Wood barrels provide a traditional fermentation environment that enhances flavor development through natural micro-oxygenation and absorption of fermentation byproducts. Food-safe plastic fermentation bags offer a lightweight, cost-effective, and easy-to-clean alternative that reduces contamination risks and allows for flexible batch sizes. Choosing between wood and plastic depends on desired flavor complexity, maintenance commitment, and storage conditions for fermenting pet foods.

Table of Comparison

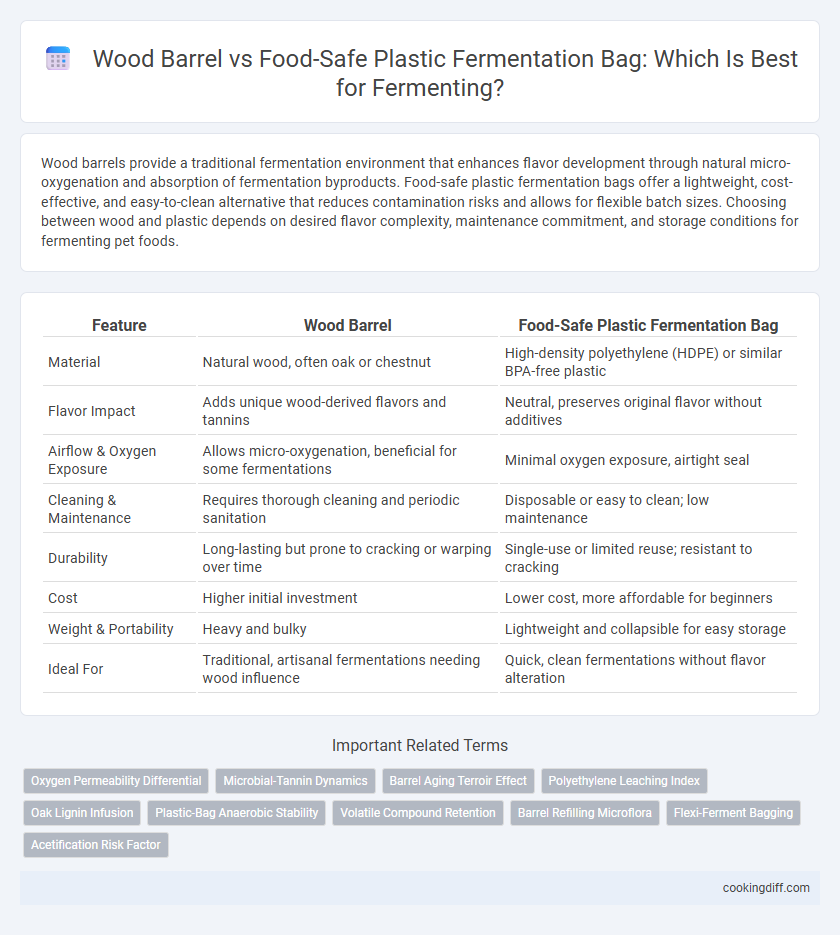

| Feature | Wood Barrel | Food-Safe Plastic Fermentation Bag |

|---|---|---|

| Material | Natural wood, often oak or chestnut | High-density polyethylene (HDPE) or similar BPA-free plastic |

| Flavor Impact | Adds unique wood-derived flavors and tannins | Neutral, preserves original flavor without additives |

| Airflow & Oxygen Exposure | Allows micro-oxygenation, beneficial for some fermentations | Minimal oxygen exposure, airtight seal |

| Cleaning & Maintenance | Requires thorough cleaning and periodic sanitation | Disposable or easy to clean; low maintenance |

| Durability | Long-lasting but prone to cracking or warping over time | Single-use or limited reuse; resistant to cracking |

| Cost | Higher initial investment | Lower cost, more affordable for beginners |

| Weight & Portability | Heavy and bulky | Lightweight and collapsible for easy storage |

| Ideal For | Traditional, artisanal fermentations needing wood influence | Quick, clean fermentations without flavor alteration |

Introduction: Comparing Wood Barrels and Food-Safe Plastic Fermentation Bags

Wood barrels and food-safe plastic fermentation bags each offer unique benefits and challenges for fermenting processes. Choosing between them depends on factors like flavor impact, ease of use, and sanitation requirements.

