Defrosting in a microwave uses rapid heat to melt ice crystals, which can lead to uneven thawing and partial cooking of food, potentially affecting texture and taste. Blast chilling, on the other hand, gradually reduces the temperature of frozen food, preserving its quality and safety by minimizing bacterial growth and maintaining the original texture. Choosing blast chilling over microwave defrosting ensures more consistent thawing results, especially for delicate or large food items.

Table of Comparison

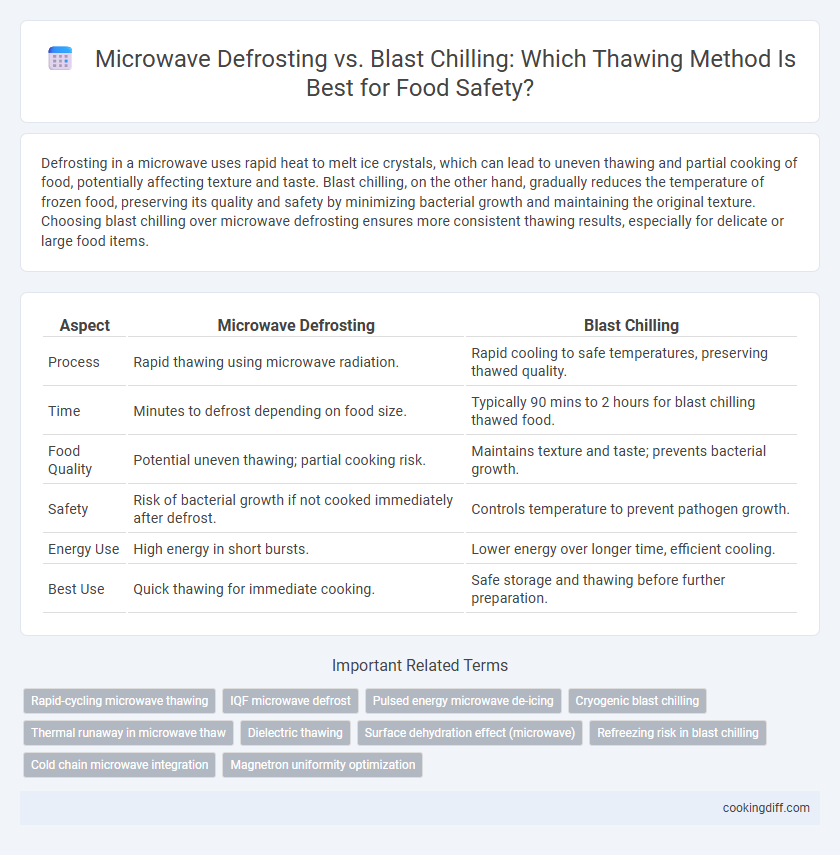

| Aspect | Microwave Defrosting | Blast Chilling |

|---|---|---|

| Process | Rapid thawing using microwave radiation. | Rapid cooling to safe temperatures, preserving thawed quality. |

| Time | Minutes to defrost depending on food size. | Typically 90 mins to 2 hours for blast chilling thawed food. |

| Food Quality | Potential uneven thawing; partial cooking risk. | Maintains texture and taste; prevents bacterial growth. |

| Safety | Risk of bacterial growth if not cooked immediately after defrost. | Controls temperature to prevent pathogen growth. |

| Energy Use | High energy in short bursts. | Lower energy over longer time, efficient cooling. |

| Best Use | Quick thawing for immediate cooking. | Safe storage and thawing before further preparation. |

Introduction to Food Thawing Methods

Microwaving defrosts food rapidly by using electromagnetic waves to excite water molecules, promoting quicker thawing times. Blast chilling, in contrast, employs extremely cold air to gradually lower food temperature, preserving texture and reducing bacterial growth. Choosing the appropriate thawing method depends on food type, safety considerations, and desired outcome.

How Microwave Defrosting Works

Microwave defrosting uses electromagnetic waves to agitate water molecules in food, rapidly generating heat and melting ice crystals. This method allows for quick thawing but can unevenly cook edges while the center remains frozen.

- Electromagnetic radiation - Microwaves emit waves at 2.45 GHz that target water molecules, causing friction and heat within the food.

- Selective heating - Heating focuses on water-rich areas, often resulting in inconsistent thawing and partial cooking of outer layers.

- Time efficiency - Microwave defrosting significantly reduces thawing time compared to traditional methods like blast chilling or refrigeration.

Overview of Blast Chilling Technology

Blast chilling technology rapidly cools food by circulating extremely cold air, reducing the temperature from cooking to refrigeration levels within a short time frame. This method preserves food quality, texture, and nutritional value by minimizing bacterial growth and preventing partial cooking that often occurs with microwave defrosting. Compared to microwaving, blast chilling offers a safer and more consistent food thawing process, ideal for maintaining freshness in commercial kitchens and food service operations.

Speed Comparison: Microwave vs Blast Chiller

Microwave defrosting significantly reduces thawing time, typically taking just a few minutes compared to several hours required by blast chillers. This rapid method uses electromagnetic waves to excite water molecules, quickly warming frozen food from the inside out.

Blast chilling defrosts food by gradually lowering the temperature, preserving texture and reducing bacterial growth, which is crucial for food safety. Although slower, usually 1-3 hours depending on food type and size, blast chilling ensures even thawing without partial cooking. Microwave defrosting offers speed but risks uneven thawing and possible nutrient loss, making blast chilling preferred for quality-focused food preparation.

Effects on Food Texture and Quality

Defrosting in a microwave rapidly heats food, often causing uneven thawing that can lead to partial cooking and a compromised texture, especially for delicate items like meat and fish. This method may result in moisture loss and a rubbery or dry surface, reducing overall food quality.

