Traditional frying uses high temperatures that often result in oil absorption and nutrient loss, leading to greasier, less healthy snacks. Vacuum frying operates under reduced pressure, allowing frying at lower temperatures which preserves natural flavors and nutrients while producing crisp, less oily snacks. This method also minimizes the formation of harmful compounds, making vacuum-fried snacks a healthier alternative to traditional fried options.

Table of Comparison

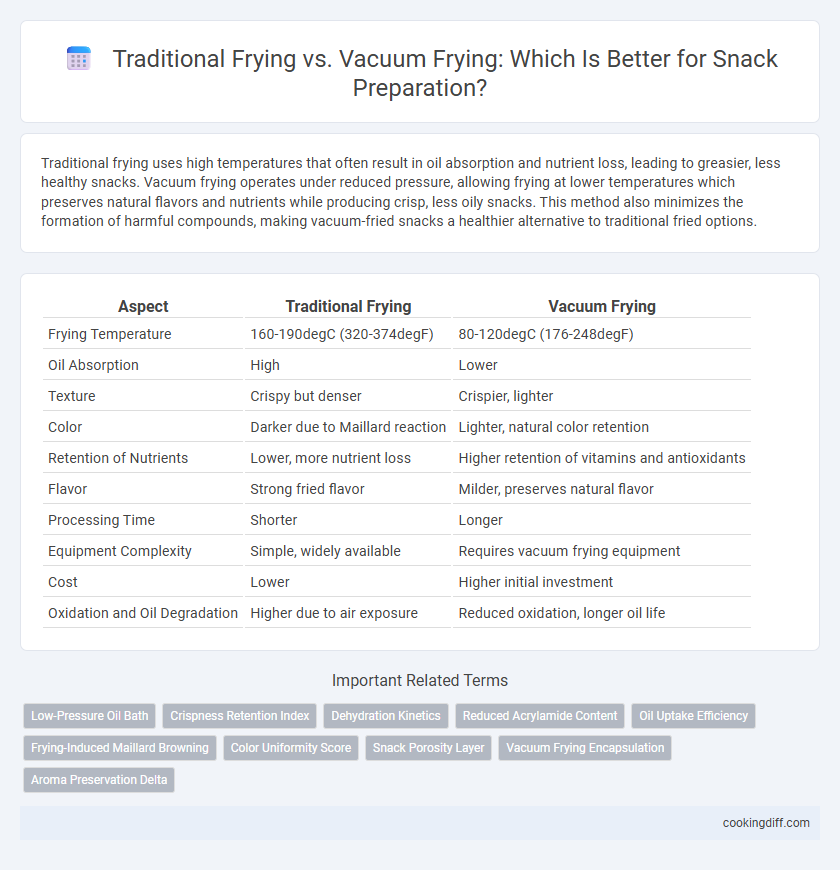

| Aspect | Traditional Frying | Vacuum Frying |

|---|---|---|

| Frying Temperature | 160-190degC (320-374degF) | 80-120degC (176-248degF) |

| Oil Absorption | High | Lower |

| Texture | Crispy but denser | Crispier, lighter |

| Color | Darker due to Maillard reaction | Lighter, natural color retention |

| Retention of Nutrients | Lower, more nutrient loss | Higher retention of vitamins and antioxidants |

| Flavor | Strong fried flavor | Milder, preserves natural flavor |

| Processing Time | Shorter | Longer |

| Equipment Complexity | Simple, widely available | Requires vacuum frying equipment |

| Cost | Lower | Higher initial investment |

| Oxidation and Oil Degradation | Higher due to air exposure | Reduced oxidation, longer oil life |

Introduction to Frying Methods for Snacks

Frying is a popular cooking technique widely used to produce crispy and flavorful snacks. Traditional frying involves high-temperature oil immersion, whereas vacuum frying uses reduced pressure and lower temperatures to preserve food quality.

- Traditional frying - Involves cooking snacks at temperatures typically between 160-190degC, resulting in familiar textures and flavors but higher oil absorption.

- Vacuum frying - Utilizes lower temperatures around 90-120degC under vacuum conditions, reducing oxidation and preserving nutrients and natural colors.

- Quality impact - Vacuum frying often yields healthier, less greasy snacks with enhanced sensory attributes compared to conventional frying methods.

What is Traditional Frying?

Traditional frying involves cooking snacks in hot oil at atmospheric pressure, typically between 160-190degC. This method results in a crispy texture but often leads to higher oil absorption and nutrient loss.

- High Temperature - Snacks are fried at standard high temperatures causing Maillard browning and crispy texture.

- Oil Absorption - Traditional frying leads to significant oil uptake, increasing calorie content.

- Nutrient Retention - Heat exposure during frying can degrade heat-sensitive vitamins.

Traditional frying remains popular for its flavor and texture despite some nutritional drawbacks.

Understanding Vacuum Frying Technology

How does vacuum frying technology differ from traditional frying methods in snack production? Vacuum frying operates at lower temperatures and reduced pressure, which preserves nutrients and maintains the natural color and flavor of snacks. This method also significantly reduces oil absorption, resulting in healthier, crispier products compared to conventional high-temperature frying.

Key Differences Between Traditional and Vacuum Frying

Traditional frying involves cooking snacks at atmospheric pressure with hot oil temperatures typically between 160degC and 190degC, leading to faster cooking times but higher oil absorption and potential nutrient loss. Vacuum frying operates under reduced pressure, allowing frying at lower temperatures around 80degC to 120degC, which preserves color, flavor, and nutrients while reducing harmful compounds like acrylamide.

