproducts. | Generates rich umami through enzymatic breakdown of starches and proteins into amino acids and sugars. |

| Timeframe | Days to weeks depending on culture and product. | Typically 2 to 3 days for koji mold growth. |

| Applications | Yogurt, kimchi, sauerkraut, beer, wine, sourdough. | Soy sauce, miso, sake, amazake. |

| Flavor Control | Dependent on microbial strains and fermentation conditions. | Highly controlled enzyme production enabling consistent umami profile. |

Understanding Fermentation: An Overview

Fermentation is a metabolic process where microorganisms like bacteria, yeast, or molds convert sugars into acids, gases, or alcohol, enhancing flavor complexity in various foods. Koji culturing specifically utilizes Aspergillus oryzae mold to break down starches and proteins, producing unique umami flavors essential in traditional Japanese cuisine.

Fermentation spans a wide range of applications, including the production of bread, yogurt, and alcoholic beverages, relying on diverse microbial activity to develop characteristic tastes and textures. Koji culturing accelerates enzymatic breakdown, intensifying savory compounds and contributing to the depth of flavors in miso, soy sauce, and sake. Understanding these distinct yet complementary processes is crucial for optimizing flavor profiles in fermented foods.

What is Koji Culturing?

Koji culturing involves inoculating grains, typically rice or barley, with the mold Aspergillus oryzae to initiate enzymatic processes that break down starches into sugars. This method is essential in traditional Japanese fermentation, enhancing umami flavor and sweetness in products like miso and soy sauce.

Fermentation broadly refers to microbial metabolic processes converting sugars into alcohol, acids, or gases, widely used in food preservation and flavor development. Koji culturing specifically amplifies flavor complexity by producing unique enzymes that fermenters alone cannot generate.

Key Microorganisms in Fermentation vs Koji

Fermentation primarily relies on lactic acid bacteria and yeast to convert sugars into complex flavors and aromas, while koji culturing uses Aspergillus oryzae mold to break down starches and proteins, enhancing umami and sweetness. These distinct microorganisms drive different biochemical pathways, resulting in unique flavor profiles and textural changes in fermented foods.

- Lactic Acid Bacteria - These bacteria produce lactic acid, lowering pH and creating tangy, sour notes common in yogurt and kimchi.

- Yeast - Yeast ferment sugars into alcohol and carbon dioxide, contributing to the fruity and alcoholic flavors in beer and bread.

- Aspergillus oryzae - This mold secretes enzymes that hydrolyze starches and proteins, intensifying umami flavors typical in miso and soy sauce.

Flavor Profiles Developed by Fermentation

Fermentation develops complex, tangy, and umami-rich flavors through microbial activity, breaking down sugars and proteins into flavorful compounds. Koji culturing enhances sweetness and savory notes by enzymatically converting starches into sugars and proteins into amino acids, resulting in distinct flavor profiles.

- Fermentation generates organic acids - These acids contribute to sour and tangy flavors characteristic of fermented foods like sauerkraut and kimchi.

- Koji culturing produces glutamic acid - This amino acid intensifies umami taste found in miso and soy sauce.

- Fermentation develops complex aroma compounds - Compounds such as esters and alcohols create layered, rich flavors in products like sourdough and kombucha.

Flavor profiles from fermentation and koji culturing vary significantly, providing versatile options for culinary applications.

Flavor Transformation with Koji Culturing

Koji culturing harnesses Aspergillus oryzae mold to break down starches and proteins into flavorful amino acids and sugars, creating complex umami profiles. This enzymatic process transforms raw ingredients more deeply than traditional fermentation, enhancing savory and sweet nuances.

While fermentation relies on bacteria and yeast to develop acidity and alcohol, koji culturing specifically targets enzymatic flavor amplification without producing alcohol. This precise biochemical transformation results in rich, layered flavors ideal for soy sauce, miso, and sake production.

Traditional Foods: Fermentation vs Koji-Based

| Fermentation | Utilizes natural microbes like bacteria and yeast to convert sugars into acids, alcohol, and gases, enhancing flavor complexity in traditional foods such as kimchi, sauerkraut, and yogurt. |

| Koji Culturing | Employs Aspergillus oryzae mold to break down starches and proteins into amino acids and sugars, intensifying umami flavor in soy sauce, miso, and sake production. |

| Flavor Development | Fermentation produces tangy, sour, and effervescent notes through microbial metabolism, while Koji culturing enriches savory and sweet umami tastes by enzymatic hydrolysis of food components. |

Texture and Aroma Differences

How do fermentation and koji culturing differ in affecting texture and aroma during flavor development? Fermentation typically produces a more complex and tangy aroma with varied textures depending on microbial activity, enhancing depth in foods like yogurt and kimchi. Koji culturing, using Aspergillus oryzae, specifically generates sweet, umami-rich aromas and a tender, smooth texture by breaking down starches and proteins efficiently.