Blast chilling gradually lowers the temperature of frozen food with controlled airflow, preserving the cell structure and moisture content more effectively than microwaving. This gentle thawing process minimizes texture degradation, maintaining the food's original taste and mouthfeel for superior quality.

Safety Considerations in Both Methods

Microwaving defrosts food quickly by applying heat, which may create uneven temperatures and promote bacterial growth in partially warmed areas. Blast chilling gently thaws food through cold air circulation, maintaining safe temperatures to minimize microbial risks.

- Microwave defrost risk - Uneven heating during microwaving can result in bacterial hotspots due to partial cooking.

- Blast chilling safety - Blast chilling preserves food integrity by keeping temperatures consistently low, reducing pathogen proliferation.

- Time sensitivity - Both methods require subsequent prompt cooking or refrigeration to maintain food safety standards.

Nutritional Impact of Each Thawing Technique

Defrosting in a microwave can lead to uneven heating, potentially causing nutrient loss due to localized overheating, especially of heat-sensitive vitamins like vitamin C and B-complex. This method may also partially cook food during thawing, altering its texture and reducing its overall nutritional quality.

Blast chilling preserves nutritional integrity by thawing food rapidly at low temperatures, minimizing enzymatic and microbial activity that can degrade nutrients. This technique maintains the food's moisture content and texture better, resulting in higher retention of essential vitamins and antioxidants compared to microwave defrosting.

Energy Efficiency: Microwave vs Blast Chilling

Microwaving for defrosting uses less energy due to its rapid heating process, while blast chilling maintains lower energy consumption by operating efficiently at cold temperatures. Energy efficiency in blast chilling is often higher in commercial settings where large volumes require thawing without temperature fluctuation.

- Microwave Defrosting Efficiency - Utilizes direct electromagnetic waves to rapidly heat food, reducing overall energy usage.

- Blast Chilling Energy Consumption - Employs low temperatures and strong airflow, consuming steady but often lower energy over time.

- Volume Impact - Blast chilling is more energy-efficient for large-scale thawing compared to microwaving small individual portions.

Choosing between microwaving and blast chilling for defrosting depends on food volume and energy cost priorities.

Practicality for Home and Commercial Use

| Microwave defrosting offers rapid thawing times, making it highly practical for home use where convenience and speed are prioritized. Blast chilling, while slower, ensures uniform thawing and reduces bacterial growth, which is essential for commercial kitchens adhering to strict food safety standards. Home users benefit from the microwave's accessibility and time-saving features, whereas commercial settings value blast chilling for its capacity to maintain food quality and safety during large-scale thawing. |

Related Important Terms

Rapid-cycling microwave thawing

Rapid-cycling microwave thawing utilizes intermittent bursts of microwave energy to quickly and evenly defrost food, minimizing partial cooking and moisture loss compared to conventional microwaving. Blast chilling, while effective for preserving food quality by rapidly lowering temperatures, is less efficient for thawing due to its slower heat transfer and longer processing times.

IQF microwave defrost

Defrosting IQF (Individually Quick Frozen) foods in a microwave offers rapid thawing by targeting ice crystals without significantly raising the temperature of surrounding areas, preserving texture and moisture. Blast chilling, while slower, maintains even temperature distribution and reduces microbial growth risks, yet its longer duration can affect production timelines compared to microwave defrosting efficiency.

Pulsed energy microwave de-icing

Pulsed energy microwave de-icing offers rapid and uniform thawing by emitting controlled microwave pulses that minimize thermal gradients and preserve food quality compared to conventional blast chilling methods. This technique reduces thawing time significantly while maintaining texture and reducing microbial growth risk, outperforming traditional cold-based defrosting processes.

Cryogenic blast chilling

Cryogenic blast chilling rapidly reduces food temperature using liquid nitrogen or carbon dioxide, preserving texture and nutritional quality better than microwave defrosting, which can cause uneven thawing and partial cooking. This method is ideal for maintaining food safety and preventing bacterial growth during thawing in commercial food processing.

Thermal runaway in microwave thaw

Microwave thawing can induce thermal runaway, where uneven heating causes some food areas to overheat while others remain frozen, increasing the risk of bacterial growth and foodborne illness. In contrast, blast chilling offers controlled, uniform thawing by rapidly lowering the temperature to safe levels without triggering thermal hotspots, preserving food quality and safety.

Dielectric thawing

Dielectric thawing in microwaves rapidly heats polar water molecules within food, enabling faster defrosting compared to traditional blast chilling, which relies on cold air to slowly lower temperature. While microwave defrosting prevents microbial growth due to shorter thaw times, blast chilling better preserves texture and moisture by avoiding uneven heating and partial cooking often caused by dielectric heating.

Surface dehydration effect (microwave)

Microwaving for defrosting often causes surface dehydration due to uneven heat exposure, leading to dry, tough outer layers while the interior remains frozen. In contrast, blast chilling thaws food uniformly by rapidly lowering temperature without moisture loss, preserving texture and juiciness.

Refreezing risk in blast chilling

Microwaving defrosts food quickly by using electromagnetic waves, reducing bacterial growth risk compared to blast chilling, which cools food rapidly but leaves it partially frozen, increasing the risk of bacterial proliferation if refrozen improperly. Blast chilling requires careful handling to avoid refreezing thawed food, as fluctuating temperatures can promote harmful microbial activity and food safety issues.

Cold chain microwave integration

Cold chain microwave integration enhances defrosting by combining precise, rapid thawing with continuous temperature control, minimizing microbial growth compared to traditional blast chilling. This method preserves food quality and safety by maintaining consistent cold chain protocols throughout the microwave defrosting process.

Defrosting in microwave vs Blast chilling for food thawing. Infographic

cookingdiff.com

cookingdiff.com