Fermenting miso using open-vat koji fermentation allows for natural aeration and microbial diversity, enhancing flavor complexity and depth. This traditional method exposes the mash to ambient environmental conditions, promoting the growth of beneficial molds and bacteria critical for authentic miso development. In contrast, controlled fermenting systems restrict airflow and microbial variability, resulting in a more consistent but potentially less nuanced flavor profile.

Table of Comparison

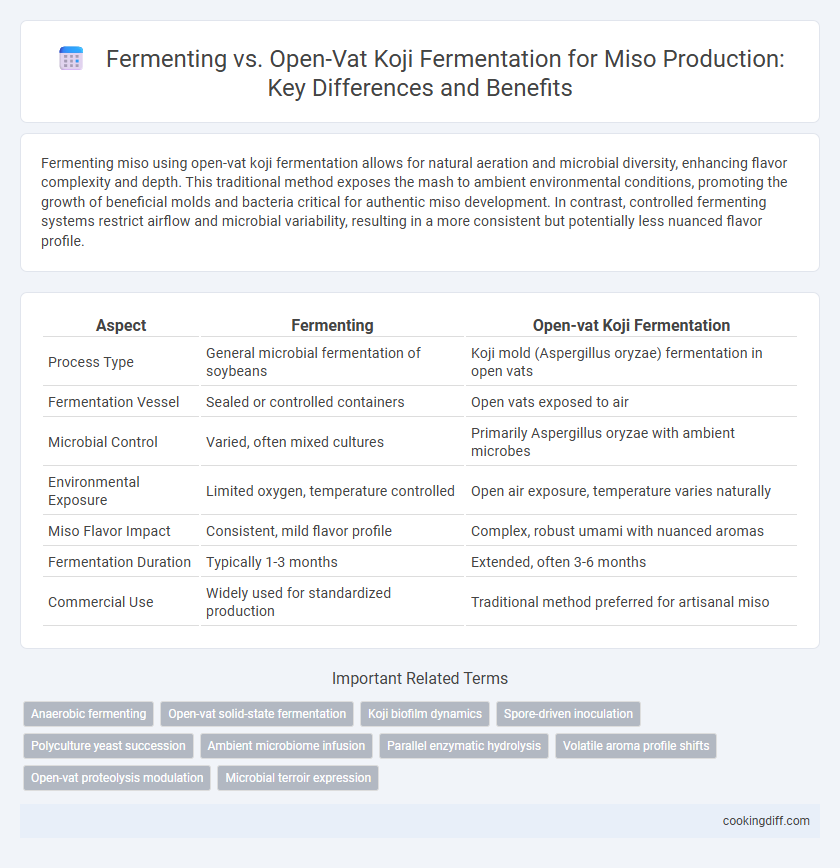

| Aspect | Fermenting | Open-vat Koji Fermentation |

|---|---|---|

| Process Type | General microbial fermentation of soybeans | Koji mold (Aspergillus oryzae) fermentation in open vats |

| Fermentation Vessel | Sealed or controlled containers | Open vats exposed to air |

| Microbial Control | Varied, often mixed cultures | Primarily Aspergillus oryzae with ambient microbes |

| Environmental Exposure | Limited oxygen, temperature controlled | Open air exposure, temperature varies naturally |

| Miso Flavor Impact | Consistent, mild flavor profile | Complex, robust umami with nuanced aromas |

| Fermentation Duration | Typically 1-3 months | Extended, often 3-6 months |

| Commercial Use | Widely used for standardized production | Traditional method preferred for artisanal miso |

Introduction to Miso Fermentation Methods

Miso fermentation involves complex microbial interactions that develop flavor and texture in the final product. Open-vat koji fermentation and controlled fermenting methods represent two primary approaches in traditional miso production.

- Open-vat fermentation - exposes koji inoculated soybeans to natural environmental microbes, encouraging diverse microbial activity.

- Controlled fermentation - uses closed systems with regulated temperature and humidity to standardize microbial growth and flavor development.

