Grilling offers a traditional cooking method using open flames that provide intense direct heat, ideal for searing and developing complex flavors. Infrared grilling achieves even higher temperatures through radiant heat, delivering faster cooking times and more consistent heat distribution. Both methods excel in producing a smoky char, but infrared grilling reduces flare-ups and heat fluctuations, enhancing precision.

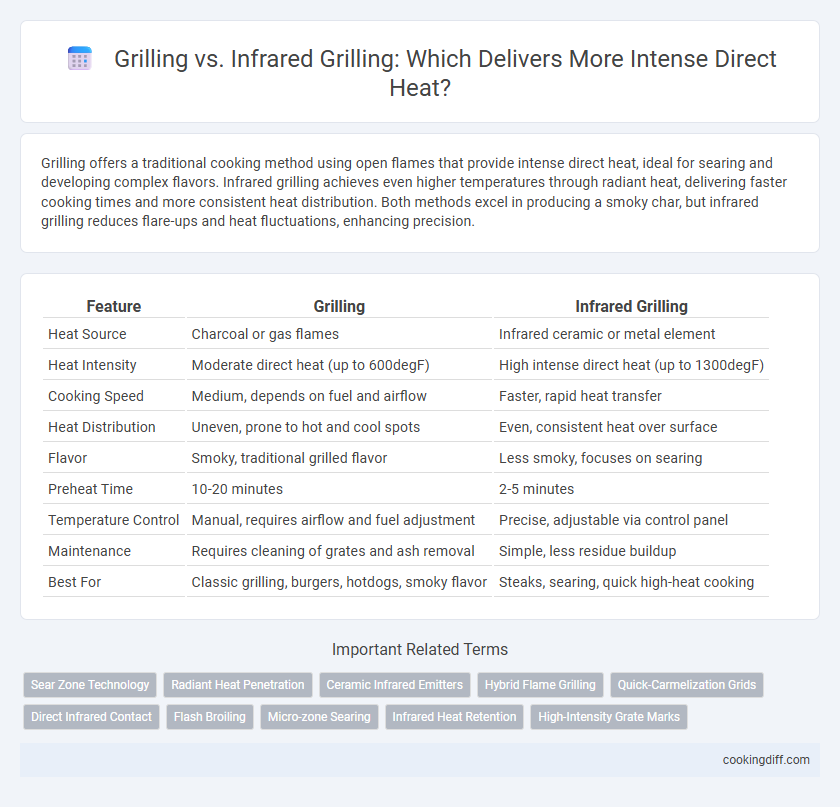

Table of Comparison

| Feature | Grilling | Infrared Grilling |

|---|---|---|

| Heat Source | Charcoal or gas flames | Infrared ceramic or metal element |

| Heat Intensity | Moderate direct heat (up to 600degF) | High intense direct heat (up to 1300degF) |

| Cooking Speed | Medium, depends on fuel and airflow | Faster, rapid heat transfer |

| Heat Distribution | Uneven, prone to hot and cool spots | Even, consistent heat over surface |

| Flavor | Smoky, traditional grilled flavor | Less smoky, focuses on searing |

| Preheat Time | 10-20 minutes | 2-5 minutes |

| Temperature Control | Manual, requires airflow and fuel adjustment | Precise, adjustable via control panel |

| Maintenance | Requires cleaning of grates and ash removal | Simple, less residue buildup |

| Best For | Classic grilling, burgers, hotdogs, smoky flavor | Steaks, searing, quick high-heat cooking |

Introduction to Grilling and Infrared Grilling

What distinguishes traditional grilling from infrared grilling in delivering intense direct heat? Traditional grilling uses open flames or hot coals to cook food, producing a classic smoky flavor and char marks. Infrared grilling employs radiant heat technology, generating higher temperatures more quickly and evenly, resulting in faster searing and juicier, tender food.

How Traditional Grilling Delivers Direct Heat

Traditional grilling delivers intense direct heat through open flames that radiate upward, searing food quickly and imparting a smoky flavor. Heat distribution depends on the type of fuel and grill design, allowing for precise control over cooking intensity.

- Direct contact with flames - Charcoal or gas flames provide high temperatures that sear the surface of the food, creating a crispy crust.

- Heat convection and radiation - Heat rises and radiates evenly around the food, ensuring thorough cooking.

- Flavor enhancement - Combustion byproducts like smoke infuse grilled items with distinctive, robust flavors.

The Science Behind Infrared Grilling Technology

Infrared grilling technology utilizes electromagnetic waves to generate intense direct heat, reaching temperatures up to 1800degF rapidly. This method transfers heat more efficiently than traditional grilling by heating the cooking surface directly rather than relying on convection.

The science behind infrared grilling involves the emission of infrared radiation that excites food molecules, causing rapid searing and caramelization. This process locks in juices while producing evenly cooked meat with a distinctive char and flavor. Traditional grills use radiant heat from flames or hot coals, which can result in uneven cooking and longer preheating times compared to infrared grills.

Intensity of Heat: Grilling vs Infrared Grilling

Traditional grilling uses gas or charcoal to provide heat that typically ranges between 400degF and 600degF, delivering consistent direct heat suitable for searing and cooking various foods. Infrared grilling generates temperatures exceeding 1,000degF by emitting radiant heat, resulting in faster cooking times and more intense searing effects.

The intense heat from infrared grills allows for a crispier exterior while locking in juiciness, making it ideal for steaks and thick cuts of meat. Grilling with conventional methods offers versatile temperature control but generally lacks the extreme heat concentration found in infrared grilling.

Heat Distribution: Which Method Is More Even?