Vacuum frying produces snacks with a crisp texture and less oil content compared to traditional frying's denser, greasier results. The lower temperature and oxygen-free environment in vacuum frying minimizes oxidation and degradation of sensitive ingredients, making it ideal for premium snack products.

Impact on Snack Texture and Crispiness

Traditional frying exposes snacks to high temperatures, quickly evaporating moisture and creating a crispy outer layer with a dense, crunchy texture. However, this method can also lead to uneven cooking and oil absorption, impacting the overall crispiness and sometimes resulting in greasiness.

Vacuum frying operates at lower temperatures under reduced pressure, preserving the snack's natural moisture and color while producing a lighter, airier texture. This technique minimizes oil uptake and enhances uniform crispiness, making snacks more appealing in texture and maintaining quality longer.

Oil Absorption: Traditional vs Vacuum Frying

Vacuum frying significantly reduces oil absorption in snacks compared to traditional frying, resulting in lower fat content. This method preserves the natural flavors and nutrients while producing a crisp texture with less oil.

- Traditional frying involves higher temperatures - This causes more oil to penetrate the snack, increasing overall fat content.

- Vacuum frying operates under reduced pressure - It lowers the boiling point of oil, minimizing oil uptake during the frying process.

- Oil absorption impacts snack quality - Vacuum frying yields healthier snacks with extended shelf life due to reduced oil content.

Nutritional Value Comparison

Traditional frying of snacks typically results in higher oil absorption, increasing calorie content and reducing overall nutritional value. Vacuum frying, performed at lower temperatures and reduced pressure, preserves more nutrients such as vitamins and antioxidants while minimizing oil uptake. Studies indicate vacuum-fried snacks maintain better texture and flavor with improved health benefits compared to conventional frying methods.

Flavor Retention and Color Preservation

| Frying Method | Flavor Retention | Color Preservation |

|---|---|---|

| Traditional Frying | High heat exposure often degrades delicate flavors, resulting in less natural taste retention. | Intense temperatures cause enzymatic browning and Maillard reactions, leading to darker, less vibrant colors. |

| Vacuum Frying | Lower temperatures under reduced pressure better retain natural flavors by minimizing oxidation. | Vacuum environment limits oxygen exposure, preserving brighter, more natural snack colors. |

Cost and Efficiency Considerations

Traditional frying typically incurs lower initial equipment costs but demands higher ongoing expenses due to increased oil usage and energy consumption. Vacuum frying, although involving significant upfront investment, reduces oil absorption and energy costs, enhancing long-term efficiency.

Cost efficiency in vacuum frying derives from lower frying temperatures and reduced oil degradation, extending oil life and reducing waste disposal expenses. Traditional frying offers faster processing times, but vacuum frying ensures better preservation of nutritional quality, potentially justifying higher costs. Manufacturers must balance these factors based on production scale and product quality requirements.

Related Important Terms

Low-Pressure Oil Bath

Low-pressure oil bath in vacuum frying reduces the boiling point of water in snacks, preserving nutrients and maintaining texture while minimizing oil absorption. Traditional frying exposes snacks to higher temperatures and atmospheric pressure, leading to nutrient loss and increased oil uptake.

Crispness Retention Index

Vacuum frying preserves snack crispness more effectively by reducing oil absorption and moisture loss, resulting in a higher Crispness Retention Index compared to traditional frying. Traditional frying often causes greater texture degradation due to higher temperatures and oxidative reactions that compromise snack crispness over time.

Dehydration Kinetics

Traditional frying involves high temperatures that cause rapid moisture loss and surface dehydration, leading to uneven drying and potential quality degradation in snacks. Vacuum frying operates under reduced pressure, lowering the boiling point of water and enabling slower, more uniform dehydration kinetics that preserve texture, color, and nutritional value.

Reduced Acrylamide Content

Vacuum frying significantly reduces acrylamide formation in snacks by lowering the frying temperature and oxygen exposure compared to traditional frying methods. This process preserves flavor and texture while enhancing food safety through minimized harmful compound production.

Oil Uptake Efficiency

Traditional frying methods result in higher oil uptake due to exposure to atmospheric pressure, leading to greasier snacks with increased calorie content. Vacuum frying reduces oil absorption by frying under reduced pressure, producing healthier, lower-fat snacks while preserving texture and flavor.

Frying-Induced Maillard Browning

Traditional frying induces Maillard browning through high-temperature oil immersion, causing substantial flavor development but often resulting in uneven color and nutrient loss. Vacuum frying operates under reduced pressure and lower temperatures, enhancing Maillard reaction control for consistent browning, improved flavor retention, and better preservation of nutritional quality in snacks.

Color Uniformity Score

Traditional frying often results in inconsistent color uniformity scores due to uneven heat distribution and prolonged exposure to high temperatures, causing darker spots and browning variations. Vacuum frying enhances color uniformity scores by reducing oxidation and heat damage, producing evenly colored snacks with a lighter, more appealing appearance.

Snack Porosity Layer

Traditional frying creates a highly porous snack surface due to rapid moisture evaporation and oil absorption, resulting in a crispy texture but increased oil content. Vacuum frying reduces porosity by frying at lower temperatures and reduced pressure, preserving snack structure and reducing oil uptake for a healthier, less greasy product.

Vacuum Frying Encapsulation

Vacuum frying preserves the nutritional quality and natural flavors of snacks by frying at lower temperatures under reduced pressure, which minimizes oil absorption and acrylamide formation. This method enhances the encapsulation of volatile compounds, resulting in a crisp texture and richer taste compared to traditional frying.

Traditional frying vs vacuum frying for snacks. Infographic

cookingdiff.com

cookingdiff.com