- Miso flavor profile - varies depending on the fermentation method, with open-vat often producing richer, more complex umami notes.

Choosing the fermentation technique influences miso's sensory qualities and production consistency.

Understanding Traditional Fermentation in Miso Production

How does open-vat koji fermentation differ from traditional fermenting methods in miso production? Open-vat koji fermentation allows natural environmental microbes to influence the process, enhancing flavor complexity and authenticity. Traditional fermenting methods, by contrast, often rely on controlled conditions to maintain consistency, potentially limiting the depth of umami development.

What Is Open-Vat Koji Fermentation?

Open-vat koji fermentation is a traditional method used in miso production where steamed soybeans and rice inoculated with Aspergillus oryzae are spread in open trays for controlled microbial growth. This technique allows natural air exposure, promoting diverse enzyme activity crucial for developing the complex flavors of miso.

The open-vat process differs from closed or fermenting vessel methods by relying on ambient environmental factors such as temperature and humidity to influence koji growth. Its rustic approach enhances umami profiles but requires careful monitoring to prevent contamination during the fermentation period.

Core Differences: Fermenting vs. Open-Vat Koji Fermentation

Fermenting in miso production involves controlled environmental conditions to develop flavor through enzymatic action, while open-vat koji fermentation exposes the koji mold directly to ambient air in large vats. Open-vat koji fermentation encourages a naturally diverse microbial population, influencing the complexity and depth of miso taste.

- Fermenting Process - Utilizes sealed or semi-sealed containers to regulate temperature and humidity for consistent enzymatic breakdown of soybeans and grains.

- Open-Vat Koji Fermentation - Relies on open-air exposure to cultivate koji mold (Aspergillus oryzae) in large vats, allowing ambient microbes to participate in fermentation.

- Flavor Development - Controlled fermenting typically produces uniform miso flavor, whereas open-vat koji fermentation often results in richer, more complex flavor profiles due to microbial diversity.

Microbial Communities: Closed vs. Open Environments

Closed fermentation environments for miso production maintain a controlled microbial community dominated by beneficial molds like Aspergillus oryzae, reducing contamination risks. Open-vat fermentation allows diverse microbial populations, including wild yeasts and bacteria, which can enhance flavor complexity but increase variability. The choice between closed and open systems significantly influences the consistency and safety of the final miso product.

Flavor Profiles: Impact of Fermentation Method

Fermenting miso using traditional closed systems results in a rich, consistent umami flavor due to controlled temperature and humidity, which enhances the enzymatic breakdown of proteins and starches. Open-vat koji fermentation exposes the mash to ambient microbes, contributing to complex, layered flavor profiles with subtle earthy and fruity notes.

Closed fermentation methods produce smoother, milder miso varieties favored for standard culinary applications, while open-vat fermentation yields robust, artisanal miso prized for gourmet dishes. The choice of fermentation method directly influences the depth, aroma, and taste intensity, impacting final product quality significantly.

Texture & Aroma Variations in Miso

Fermenting miso in closed systems produces a consistent texture with a smooth, rich aroma due to controlled temperature and humidity. Open-vat koji fermentation exposes the mash to natural airflow and wild microflora, creating a more complex, earthy texture and a pronounced, robust aroma profile. These variations significantly influence miso's flavor depth and mouthfeel, tailoring it to different culinary uses.

Food Safety Considerations in Both Methods

Fermenting miso using controlled closed systems offers enhanced food safety by minimizing exposure to contaminants compared to open-vat koji fermentation. Open-vat fermentation allows natural microbial diversity but increases the risk of contamination from environmental pathogens.

- Controlled environment - Closed fermentation vessels reduce contamination risk by preventing airborne microbes and foreign particles from entering the koji culture.

- Microbial monitoring - Open-vat fermentation requires rigorous monitoring to manage unwanted microbial growth that can compromise food safety.

- Sanitation protocols - Both methods demand strict sanitation practices to ensure safe fermentation, but open-vat setups necessitate additional caution due to their higher exposure.