Infrared grilling provides more even heat distribution by using radiant heat that directly heats the food's surface, reducing hot and cold spots common in traditional grilling. Traditional grilling relies on convection and conduction, often causing uneven heat zones due to grill grate placement and charcoal or burner layout. Infrared grills maintain consistent high temperatures across the cooking surface, ensuring uniform cooking and searing for intense direct heat applications.

Flavor Differences: Does Infrared Alter Taste?

Infrared grilling uses intense direct heat that sears food quickly, locking in juices and enhancing natural flavors without creating excessive smoke. Traditional grilling imparts a smoky taste from charcoal or wood, which can alter the flavor profile but may take longer to cook.

- Infrared Grilling Produces a Cleaner Flavor - The high heat sears food rapidly, preserving its innate taste without overwhelming smokiness.

- Traditional Grilling Adds Smoky Notes - Charcoal or wood fuels release aromatic compounds that infuse the food with distinctive, complex flavors.

- Flavor Intensity Varies by Heat Source - Infrared's focused heat intensifies searing while traditional grills balance smoke and heat for layered taste profiles.

Cooking Speed: Comparing Time Efficiency

| Grilling | Traditional grilling uses convection heat which takes longer to reach high temperatures, typically requiring 10-15 minutes to preheat before cooking. It cooks foods steadily, often needing 8-12 minutes for direct heat searing. Ideal for a slow, controlled cooking process but less time-efficient. |

| Infrared Grilling | Infrared grilling delivers intense, direct radiant heat, heating up to 1000degF within 5 minutes or less. This rapid temperature build-up significantly reduces cooking time, often searing foods in 3-5 minutes. Superior for fast cooking and quick searing with high heat retention efficiency. |

Energy Efficiency and Fuel Consumption

Traditional grilling relies on convection heat, which often results in longer cooking times and higher fuel consumption. Infrared grilling uses radiant heat to deliver intense direct heat efficiently, reducing energy use significantly.

Infrared grills convert fuel to heat more effectively, making them up to 30% more energy-efficient than conventional grills. This efficiency lowers fuel costs and minimizes environmental impact while achieving optimal cooking performance.

Maintenance and Durability Concerns

Traditional grilling requires regular cleaning of grates and burners to prevent buildup and corrosion, while infrared grilling demands less frequent maintenance due to its ceramic or metal plates that resist grease and food residue. Durability varies as infrared grills often have components vulnerable to cracking under extreme heat, whereas conventional grills feature more resilient parts but may suffer from rust over time.

- Grate cleaning - Traditional grills need frequent scrubbing to maintain optimal heat transfer and hygiene.

- Infrared emitter durability - Infrared grills use emitter plates that can degrade or crack if not properly maintained.

- Rust resistance - Conventional grills are prone to rust, requiring protective coatings and regular inspection.

Choosing between grilling methods depends on balancing maintenance efforts with the expected lifespan of the grill components.

Related Important Terms

Sear Zone Technology

Sear Zone Technology in infrared grilling delivers intense direct heat by using high-powered ceramic burners that radiate consistent heat up to 1800degF, creating a superior sear compared to traditional grilling's uneven flame distribution. This technology enhances Maillard reaction efficiency, locking in juices and flavor through rapid surface caramelization.

Radiant Heat Penetration

Grilling using traditional methods relies on convective and conductive heat, whereas infrared grilling delivers intense radiant heat that penetrates food more efficiently, ensuring faster searing and moisture retention. Infrared radiant heat reaches deeper into the meat, producing juicier results with a more evenly cooked interior compared to standard grilling.

Ceramic Infrared Emitters

Ceramic infrared emitters in infrared grilling provide intense, direct heat by producing consistent radiant heat that penetrates food quickly, enhancing searing and lock-in juices compared to traditional grilling. Unlike conventional grills that rely on convective heat, ceramic infrared emitters reduce flare-ups and ensure even cooking temperatures for optimized grilling performance.

Hybrid Flame Grilling

Hybrid flame grilling combines traditional flame grilling and infrared technology to deliver intense direct heat with enhanced precision and faster cooking times. This method ensures even searing and better caramelization while reducing flare-ups commonly associated with conventional grilling.

Quick-Carmelization Grids

Quick-caramelization grids in infrared grilling deliver intense direct heat that rapidly sears meats, enhancing flavor and texture through faster Maillard reactions compared to traditional grilling. This method locks in juices and creates a crisp, caramelized crust with greater efficiency due to the concentrated heat emission of infrared grids.

Direct Infrared Contact

Infrared grilling utilizes intense direct infrared radiation to cook food faster and sear meats with superior precision compared to traditional grilling methods that rely on convection heat. Direct infrared contact achieves higher temperatures, promoting caramelization and a crisp exterior while retaining juiciness inside, making it ideal for steaks and burgers.

Flash Broiling

Flash broiling with infrared grilling delivers intense direct heat by using high-energy wavelengths that rapidly sear meat, locking in juices and creating a crisp crust. Traditional grilling relies on convection heat and flame, which can result in slower cooking and less consistent searing compared to the immediate, radiant heat of infrared technology.

Micro-zone Searing

Micro-zone searing using infrared grilling generates extreme direct heat levels surpassing traditional grilling methods, achieving rapid caramelization and a superior Maillard reaction on the meat's surface. This intense heat concentrates on a precise area, locking in juices and enhancing texture without overcooking the interior, optimizing flavor and tenderness.

Infrared Heat Retention

Infrared grilling excels in intense direct heat by using radiant energy to heat food quickly and evenly, enhancing caramelization and searing. Its superior heat retention is due to the infrared burners that maintain consistent high temperatures without flare-ups, optimizing cooking efficiency and flavor development.

Grilling vs Infrared Grilling for intense direct heat. Infographic

cookingdiff.com

cookingdiff.com