Glass crocks offer a clear view of the fermentation process and are easy to clean, making them ideal for beginners. Anaerobic crocks, equipped with water-seal lids, create an oxygen-free environment that enhances fermentation by preventing mold growth and preserving beneficial bacteria. Choosing between glass and anaerobic crocks depends on the need for visibility versus optimal anaerobic conditions during pet fermentation.

Table of Comparison

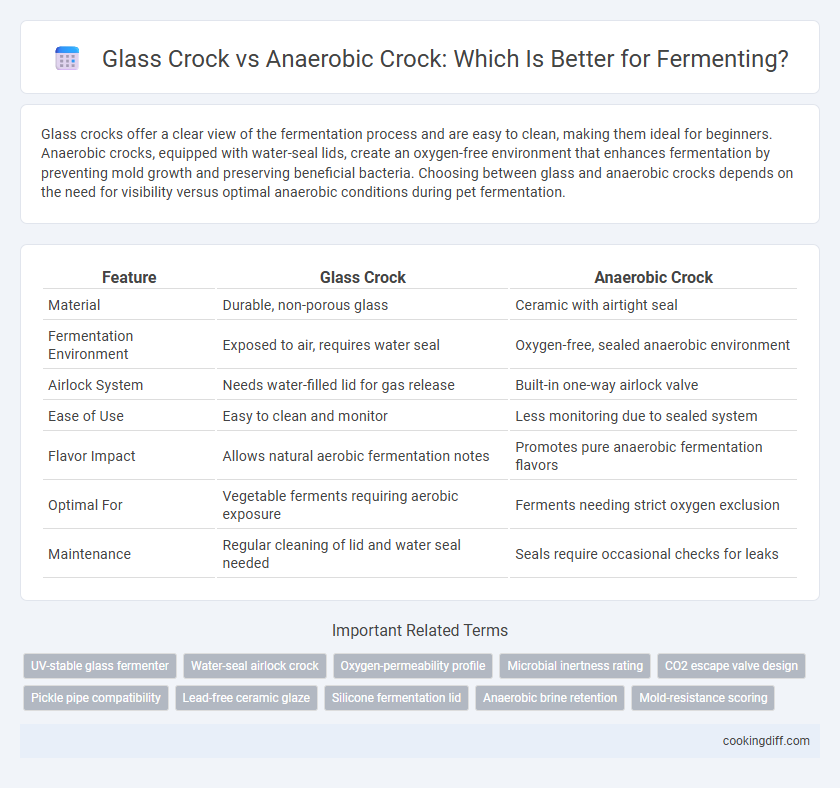

| Feature | Glass Crock | Anaerobic Crock |

|---|---|---|

| Material | Durable, non-porous glass | Ceramic with airtight seal |

| Fermentation Environment | Exposed to air, requires water seal | Oxygen-free, sealed anaerobic environment |

| Airlock System | Needs water-filled lid for gas release | Built-in one-way airlock valve |

| Ease of Use | Easy to clean and monitor | Less monitoring due to sealed system |

| Flavor Impact | Allows natural aerobic fermentation notes | Promotes pure anaerobic fermentation flavors |

| Optimal For | Vegetable ferments requiring aerobic exposure | Ferments needing strict oxygen exclusion |

| Maintenance | Regular cleaning of lid and water seal needed | Seals require occasional checks for leaks |

Introduction: Understanding Fermentation Crocks

What are the key differences between glass crocks and anaerobic crocks for fermenting? Glass crocks provide a non-reactive surface ideal for monitoring fermentation without affecting flavor, while anaerobic crocks create a sealed environment that prevents oxygen exposure, crucial for maintaining lactic acid bacteria activity. Choosing the right crock depends on balancing visibility needs with the benefits of an oxygen-free environment to optimize fermentation results.

