Glass fermentation containers generally weigh more than plastic ones, providing greater stability during the fermentation process. Plastic containers are lighter and easier to handle but may be less durable and can retain odors or stains over time. Choosing between plastic and glass often depends on balancing the benefits of weight and durability with convenience and ease of use in fermenting pet foods.

Table of Comparison

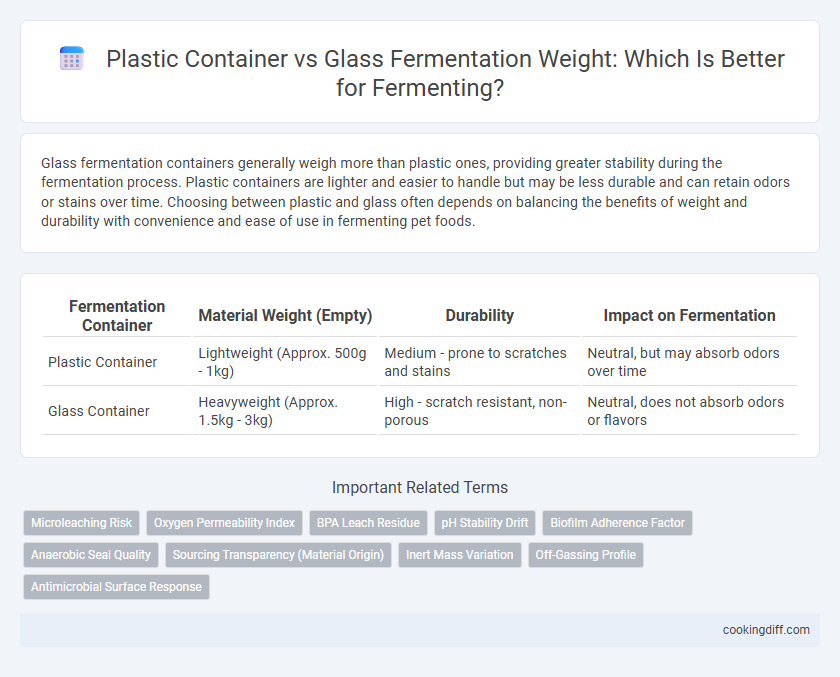

| Fermentation Container | Material Weight (Empty) | Durability | Impact on Fermentation |

|---|---|---|---|

| Plastic Container | Lightweight (Approx. 500g - 1kg) | Medium - prone to scratches and stains | Neutral, but may absorb odors over time |

| Glass Container | Heavyweight (Approx. 1.5kg - 3kg) | High - scratch resistant, non-porous | Neutral, does not absorb odors or flavors |

Introduction to Fermentation Weights

| Fermentation weights play a crucial role in maintaining submersion of produce during the fermentation process, preventing mold and spoilage. Plastic fermentation weights are typically lightweight, averaging around 150 to 300 grams, offering ease of handling and durability without the risk of breakage. Glass weights, often weighing between 500 to 800 grams, provide a stable, heavier option that helps maintain consistent pressure but require careful handling to avoid cracking or chipping. |

Why Use Weights in Fermentation?

Weights play a crucial role in fermentation by keeping the fermenting food submerged below the brine to prevent mold and bad bacteria growth. Glass containers are often heavier, which naturally aids in maintaining pressure and submersion, whereas plastic containers require additional weights to achieve the same effect.

Using weights ensures an anaerobic environment necessary for proper fermentation by minimizing oxygen exposure. While glass fermentation weights are durable and non-reactive, plastic weights must be food-grade to avoid contamination during the fermentation process.

Plastic vs Glass Weights: Material Overview

Plastic fermentation containers are significantly lighter than glass, making them easier to handle and transport during the fermentation process. Glass containers, although heavier, provide superior chemical stability and do not absorb odors or stains, which is important for maintaining fermentation quality.

- Plastic containers weigh less - Typically, plastic weighs 1/5th to 1/10th of glass of the same volume, reducing strain and risk during handling.

- Glass containers provide durability - The added weight of glass contributes to stability and resistance to scratching or chemical reactions.

- Weight impacts fermentation maintenance - Lighter plastic makes frequent inspections and movements easier, while heavier glass offers better long-term preservation of ferment characteristics.

Food Safety: Plastic vs Glass Weights

Glass fermentation containers are heavier, providing stability that reduces the risk of tipping during the fermentation process, enhancing food safety. Plastic containers, though lighter and easier to handle, may pose risks due to potential chemical leaching, especially under acidic fermentation conditions. Choosing glass minimizes contamination concerns and maintains product integrity through its non-porous, inert nature.

Durability and Longevity of Fermentation Weights

Glass fermentation weights offer superior durability and chemical resistance, making them ideal for long-term use without degrading or interacting with the fermenting product. Their non-porous surface prevents microbial contamination, ensuring consistent fermentation quality over time.

Plastic fermentation weights are lighter and less fragile but tend to scratch and absorb odors or stains, which can compromise cleanliness and longevity. While more affordable, plastic weights often require frequent replacement due to wear and potential leaching of chemicals during extended fermentation.