Nutritional Impact: Fermentation vs Koji

Fermentation enhances nutritional value by increasing bioavailability of vitamins and producing beneficial probiotics. Koji culturing, using Aspergillus oryzae, uniquely breaks down starches into sugars and proteins into amino acids, enriching flavor and digestibility without generating live probiotics. Both processes improve nutrient absorption, but fermentation contributes more significantly to gut health through probiotic formation.

Applications in Modern Culinary Arts

Fermentation and Koji culturing both play crucial roles in modern culinary arts by enhancing flavor complexity and depth through microbial activity. Fermentation leverages a diverse range of bacteria and yeasts to develop sour, tangy, and umami profiles in foods such as kimchi, yogurt, and sourdough, while Koji culturing specifically uses the mold Aspergillus oryzae to break down starches and proteins, vital for producing soy sauce, miso, and sake. Chefs increasingly combine these techniques to innovate and refine taste, texture, and aroma in contemporary gastronomy.

Related Important Terms

Bioaugmentation Inocula

Bioaugmentation inocula enhance fermentation by introducing specific microorganisms that optimize flavor compound production, whereas koji culturing relies on filamentous fungi like Aspergillus oryzae to hydrolyze starches and proteins for complex umami profiles. Targeted bioaugmentation can accelerate fermentation kinetics and tailor sensory attributes more precisely than traditional koji methods, improving both consistency and flavor diversity.

Koji-dashi Extraction

Koji culturing enhances flavor development through enzymatic breakdown, producing Koji-dashi with rich umami and complex aroma profiles unmatched by traditional fermentation. The extraction process concentrates amino acids and peptides, intensifying savory depth essential for authentic Japanese cuisine.

Parallel Fermentation Cascades

Fermentation and Koji culturing generate complex flavor profiles through parallel fermentation cascades, where microbial enzymes from Aspergillus oryzae in Koji initiate saccharification alongside lactic acid bacteria-driven fermentation processes. This simultaneous biochemical interaction enhances umami, sweetness, and aromatic compounds more efficiently than traditional single-strain fermentation.

Non-Soy Koji Application

Fermentation and koji culturing both enhance flavor development by breaking down complex ingredients, but non-soy koji applications specifically leverage mold enzymes from Aspergillus oryzae to transform grains, nuts, and seeds into rich umami profiles without relying on soy. Utilizing koji in non-soy substrates accelerates saccharification and amino acid release, creating unique flavor complexities that differ from traditional soy-based fermentation processes.

Sequential Enzymatic Unmasking

Fermentation and Koji culturing both enhance flavor development through Sequential Enzymatic Unmasking, where complex substrates are broken down step-by-step by specific enzymes, releasing hidden aromatic compounds. Koji culturing leverages Aspergillus oryzae enzymes to initiate starch and protein hydrolysis rapidly, creating a rich umami profile distinct from traditional microbial fermentation processes.

Hybrid Koji-Ferment Synergy

Hybrid Koji-ferment synergy enhances flavor development by combining the enzymatic potency of Aspergillus oryzae in koji culturing with the complex microbial activity found in traditional fermentation, producing richer umami profiles and layered aromas. This integration accelerates substrate breakdown and bioactive compound formation, optimizing both texture and taste in fermented foods.

Spontaneous Microbial Drift

Fermentation relies on spontaneous microbial drift, where diverse native microorganisms naturally colonize substrates, creating complex and unpredictable flavor profiles that evolve over time. Koji culturing, by contrast, employs a controlled inoculum of Aspergillus oryzae, ensuring consistent enzymatic breakdown and flavor development, but with less microbial diversity compared to spontaneous fermentation.

Flavor Precursor Mobilization

Fermentation involves the breakdown of complex substrates by microbial enzymes, producing diverse flavor precursors like amino acids and organic acids that contribute to rich, complex tastes. Koji culturing specifically utilizes Aspergillus oryzae to mobilize starches and proteins into simpler sugars and peptides, enhancing flavor precursor availability and intensifying umami and sweet notes in the final product.

Sakekasu-Infused Fermentation

Sakekasu-infused fermentation leverages both traditional fermentation and koji culturing techniques to enhance umami and complex flavor profiles, as the sake lees provide rich amino acids and enzymes that accelerate biochemical transformations. Koji culturing introduces Aspergillus oryzae molds, producing key enzymes that break down starches and proteins, while fermentation by yeast and bacteria develops alcohol and organic acids, resulting in a balanced and deeply nuanced taste unique to sakekasu-infused products.

Fermentation vs Koji culturing for flavor development Infographic

cookingdiff.com

cookingdiff.com