Traditional woks, often made from carbon steel, provide superior heat retention and even distribution, making them ideal for high-heat frying and quick stir-frying tasks. Spun steel woks, while lighter and easier to handle, typically heat less evenly and may require more attention to prevent sticking or burning. Choosing between these depends on cooking style and preference, with traditional woks favored for their durability and performance in intense frying applications.

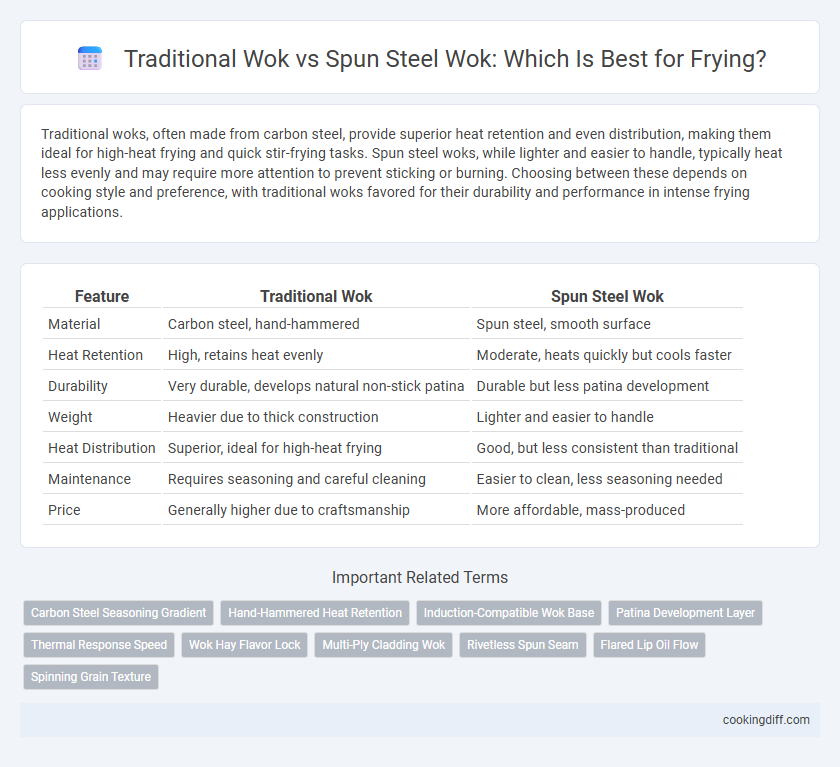

Table of Comparison

| Feature | Traditional Wok | Spun Steel Wok |

|---|---|---|

| Material | Carbon steel, hand-hammered | Spun steel, smooth surface |

| Heat Retention | High, retains heat evenly | Moderate, heats quickly but cools faster |

| Durability | Very durable, develops natural non-stick patina | Durable but less patina development |

| Weight | Heavier due to thick construction | Lighter and easier to handle |

| Heat Distribution | Superior, ideal for high-heat frying | Good, but less consistent than traditional |

| Maintenance | Requires seasoning and careful cleaning | Easier to clean, less seasoning needed |

| Price | Generally higher due to craftsmanship | More affordable, mass-produced |

Understanding Traditional Woks in Frying

Traditional woks, often made from carbon steel, are revered for their excellent heat retention and ability to develop a natural non-stick surface through seasoning. These woks provide superior high-heat frying performance essential for authentic stir-fry dishes.

- Material Composition - Carbon steel construction ensures quick and even heating for optimal frying results.

- Seasoning Requirement - Requires regular seasoning to build a protective patina that enhances flavor and prevents rust.

- Heat Distribution - Offers superior heat concentration at the bottom, enabling fast, high-temperature cooking critical for traditional frying techniques.

What Makes Spun Steel Woks Unique

Spun steel woks are crafted by spinning a flat steel disc at high speeds, creating a seamless, lightweight, and highly responsive cooking surface ideal for precise temperature control during frying. Their thinner metal construction heats up and cools down faster than traditional woks, promoting even cooking and reducing the risk of burning food. Unlike cast iron or carbon steel woks, spun steel woks offer exceptional durability without warping, making them uniquely suited for high-heat stir-frying techniques.

Heat Distribution: Traditional vs Spun Steel

Traditional woks, often made from carbon steel or cast iron, provide excellent heat retention but may heat unevenly across the surface. Spun steel woks offer superior heat distribution due to their uniform thickness, ensuring consistent frying temperatures.

- Traditional wok heat retention - Thick materials like cast iron hold heat well but can cause hot spots during frying.

- Spun steel wok uniformity - Crafted by spinning, spun steel woks have even thickness, leading to balanced heat spread.

- Frying performance - Even heat distribution in spun steel woks reduces the risk of food burning or undercooking.

Choosing between traditional and spun steel woks depends on the desired balance between heat retention and consistent heat distribution for frying.

Nonstick Qualities in Both Wok Types

How do the nonstick qualities of traditional woks compare to spun steel woks when frying? Traditional woks, typically made from carbon steel, develop a natural nonstick patina over time through seasoning, enhancing their performance in high-heat frying. Spun steel woks, while also capable of seasoning, usually have a smoother surface that allows for quicker food release but may require more frequent maintenance to maintain their nonstick properties.