Ease of Cleaning: Plastic Compared to Glass

Plastic fermentation containers are significantly lighter than glass, making them easier to handle during cleaning. However, plastic is more prone to scratches that can harbor bacteria, complicating thorough sanitation.

- Weight Difference - Plastic containers weigh less, reducing the effort needed to move and wash them compared to heavier glass jars.

- Surface Durability - Glass surfaces resist scratches and staining, ensuring a more hygienic and easier cleaning process.

- Bacterial Risks - Scratches and wear on plastic containers create crevices for bacteria, increasing cleaning challenges and potential contamination.

Glass fermentation vessels offer superior ease of cleaning due to their smooth, non-porous surfaces despite their heavier weight.

Potential for Leaching or Chemical Interactions

Plastic containers used for fermenting carry a higher risk of leaching chemicals, especially when exposed to acidic environments common in fermentation processes. Glass fermentation weights are inert and do not interact with the fermenting contents, ensuring chemical stability and safety.

- Plastic leaching potential - Certain plastics may release BPA, phthalates, or other compounds under acidic and warm fermentation conditions.

- Glass inertness - Glass fermentation weights do not react chemically with fermenting food, preventing contamination.

- Food safety implications - Choosing glass fermentation weights reduces the risk of chemical contamination and preserves flavor integrity.

Weight and Design: Sinking Power and Fit

Glass fermentation containers typically weigh more than plastic ones, providing superior sinking power to keep weights and vegetables submerged during fermentation. The heavier design of glass jars improves stability, reducing the risk of floating ingredients that can lead to spoilage. Plastic containers, while lighter and more portable, may require additional external weights to maintain proper submersion and fit within fermentation setups.

Cost Comparison: Plastic vs Glass Weights

Plastic fermentation containers typically weigh significantly less than glass ones, resulting in lower shipping and handling costs. This weight difference often makes plastic a more cost-effective choice for large-scale fermenting projects.

Glass containers, while heavier and more expensive to transport, offer durability and reusability that can offset initial costs over time. The added weight increases shipping fees and complicates manual handling, potentially raising overall expenses. Choosing between plastic and glass depends on balancing upfront costs with long-term benefits in fermenting efficiency and sustainability.

Related Important Terms

Microleaching Risk

Glass fermentation containers significantly reduce microleaching risks compared to plastic containers, as glass is non-porous and inert, preventing harmful chemical transfer into the fermenting product. Plastic containers, especially those made from low-grade plastics, may leach endocrine-disrupting compounds and plasticizers into the fermenting mixture, posing potential health hazards.

Oxygen Permeability Index

Glass fermentation containers have a significantly lower Oxygen Permeability Index compared to plastic containers, ensuring minimal oxygen exposure that preserves the integrity of the fermenting product. Plastic containers, with higher oxygen permeability, increase the risk of aerobic contamination and spoilage, making glass the preferred choice for controlled anaerobic fermentation processes.

BPA Leach Residue

Glass fermentation containers are preferred over plastic due to the absence of BPA leach residue, which can contaminate fermented products and pose health risks. Plastic containers, especially those containing BPA, may release harmful chemicals during fermentation, impacting both safety and flavor integrity.

pH Stability Drift

Glass fermentation containers exhibit superior pH stability with minimal drift due to their non-reactive, impermeable surface, while plastic containers can leach chemicals and absorb acids, leading to fluctuations in pH during fermentation. The weight of glass vessels contributes to a stable environment by reducing movement and temperature variations, which further supports consistent pH levels compared to the lighter and more flexible plastic alternatives.

Biofilm Adherence Factor

Glass fermentation containers exhibit a lower biofilm adherence factor compared to plastic due to their non-porous, smooth surface which limits microbial attachment and biofilm formation. Plastic containers, being more porous and prone to scratches, increase the biofilm adherence factor, potentially affecting fermentation hygiene and microbial consistency.

Anaerobic Seal Quality

Glass fermentation containers provide a superior anaerobic seal compared to plastic containers, minimizing oxygen exposure and reducing the risk of contamination during the fermenting process. The weight of glass contributes to a more stable, airtight environment, ensuring consistent fermentation quality and improved preservation of flavors.

Sourcing Transparency (Material Origin)

Glass fermentation containers typically provide greater sourcing transparency as they are made from natural, recyclable materials with traceable origins, ensuring minimal chemical leaching during fermentation. Plastic containers, while lighter and often more affordable, may lack clear material origin disclosure, raising concerns about potential contaminants and environmental impact throughout the fermenting process.

Inert Mass Variation

Glass fermentation containers typically have a higher inert mass compared to plastic containers, which can influence thermal stability and fermentation consistency. Plastic containers, being lighter with lower inert mass, allow faster temperature fluctuations that may affect microbial activity during fermentation.

Off-Gassing Profile

Glass fermentation containers exhibit a lower off-gassing profile compared to plastic containers, allowing for more stable fermentation environments due to their impermeability and non-reactive surface. Plastic containers tend to off-gas trace amounts of compounds that can influence microbial activity and flavor development, making glass a preferred choice for precise fermentation control.

Plastic container vs Glass fermentation weight for fermenting. Infographic

cookingdiff.com

cookingdiff.com