- Wood barrels retain natural microbes - They contribute complex, nuanced flavors to fermented products through micro-oxygenation and microbial activity.

- Plastic bags provide a neutral environment - Food-safe plastic bags do not impart additional flavors, ensuring the purity of the fermentation.

- Wood barrels require careful maintenance - Regular cleaning and sterilization prevent contamination and preserve barrel integrity during fermentation.

Plastic fermentation bags are lightweight, cost-effective, and simplify the cleaning process compared to traditional wood barrels.

Material Composition and Food Safety

Which material offers better food safety for fermenting: wood barrels or food-safe plastic fermentation bags? Wood barrels are made from natural hardwoods like oak, providing a porous environment that can harbor beneficial microbes but require diligent cleaning to prevent contamination. Food-safe plastic fermentation bags are composed of BPA-free, non-reactive polymers that ensure a sterile environment, minimizing the risk of harmful bacterial growth during fermentation.

Flavor Development: Unique Characteristics

Wood barrels contribute complex flavors to fermentation through natural microflora and oxygen exchange, enhancing depth and richness in the final product. Food-safe plastic fermentation bags offer a neutral environment that prevents flavor alterations, preserving the original taste of the fermenting ingredients. The choice between wood and plastic significantly impacts the development of unique aromatic profiles and texture complexity in fermented foods.

Oxygen Permeability and Fermentation Control

Wood barrels allow micro-oxygenation due to their porous structure, which can enhance flavor complexity during fermentation, while food-safe plastic bags provide an airtight environment that minimizes oxygen exposure, maintaining consistent fermentation conditions. Oxygen permeability in wood barrels supports beneficial microbial activity and subtle oxidation, important for traditional fermentation styles, whereas plastic bags reduce the risk of contamination and spoilage by limiting oxygen ingress. Choosing between wood and plastic depends on desired fermentation control, with wood barrels offering nuanced flavor development and plastic bags ensuring precise anaerobic fermentation.

Impact on Texture and Aroma

Wood barrels enhance fermentation by allowing micro-oxygenation, which develops complex aromas and a richer texture in the final product. Food-safe plastic fermentation bags maintain a neutral environment, preserving the original flavors without imparting additional aromas.

Wood barrels contribute tannins and subtle woody notes, improving the depth and mouthfeel of fermented foods or beverages. Plastic bags prevent oxidation and contamination while retaining a consistent texture, but lack the ability to influence aroma complexity. Choosing between the two depends on the desired flavor profile and textural outcome.

Cleaning, Maintenance, and Reusability

Wood barrels require meticulous cleaning and regular maintenance to prevent mold and contamination, while food-safe plastic fermentation bags offer easier sanitation and quicker drying times. Reusability favors wood barrels for long-term use, though plastic bags provide convenient single or limited-use options.

- Cleaning - Wood barrels need thorough scrubbing and occasional steaming to maintain hygiene, whereas plastic bags can be wiped and sanitized more straightforwardly.

- Maintenance - Barrels demand periodic inspection for cracks and leaks, while plastic bags require less upkeep due to their disposable nature.

- Reusability - Wood barrels last for years with proper care, making them cost-effective over time, but plastic bags often have limited reuse cycles depending on material thickness.

Cost Efficiency and Accessibility

Wood barrels offer traditional aesthetics and natural fermentation benefits but come with higher initial costs and maintenance expenses, making them less accessible for beginners. Food-safe plastic fermentation bags provide a cost-effective alternative with lower upfront investment and easy replacement options, ideal for budget-conscious fermenters.

Plastic bags are lightweight, space-saving, and widely available, making fermentation more accessible to hobbyists and small-scale producers. Although less durable than wood barrels, their affordability and convenience contribute to sustained cost efficiency over time.

Space and Storage Considerations

Wood barrels require significant space due to their rigid structure and large footprint, making them less ideal for small or limited storage areas. These barrels also need proper humidity and temperature control to prevent drying or cracking, adding to storage complexity.

Food-safe plastic fermentation bags are compact and flexible, allowing them to be easily stored in tight spaces or stacked when not in use. Their lightweight design and disposability make them convenient for quick setup and efficient post-fermentation cleanup.