Durability: Comparing Traditional and Spun Steel Woks

Traditional woks, often made from carbon steel, offer excellent heat retention but are prone to rust and require regular seasoning to maintain durability. Spun steel woks provide a more uniform thickness and are typically thicker, enhancing resistance to warping and physical damage during intense frying.

Durability in traditional woks depends heavily on user maintenance, with potential for rust and deformation if neglected. Spun steel woks, benefiting from a sturdier build, withstand high heat and heavy use more reliably over time. Their enhanced structural integrity makes spun steel a preferable choice for those seeking long-lasting frying tools.

Weight and Handling During Frying

Traditional woks are typically heavier due to their thicker carbon steel or cast iron construction, which can provide better heat retention but makes them more challenging to maneuver during frying. The added weight helps distribute heat evenly, crucial for stir-frying, yet requires more strength and skill to toss ingredients efficiently.

Spun steel woks are lighter with a thinner metal body, allowing for more agile handling and quicker frying movements, ideal for fast-paced cooking. Their reduced weight makes tossing and stirring ingredients easier, although they may have less heat retention compared to traditional heavier woks.

Seasoning Requirements for Each Wok

Traditional woks require thorough seasoning to build a natural non-stick surface and prevent rusting, while spun steel woks often need less intensive seasoning due to their smoother finish. Proper seasoning enhances flavor retention and cooking performance in both types of woks.

- Traditional Wok absorbs oil deeply - This requires multiple seasoning layers to develop a durable patina that improves non-stick properties over time.

- Spun Steel Wok has a polished surface - It forms an effective seasoning layer more quickly and resists rust with less maintenance.

- Consistent use and oiling - Both woks benefit from regular heat and oil application to maintain seasoning and enhance frying results.

Frying Performance: Which Wok Excels?

| Wok Type | Heat Conductivity | Durability | Frying Performance |

|---|---|---|---|

| Traditional Wok | Excellent heat retention and rapid heat distribution | High, with proper seasoning and care | Provides superior searing and even cooking, ideal for authentic stir-frying |

| Spun Steel Wok | Good heat conduction but less consistent than traditional carbon steel | Moderate, may warp under high heat without thick gauge | Suitable for frying with quicker heating time but may sacrifice some flavor depth |

Maintenance and Cleaning Considerations

Traditional carbon steel woks require regular seasoning to maintain a non-stick surface and prevent rust, making their maintenance essential for frying tasks. Spun steel woks often come pre-seasoned and need less frequent upkeep but may lack the durability of carbon steel under high heat. Cleaning both wok types involves avoiding harsh detergents; instead, use hot water and a soft brush to preserve the seasoning layer.

Related Important Terms

Carbon Steel Seasoning Gradient

Traditional wok offers a natural carbon steel seasoning gradient that improves non-stick properties and enhances flavor absorption over time, making it ideal for high-heat frying techniques. Spun steel woks, while faster to heat, lack the gradual seasoning buildup found in forged carbon steel woks, resulting in less effective seasoning layers and reduced frying performance.

Hand-Hammered Heat Retention

Traditional hand-hammered woks excel in heat retention due to their thicker carbon steel construction and textured surface that distributes heat evenly for superior frying performance. In contrast, spun steel woks, being thinner and smoother, heat up quickly but lose temperature faster, making them less ideal for consistent high-heat frying techniques.

Induction-Compatible Wok Base

A traditional wok made from carbon steel offers excellent heat retention and quick temperature changes ideal for frying, but it often lacks induction compatibility due to its rounded bottom. Spun steel woks are designed with a flat, induction-compatible base, ensuring even heat distribution on induction cooktops while maintaining the wok's high heat capacity essential for stir-frying.

Patina Development Layer

Traditional wok develops a rich patina layer over time that enhances non-stick properties and deepens flavor through continuous seasoning during frying. In contrast, spun steel wok forms a thinner, less durable patina that may require more frequent seasoning to maintain optimal frying performance and heat distribution.

Thermal Response Speed

Traditional woks made from carbon steel provide excellent thermal response speed due to their thin, lightweight construction, allowing rapid heating and precise temperature control during frying. In contrast, spun steel woks have a slightly slower thermal response because of their thicker material, which retains heat longer but may delay quick temperature adjustments.

Wok Hay Flavor Lock

Traditional woks, often made of carbon steel, develop a distinctive seasoning known as "wok hay," a smoky, fragrant flavor essential for authentic stir-frying. Spun steel woks, though lighter and quicker to heat, typically lack the porous surface needed to build wok hay, resulting in less depth of flavor during frying.

Multi-Ply Cladding Wok

Multi-ply cladding woks combine layers of stainless steel and aluminum for superior heat distribution and durability during high-heat frying, outperforming traditional single-material woks. This construction ensures even cooking and prevents hotspots, making it ideal for stir-frying and quick searing compared to traditional cast iron or spun steel woks.

Rivetless Spun Seam

Rivetless spun steel woks offer superior heat distribution and durability compared to traditional riveted woks, eliminating hot spots common in the latter. The seamless construction prevents food buildup and simplifies cleaning, enhancing frying efficiency and hygiene.

Flared Lip Oil Flow

The traditional wok's pronounced flared lip enhances oil flow, promoting even heat distribution and efficient tossing during frying. In contrast, the spun steel wok features a subtler lip curve, which may cause oil to pool and reduce the effectiveness of high-heat stir-frying techniques.

Traditional Wok vs Spun Steel Wok for Frying Infographic

cookingdiff.com

cookingdiff.com