Plastic lids provide a simple barrier to contaminants but often lack the necessary ventilation, increasing the risk of pressure buildup during fermenting. Airlock lids allow gases to escape while keeping oxygen and unwanted bacteria out, resulting in a safer and more controlled fermentation environment. Choosing an airlock lid enhances the quality and consistency of fermented pet foods by preventing spoilage and maintaining optimal anaerobic conditions.

Table of Comparison

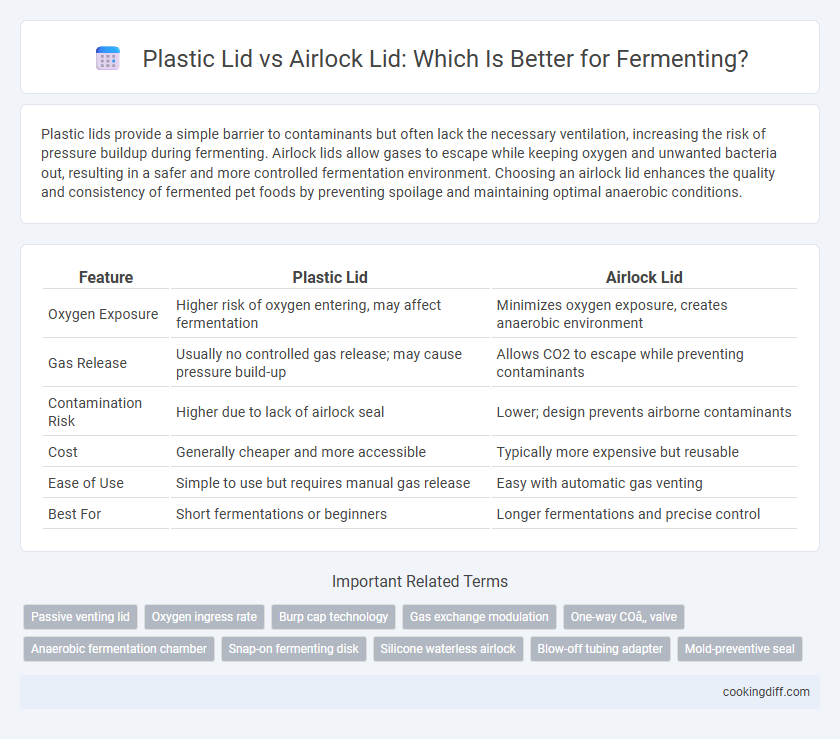

| Feature | Plastic Lid | Airlock Lid |

|---|---|---|

| Oxygen Exposure | Higher risk of oxygen entering, may affect fermentation | Minimizes oxygen exposure, creates anaerobic environment |

| Gas Release | Usually no controlled gas release; may cause pressure build-up | Allows CO2 to escape while preventing contaminants |

| Contamination Risk | Higher due to lack of airlock seal | Lower; design prevents airborne contaminants |

| Cost | Generally cheaper and more accessible | Typically more expensive but reusable |

| Ease of Use | Simple to use but requires manual gas release | Easy with automatic gas venting |

| Best For | Short fermentations or beginners | Longer fermentations and precise control |

Understanding Fermentation: The Role of Container Lids

The type of container lid significantly impacts the fermentation process by controlling gas exchange and preventing contamination. Plastic lids create a sealed environment that can trap gases, whereas airlock lids allow carbon dioxide to escape while blocking oxygen and contaminants.

- Plastic Lid - Seals the container tightly, which may cause pressure buildup during active fermentation and risk lid popping off.

- Airlock Lid - Features a valve system that releases excess gas while preventing oxygen and airborne microbes from entering the fermenting vessel.

- Fermentation Control - Proper gas exchange via an airlock lid helps maintain anaerobic conditions essential for safe and efficient fermentation.

Plastic Lid Overview: Design, Types, and Usage

| Feature | Plastic Lid Overview |

|---|---|

| Design | Plastic lids for fermenting are typically made from food-grade, BPA-free plastic and are designed with a simple, airtight seal to prevent contamination. Some models include built-in holes or valves to accommodate airlocks, allowing gas to escape while keeping oxygen out. |

| Types | Common types include flat snap-on lids, screw-on lids, and specialized fermentation lids with removable valves for inserting airlocks. Flat plastic lids are economical and reusable, while screw-on versions offer a tighter seal and more durability. |

| Usage | Plastic lids are ideal for short to medium-term fermentation projects and are suitable for beginners due to ease of use and cleaning. They allow for pressure control by either manual venting or pairing with an airlock system, ensuring anaerobic fermentation conditions. |

What Is an Airlock Lid? Functionality and Features

An airlock lid is a specialized fermenting cover designed to release carbon dioxide while preventing oxygen and contaminants from entering the fermentation vessel. It maintains an anaerobic environment essential for safe and effective fermentation.

- Gas Release - Allows carbon dioxide produced during fermentation to escape without letting air in, reducing the risk of mold and spoilage.

- Contamination Prevention - Creates a barrier against airborne bacteria and wild yeasts, ensuring a controlled fermenting process.

- Pressure Regulation - Balances internal pressure to avoid explosion risks often associated with airtight plastic lids.

Using an airlock lid enhances fermentation safety, consistency, and product quality compared to a simple plastic lid.

Oxygen Management: Plastic vs Airlock Lids

Plastic lids provide a basic seal but often allow limited oxygen exchange, which can lead to spoilage during fermentation. Airlock lids, equipped with water or silicone valves, enable controlled gas release, preventing oxygen ingress while allowing carbon dioxide to escape. Effective oxygen management via airlock lids promotes anaerobic conditions essential for successful fermentation and flavor development.