What is a Glass Crock?

| Glass Crock | A Glass Crock is a non-porous fermentation vessel made entirely of glass, which prevents unwanted absorption of flavors and odors during the fermenting process. |

| Material Benefits | Its smooth, inert surface resists staining and is easy to clean, making it ideal for long-term fermentation of vegetables and sauerkraut. |

| Usage | Glass crocks provide an oxygen-free environment when properly sealed, preserving the integrity of lactic acid bacteria essential for successful fermentation. |

What is an Anaerobic Crock?

An anaerobic crock is a specialized fermenting vessel designed to create a sealed, oxygen-free environment that promotes the growth of beneficial bacteria while preventing mold and yeast contamination. Unlike traditional glass crocks, anaerobic crocks use water seals or airtight lids to maintain anaerobic conditions essential for consistent fermentation results. This setup enhances the preservation of nutrients and flavor development in fermented vegetables such as sauerkraut and kimchi.

Material Differences: Glass vs Anaerobic Crocks

Glass crocks offer a non-porous surface that does not absorb odors or flavors, ensuring a pure fermentation environment. Anaerobic crocks, typically made from ceramic or clay with specialized airlock systems, maintain an oxygen-free environment essential for anaerobic fermentation.

- Non-Porous Surface - Glass crocks resist absorption, making them easier to clean and ideal for multiple uses.

- Airlock System - Anaerobic crocks use water-sealed lids or valves to prevent oxygen entry, promoting safe lacto-fermentation.

- Material Durability - Glass is fragile and prone to breakage, whereas ceramic anaerobic crocks are heavy but more impact-resistant.

The choice between glass and anaerobic crocks depends on the fermenter's preference for material interaction and oxygen control during fermentation.

Oxygen Control in Fermentation

Glass crocks provide limited oxygen control during fermentation, allowing some air exchange that can influence the development of beneficial microbes. Anaerobic crocks create a sealed environment that minimizes oxygen exposure, promoting optimal conditions for lactic acid bacteria.

- Glass crock oxygen permeability - Glass crocks are non-porous but typically lack airtight lids, resulting in partial oxygen exposure that can alter fermentation outcomes.

- Anaerobic crock sealing mechanism - Anaerobic crocks use water-tight seals or airlocks to restrict oxygen entry, which helps maintain an anaerobic environment critical for stable fermentation.

- Impact on microbial activity - Controlled oxygen levels in anaerobic crocks support favorable fermentation by preventing aerobic spoilage microorganisms prevalent in glass crocks.

Flavor and Texture Outcomes

Glass crocks offer a neutral environment that preserves the natural flavors of fermenting vegetables without imparting any metallic or plastic aftertaste. Anaerobic crocks create a sealed environment that enhances complex sour notes and tenderizes texture through consistent oxygen-free fermentation.

- Flavor Preservation - Glass crocks maintain clean, pure fermentation flavors by eliminating interaction with container materials.

- Enhanced Sourness - Anaerobic crocks promote deeper tanginess due to oxygen exclusion and stable microbial activity.

- Texture Development - Anaerobic crocks yield softer, more uniformly fermented textures from controlled anaerobic conditions.

Ease of Use and Maintenance

Glass crocks offer high visibility, allowing users to easily monitor the fermentation process without opening the container, which helps maintain consistent conditions. They are generally lighter and simpler to clean, as glass is non-porous and resists odors and stains.

Anaerobic crocks, designed to create an oxygen-free environment, require more careful setup and maintenance to ensure proper sealing and prevent air leakage. Their mechanism can be more complex to clean thoroughly, demanding regular inspection to avoid mold or unwanted bacterial growth in hidden areas.

Cleaning and Durability

Glass crocks offer non-porous surfaces that resist stains and odors, making them easier to clean thoroughly after each ferment. Their durability is high against acids and corrosion but glass can chip or break if dropped.