Efficiency and Scalability for Commercial Producers

| Fermenting | Traditional fermenting methods for miso involve open-air conditions, leading to variable microbial activity and slower fermentation rates, which limits scalability and consistency for commercial producers. |

| Open-vat Koji Fermentation | Open-vat koji fermentation offers controlled environmental parameters, enhancing enzyme activity and fermentation efficiency, which improves scalability and uniformity essential for large-scale miso production. |

| Commercial Efficiency & Scalability | Open-vat koji fermentation reduces batch time and increases yield consistency, allowing commercial producers to optimize production schedules and meet larger market demands with reliable quality standards. |

Related Important Terms

Anaerobic fermenting

Anaerobic fermenting in miso production involves sealing the mash to exclude oxygen, promoting the growth of beneficial microbes like Lactobacillus and Tetragenococcus that develop complex flavors and reduce spoilage. Open-vat koji fermentation exposes the mash to air, favoring aerobic molds such as Aspergillus oryzae but increasing oxidation risks and microbial contamination compared to the controlled environment of anaerobic fermentation.

Open-vat solid-state fermentation

Open-vat solid-state fermentation for miso production enables natural airflow and microbial diversity, enhancing enzyme activity and flavor complexity compared to closed fermentation methods. This traditional technique promotes uniform fermentation by allowing gradual moisture evaporation and temperature regulation, resulting in a richer umami profile.

Koji biofilm dynamics

Koji biofilm dynamics in open-vat koji fermentation exhibit increased microbial diversity and enhanced enzyme activity compared to controlled fermenting methods, leading to more complex flavor profiles in miso production. The open environment promotes natural biofilm formation on substrate surfaces, accelerating saccharification rates and improving nutrient availability during fermentation.

Spore-driven inoculation

Spore-driven inoculation in open-vat koji fermentation enhances miso production by promoting natural microbial diversity and robust enzyme activity, leading to complex flavor profiles and improved fermentation efficiency. Compared to controlled fermenting methods, open-vat techniques harness environmental spores, resulting in distinct aromatic compounds and traditional umami development crucial for authentic miso quality.

Polyculture yeast succession

Polyculture yeast succession in open-vat koji fermentation enhances microbial diversity, promoting complex enzymatic activities essential for authentic miso flavor development. In contrast, controlled fermenting environments limit yeast variety, potentially reducing the depth and richness of miso's aromatic and taste profiles.

Ambient microbiome infusion

Fermenting miso using open-vat koji fermentation leverages the ambient microbiome, introducing diverse natural microbes that enrich flavor complexity and depth. In contrast, closed or controlled fermenting environments limit microbial diversity, potentially resulting in a more uniform but less nuanced taste profile.

Parallel enzymatic hydrolysis

Parallel enzymatic hydrolysis in open-vat koji fermentation enables simultaneous breakdown of starches and proteins, enhancing flavor complexity and fermentation speed compared to traditional fermenting methods. This optimized enzymatic activity promotes uniform nutrient release, improving the overall quality and consistency of miso production.

Volatile aroma profile shifts

Fermenting miso through closed systems preserves a consistent volatile aroma profile characterized by rich umami and subtle fruity esters, whereas open-vat koji fermentation promotes greater variability with enhanced production of complex alcohols and organic acids, intensifying earthy and tangy notes. Studies reveal open-vat methods lead to higher microbial diversity, directly influencing the dynamic shifts in aroma compounds critical for traditional miso's distinctive sensory qualities.

Open-vat proteolysis modulation

Open-vat koji fermentation for miso production enhances proteolysis modulation by enabling better control of microbial activity and enzyme distribution, leading to a more consistent breakdown of proteins into amino acids. This method optimizes flavor development and texture by creating an environment that promotes balanced enzymatic reactions compared to traditional closed fermenting techniques.

Fermenting vs Open-vat koji fermentation for miso production. Infographic

cookingdiff.com

cookingdiff.com