Aluminum pans heat up quickly and distribute heat evenly, making them suitable for frying tasks that require consistent temperature control. Graphene pans offer superior non-stick properties and enhanced durability, reducing the need for excessive oil and providing easier cleanup after frying. Choosing between the two depends on prioritizing rapid heat conduction or long-term performance and health benefits during frying.

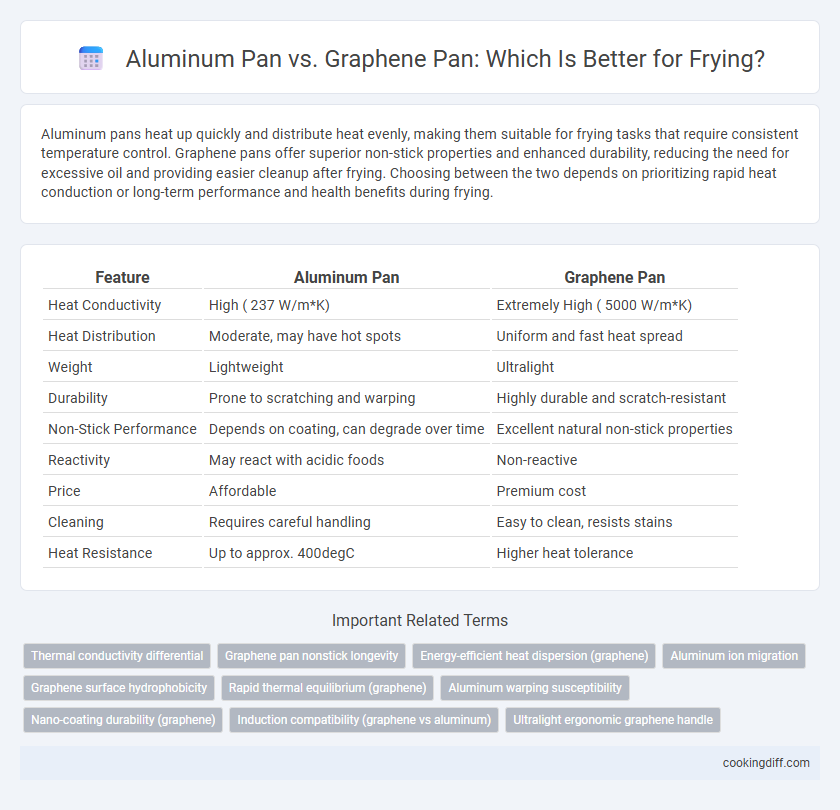

Table of Comparison

| Feature | Aluminum Pan | Graphene Pan |

|---|---|---|

| Heat Conductivity | High ( 237 W/m*K) | Extremely High ( 5000 W/m*K) |

| Heat Distribution | Moderate, may have hot spots | Uniform and fast heat spread |

| Weight | Lightweight | Ultralight |

| Durability | Prone to scratching and warping | Highly durable and scratch-resistant |

| Non-Stick Performance | Depends on coating, can degrade over time | Excellent natural non-stick properties |

| Reactivity | May react with acidic foods | Non-reactive |

| Price | Affordable | Premium cost |

| Cleaning | Requires careful handling | Easy to clean, resists stains |

| Heat Resistance | Up to approx. 400degC | Higher heat tolerance |

Aluminum Pan vs Graphene Pan: Frying Performance Compared

Aluminum pans heat up quickly and distribute heat evenly, making them popular for consistent frying results. Graphene pans offer superior thermal conductivity and durability, allowing for faster cooking times and enhanced non-stick properties. Choosing between aluminum and graphene depends on preferences for heat efficiency and long-term performance in frying.

Heat Conductivity: Aluminum versus Graphene Pans

Aluminum pans are widely used for frying due to their excellent heat conductivity, typically around 237 W/m*K, allowing for even cooking. Graphene pans, with thermal conductivity exceeding 5000 W/m*K, offer superior heat distribution and faster temperature adjustments compared to traditional aluminum cookware.

- Aluminum's Heat Conductivity - Aluminum pans provide consistent heat transfer, ensuring even frying without hot spots.

- Graphene's Superior Conductivity - Graphene's extremely high thermal conductivity allows rapid heating and cooling, enhancing cooking precision.

- Performance Impact - Faster heat response in graphene pans reduces cooking time and improves energy efficiency during frying.

Durability and Longevity in Frying Pans: Aluminum or Graphene?

Which frying pan offers better durability and longevity, aluminum or graphene? Graphene pans exhibit exceptional strength and resistance to warping, making them highly durable for extended frying use. Aluminum pans, while lightweight and heat-conductive, tend to warp and degrade faster under high heat and frequent use.

Nonstick Properties: Which Pan Wins for Frying?

Aluminum pans typically feature a nonstick coating that provides moderate release properties but may degrade under high heat, impacting frying performance. Graphene pans leverage advanced nanotechnology to offer superior nonstick surfaces with exceptional heat conductivity, enhancing food release and durability during frying.

Graphene's nonstick effectiveness reduces the need for excessive oil, promoting healthier frying and easier cleanup compared to traditional aluminum pans. While aluminum pans remain popular for affordability, graphene pans lead in nonstick performance, longevity, and consistent frying results.

Cooking Results: Frying Quality in Aluminum and Graphene Pans

| Aluminum Pan | Offers rapid and even heat distribution but may develop hot spots affecting frying consistency. Typically results in moderate non-stick performance, requiring more oil to prevent food sticking. Durability can be impacted by high heat leading to warping over time. |

| Graphene Pan | Exhibits superior heat conductivity enhancing uniform frying temperatures and reducing cooking time. Provides excellent non-stick properties with minimal oil usage, improving texture and flavor retention of fried foods. High durability resists warping and maintains frying quality over extended use. |

Maintenance and Cleaning: Aluminum vs Graphene Frying Pans

Aluminum frying pans require regular seasoning and can warp or discolor with improper cleaning methods, such as using abrasive scrubbers. Graphene pans offer a non-stick surface that resists sticking and staining, making them easier to clean without harsh chemicals.