Anaerobic crocks, designed to limit oxygen exposure, often feature ceramic materials that may absorb some residues, requiring more careful cleaning to avoid contamination. They generally possess robust durability with thick walls and heavy construction, but glazed finishes can crack over time. Proper maintenance extends their lifespan significantly during repeated fermenting cycles.

Cost and Availability

Glass crocks for fermenting are generally more affordable and widely available in various sizes and designs through online retailers and kitchen specialty stores. Their transparency allows easy monitoring of the fermentation process without disturbing the contents.

Anaerobic crocks, designed to create an oxygen-free environment ideal for fermentation, tend to be pricier due to specialized features like airlocks and sealed lids. They are less commonly found in general stores but can be sourced from niche suppliers and fermentation-focused retailers.

Related Important Terms

UV-stable glass fermenter

UV-stable glass fermenters offer superior protection against light-induced spoilage, ensuring optimal anaerobic conditions during fermentation compared to traditional glass crocks. Their durable, non-reactive material preserves microbial integrity and flavor profile, making them ideal for consistent, high-quality fermenting processes.

Water-seal airlock crock

Water-seal airlock crocks provide an anaerobic environment essential for optimal fermentation by using a water channel that traps gases while preventing oxygen and contaminants from entering. Unlike traditional glass crocks, these specialized crocks maintain consistent anaerobic conditions, reducing the risk of mold growth and ensuring cleaner, more reliable fermentation outcomes.

Oxygen-permeability profile

Glass crocks offer minimal oxygen permeability due to their non-porous surface, creating a predominantly anaerobic environment essential for controlled fermentation. Anaerobic crocks utilize airlocks or special lids to prevent oxygen ingress, maintaining an oxygen-free environment that inhibits unwanted aerobic bacteria and promotes optimal microbial activity.

Microbial inertness rating

Glass crocks exhibit a high microbial inertness rating, preventing unwanted bacteria growth and preserving fermentation integrity. Anaerobic crocks also offer excellent microbial resistance by eliminating oxygen exposure, which further inhibits spoilage microbes and supports a controlled fermentation environment.

CO2 escape valve design

Glass crocks rely on manual methods for CO2 release, often requiring lids to be lifted to avoid pressure buildup, whereas anaerobic crocks feature specialized airlock or CO2 escape valve designs that allow continuous gas release while preventing oxygen entry, ensuring optimal fermentation conditions and reducing spoilage risk. These valve systems create an anaerobic environment that enhances microbial activity and preserves the ferment's flavor and texture.

Pickle pipe compatibility

Glass crocks provide a non-reactive surface ideal for fermenting but often lack built-in pickle pipe compatibility, requiring separate weights to keep vegetables submerged. Anaerobic crocks feature integrated pickle pipes that release gases and prevent oxygen exposure, enhancing fermentation by maintaining an airtight environment tailored for optimal pickle preservation.

Lead-free ceramic glaze

Glass crocks are non-porous and naturally inert, ensuring no leaching of harmful substances during fermentation, while anaerobic crocks use lead-free ceramic glaze designed to withstand acidic environments without contaminating fermented foods. The lead-free ceramic glaze in anaerobic crocks provides a safe, chemical-resistant barrier that maintains flavor integrity and prevents lead exposure, making both options ideal for healthy fermentation practices.

Silicone fermentation lid

Silicone fermentation lids provide a flexible, airtight seal ideal for both glass crocks and anaerobic crocks, preventing oxygen exposure and promoting optimal fermentation conditions. These lids enhance the anaerobic environment crucial for producing consistent, flavorful fermented foods while reducing mold risk and controlling gas release.

Anaerobic brine retention

Anaerobic crocks feature a specialized water-sealed airlock system that maintains brine retention, creating an oxygen-free environment essential for optimal fermentation and preventing mold growth. In contrast, glass crocks lack this built-in anaerobic seal, requiring additional equipment to achieve similar brine retention and anaerobic conditions.

Glass crock vs Anaerobic crock for fermenting. Infographic

cookingdiff.com

cookingdiff.com