Contamination Risks: Comparing Plastic and Airlock Lids

Plastic lids often lack an airtight seal, increasing the risk of contamination by allowing airborne bacteria and mold spores to enter the fermenting vessel. This can lead to spoilage and off-flavors in fermented products such as kimchi or sauerkraut.

Airlock lids create a controlled environment by releasing carbon dioxide while preventing oxygen and contaminants from entering, significantly reducing contamination risks. They maintain anaerobic conditions ideal for safe fermentation and consistent microbial growth.

Ease of Use and Maintenance: Which Lid Wins?

Which lid offers greater ease of use and maintenance for fermenting: plastic lid or airlock lid? Plastic lids are simpler to install and clean, making them convenient for beginners and quick fermentations. Airlock lids require more careful setup and regular cleaning to prevent contamination, but they provide superior gas release control during long-term fermentation.

Flavor Development: Impact of Lid Choice on Fermentation

Plastic lids create a sealed environment that can trap gases and potentially lead to unwanted off-flavors due to anaerobic conditions during fermentation. Airlock lids allow gases to escape while preventing oxygen and contaminants from entering, promoting a balanced flavor profile by maintaining optimal fermentation conditions. Choosing an airlock lid supports the development of complex, nuanced flavors by ensuring consistent carbon dioxide release and minimizing oxidation risks.

Affordability and Availability: Cost Comparison

Plastic lids for fermenting are generally more affordable and widely available compared to airlock lids, making them a popular choice for beginners and budget-conscious hobbyists. Standard plastic lids can be found in most kitchen supply stores and online marketplaces, often costing just a few dollars each.

Airlock lids, while slightly more expensive, provide a specialized seal that helps prevent contamination and allows gas to escape during fermentation, which can justify the higher price for serious fermenters. These lids typically range from $5 to $15 depending on the brand and quality. Availability might be limited to specialty stores or online fermentation shops, but the investment often results in better fermentation control and outcomes.

Best Applications: When to Use Plastic vs Airlock Lids

Plastic lids work well for short-term fermentations and beginner projects since they are inexpensive and easy to use but lack precise gas exchange control. Airlock lids are ideal for longer fermentations requiring controlled CO2 release to prevent contamination and ensure anaerobic conditions.

- Plastic lids are best for quick, small-batch ferments - They provide a simple seal that retains gases but may allow pressure buildup without release.

- Airlock lids excel in extended fermentation processes - These lids allow CO2 to escape while blocking oxygen, reducing spoilage risk.

- Use airlock lids for sensitive ferments like kimchi and sauerkraut - Controlled environment fosters consistent flavor development and safety.

Related Important Terms

Passive venting lid

Passive venting lids are designed to allow carbon dioxide to escape during fermentation while preventing oxygen and contaminants from entering, creating an anaerobic environment ideal for fermenting foods. Compared to airlock lids, plastic passive venting lids offer a simpler, low-maintenance solution that reduces the risk of contamination and preserves the natural fermentation process without requiring water or complex setups.

Oxygen ingress rate

Plastic lids for fermenting jars typically allow higher oxygen ingress rates compared to specialized airlock lids, increasing the risk of unwanted aerobic microbial growth. Airlock lids maintain an anaerobic environment by permitting carbon dioxide to escape while preventing oxygen from entering, optimizing conditions for controlled fermentation.

Burp cap technology

Burp cap technology in fermenting lids offers a convenient way to release built-up carbon dioxide while preventing oxygen and contaminants from entering the jar, enhancing anaerobic fermentation conditions. Compared to traditional plastic lids, airlock lids with burp caps ensure consistent pressure regulation and reduce the risk of jar explosions during the fermentation process.

Gas exchange modulation

Airlock lids provide precise gas exchange modulation by releasing carbon dioxide while preventing oxygen ingress, essential for anaerobic fermentation. Plastic lids lack this specific control, often leading to unpredictable gas buildup and potential oxidation, which can compromise ferment quality.

One-way CO₂ valve

A one-way CO2 valve in airlock lids effectively releases gas buildup during fermentation while preventing oxygen and contaminants from entering, ensuring a controlled anaerobic environment ideal for preserving flavor and preventing spoilage. Plastic lids without this valve often allow excess pressure to accumulate or permit oxygen exposure, increasing the risk of fermentation off-flavors and mold growth.

Anaerobic fermentation chamber

Plastic lids often fail to maintain an effective anaerobic fermentation chamber due to imperfect seals that allow oxygen infiltration, increasing the risk of spoilage and contamination. Airlock lids create a controlled anaerobic environment by releasing carbon dioxide while preventing oxygen entry, crucial for preserving flavor and preventing mold growth in fermenting vegetables, kombucha, and other brined products.

Snap-on fermenting disk

The Snap-on fermenting disk, a plastic lid variant, offers a convenient, airtight seal to prevent oxygen exposure while allowing gas to escape during fermentation, minimizing contamination risks. Compared to traditional airlock lids, snap-on lids simplify the process by eliminating the need for added water and complex setups, making them ideal for home fermenters seeking efficiency and ease of use.

Silicone waterless airlock

Silicone waterless airlocks provide a more reliable and mess-free fermentation environment compared to traditional plastic lids, eliminating the risk of contamination by allowing gases to escape without letting outside air in. These airlocks maintain optimal anaerobic conditions essential for consistent lactic acid bacteria activity, enhancing flavor development and fermentation safety.

Blow-off tubing adapter

A blow-off tubing adapter on a plastic lid provides an efficient escape route for excess gas during vigorous fermentation, reducing the risk of pressure build-up and potential spills. Unlike traditional airlock lids, the plastic lid with a blow-off adapter allows for greater gas release capacity, making it ideal for high-activity fermentations such as beer or kimchi.

Plastic lid vs Airlock lid for fermenting. Infographic

cookingdiff.com

cookingdiff.com