Sustainability and Environmental Impact

Wood barrels offer a traditional, biodegradable option for fermentation with a lower carbon footprint due to their natural materials and long lifespan. Food-safe plastic fermentation bags provide a lightweight, reusable alternative but raise concerns over plastic waste and microplastic pollution.

- Wood barrels are renewable and biodegradable - They decompose naturally and can be sourced sustainably from managed forests.

- Plastic fermentation bags reduce resource use in transport - Their light weight lowers emissions during shipping compared to heavy wooden barrels.

- Plastic bags contribute to landfill and microplastic issues - Despite reusability, eventual disposal can harm ecosystems and water sources.

Related Important Terms

Oxygen Permeability Differential

Wood barrels offer moderate oxygen permeability that can enhance flavor complexity and microbial activity during fermentation, while food-safe plastic fermentation bags provide near-airtight conditions with minimal oxygen exposure, preserving fresh and clean fermentation profiles. The choice between them depends on desired oxygen interaction levels, with wood supporting subtle aerobic fermentation and plastic limiting oxidation risk for more controlled anaerobic environments.

Microbial-Tannin Dynamics

Wood barrels enhance microbial-tannin dynamics during fermentation by providing natural micro-oxygenation and complex tannin compounds that promote diverse microbial ecology and flavor complexity. Food-safe plastic fermentation bags offer inert environments that limit tannin interaction, resulting in a more controlled but less dynamic microbial fermentation process.

Barrel Aging Terroir Effect

Wood barrels impart unique terroir characteristics to fermented products due to micro-oxygenation and interaction with natural wood compounds, enhancing complexity and depth of flavor. Food-safe plastic fermentation bags offer a neutral environment that preserves the original taste without influencing fermentation through barrel aging terroir effects.

Polyethylene Leaching Index

Wood barrels provide natural micro-oxygenation but may cause inconsistent fermentation environments, whereas food-safe plastic fermentation bags, particularly those made from high-density polyethylene (HDPE), offer a controlled environment with a low Polyethylene Leaching Index (PLI), minimizing chemical leachates into the ferment. The Polyethylene Leaching Index is a critical factor in evaluating plastic bags, as lower PLI values indicate safer options for preserving the integrity and safety of fermented products.

Oak Lignin Infusion

Oak lignin infusion in wood barrels enhances fermentation by imparting complex flavors and natural antioxidants, enriching the final product's taste profile. Food-safe plastic fermentation bags lack this lignin content, resulting in a cleaner fermentation environment but without the unique flavor development associated with oak barrels.

Plastic-Bag Anaerobic Stability

Food-safe plastic fermentation bags provide superior anaerobic stability by creating an airtight environment that minimizes oxygen exposure, which is critical for preventing mold and ensuring consistent fermentation results. Unlike wood barrels, plastic bags do not absorb moisture or harbor bacteria in their surfaces, making them easier to sanitize and ideal for controlled, anaerobic fermenting processes.

Volatile Compound Retention

Wood barrels enhance volatile compound retention during fermentation by allowing micro-oxygenation and contributing natural tannins, which enrich flavor complexity and aroma profiles. Food-safe plastic fermentation bags provide a more inert environment, minimizing exposure to air but often resulting in less nuanced volatile compound development compared to wooden vessels.

Barrel Refilling Microflora

Wood barrels naturally harbor a diverse microflora that enhances fermentation complexity by promoting beneficial bacteria and yeast populations during refilling, creating unique flavor profiles. Food-safe plastic fermentation bags lack this microbial community, resulting in a more neutral fermentation environment without the bioactive contribution from barrel seasoning.

Flexi-Ferment Bagging

Wood barrels provide natural micro-oxygenation and complex flavor development during fermenting, while food-safe plastic fermentation bags like Flexi-Ferment Bags offer lightweight, flexible, and easy-to-clean alternatives that prevent contamination and maintain airtight environments. Flexi-Ferment Bags optimize fermentation by enabling space-saving storage and convenient handling, ideal for small batches and home fermenters seeking controlled anaerobic conditions.

Wood barrel vs food-safe plastic fermentation bag for fermenting. Infographic

cookingdiff.com

cookingdiff.com