Aluminum pans may accumulate residues that need careful removal to prevent damage, while graphene pans are more resistant to corrosion and scratches. Cleaning aluminum pans often involves handwashing to maintain their integrity, compared to the dishwasher-safe nature of many graphene pans. The durability and smoothness of graphene surfaces reduce maintenance frequency, providing a more convenient cooking experience over time.

Price Comparison: Aluminum Pan vs Graphene Pan for Frying

Aluminum pans are significantly more affordable, with prices typically ranging from $15 to $40, making them a budget-friendly option for everyday frying. In contrast, graphene pans command a premium price, often costing between $80 and $150 due to advanced material technology and superior heat conductivity.

The long-term investment in a graphene pan can justify its higher initial cost by offering enhanced durability and faster, more even cooking performance. While aluminum pans may require frequent replacement due to warping or coating degradation, graphene pans provide greater longevity and resistance to wear.

Safety and Reactivity: Frying with Aluminum or Graphene

Graphene pans offer enhanced chemical stability and reduced reactivity compared to traditional aluminum pans, which can leach metals into food when overheated. Safety concerns with aluminum arise from its potential to interact with acidic or alkaline foods, unlike graphene, which remains inert under high frying temperatures.

- Graphene Chemical Stability - Graphene is highly resistant to chemical reactions, preventing contamination during frying.

- Aluminum Reactivity - Aluminum can react with acidic or alkaline ingredients, potentially affecting food safety and flavor.

- Health Implications - Graphene's inert nature minimizes risks of metal leaching, promoting safer cooking conditions.

Weight and Handling: Ergonomics of Aluminum vs Graphene Pans

Aluminum pans are generally lightweight, providing ease of maneuverability during frying, while graphene pans offer exceptional strength with minimal weight, enhancing handling comfort. The ergonomic design of graphene pans reduces wrist strain compared to traditional aluminum cookware due to their slimmer yet robust construction.

- Aluminum's Lightweight Nature - Weighing around 1-2 pounds, aluminum pans are easy to lift and control, making them user-friendly for everyday frying tasks.

- Graphene's Strength-to-Weight Ratio - Despite their ultra-lightweight design, graphene pans maintain superior durability, allowing for effortless handling over prolonged cooking sessions.

- Ergonomic Impact - The balanced weight distribution in graphene pans minimizes hand fatigue, improving overall cooking precision and safety.

Choosing between aluminum and graphene pans for frying hinges on weight preferences and ergonomic benefits tailored to individual cooking styles.

Related Important Terms

Thermal conductivity differential

Graphene pans possess significantly higher thermal conductivity--approximately 5000 W/m*K--compared to aluminum pans, which typically range around 205 W/m*K, allowing for faster and more even heat distribution during frying. This superior thermal conductivity of graphene ensures precise temperature control and reduced hotspots, enhancing cooking performance and food quality.

Graphene pan nonstick longevity

Graphene pans offer superior nonstick longevity compared to aluminum pans due to their enhanced durability and resistance to scratching and wear, maintaining a smooth cooking surface over extended use. The advanced thermal conductivity of graphene also ensures even heating, reducing hotspots that typically degrade nonstick coatings in aluminum pans.

Energy-efficient heat dispersion (graphene)

Graphene pans offer superior energy-efficient heat dispersion compared to aluminum pans, ensuring even cooking with less energy consumption. This advanced thermal conductivity reduces hot spots and maintains consistent frying temperatures, optimizing fuel usage and enhancing cooking performance.

Aluminum ion migration

Aluminum pans pose a risk of aluminum ion migration into food during frying, which can raise health concerns due to potential toxicity. Graphene pans, with their inert and highly stable surface, effectively prevent metal ion migration, ensuring safer frying and better food quality.

Graphene surface hydrophobicity

Graphene pans exhibit superior hydrophobicity due to their unique carbon lattice structure, which minimizes oil absorption and enhances non-stick performance compared to traditional aluminum pans. This hydrophobic surface significantly reduces food residue buildup, improving frying efficiency and ease of cleaning.

Rapid thermal equilibrium (graphene)

Graphene pans achieve rapid thermal equilibrium due to graphene's exceptional thermal conductivity, allowing even heat distribution and quicker temperature stabilization compared to aluminum pans. This efficiency reduces cooking times and minimizes hot spots, enhancing frying performance and food quality.

Aluminum warping susceptibility

Aluminum pans tend to warp easily under high heat due to their lower melting point and softer metal structure, which can lead to uneven cooking surfaces and reduced pan lifespan. In contrast, graphene pans offer superior thermal stability and resistance to warping, maintaining consistent heat distribution even at elevated frying temperatures.

Nano-coating durability (graphene)

Graphene pans exhibit superior nano-coating durability compared to aluminum pans, resisting scratches and wear over prolonged frying sessions while maintaining optimal heat conduction. The robust graphene layer prevents surface degradation, ensuring enhanced longevity and consistent cooking performance in high-temperature frying environments.

Induction compatibility (graphene vs aluminum)

Graphene pans exhibit superior induction compatibility due to their excellent electrical conductivity and magnetic properties, enabling efficient heat transfer and uniform cooking. In contrast, aluminum pans typically require a magnetic base or induction plate since pure aluminum is non-magnetic and less effective on induction cooktops.

Aluminum pan vs graphene pan for frying. Infographic

cookingdiff.com

cookingdiff.com