Borosilicate containers are ideal for microwaving pets because they offer superior heat resistance and durability compared to regular glass containers. These containers withstand rapid temperature changes without cracking, ensuring safe and even heating. Glass containers, on the other hand, may not tolerate extreme microwave temperatures as well, increasing the risk of breakage and uneven heating.

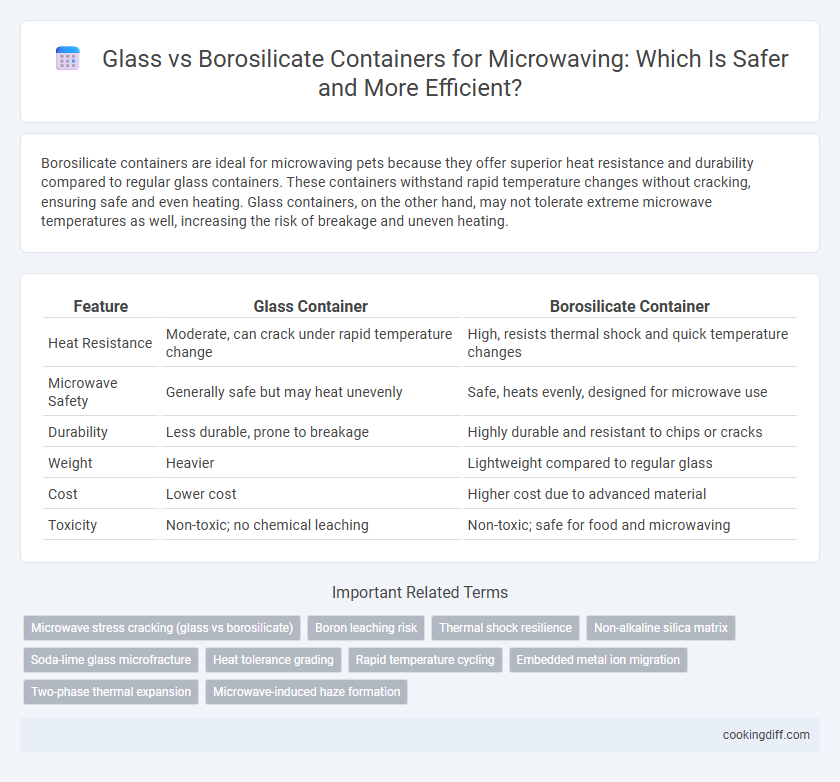

Table of Comparison

| Feature | Glass Container | Borosilicate Container |

|---|---|---|

| Heat Resistance | Moderate, can crack under rapid temperature change | High, resists thermal shock and quick temperature changes |

| Microwave Safety | Generally safe but may heat unevenly | Safe, heats evenly, designed for microwave use |

| Durability | Less durable, prone to breakage | Highly durable and resistant to chips or cracks |

| Weight | Heavier | Lightweight compared to regular glass |

| Cost | Lower cost | Higher cost due to advanced material |

| Toxicity | Non-toxic; no chemical leaching | Non-toxic; safe for food and microwaving |

Introduction: Glass vs Borosilicate Containers for Microwaving

Glass containers are widely used for microwaving due to their non-reactive nature and affordable price. Borosilicate containers, made from a special type of glass, offer superior thermal resistance compared to ordinary glass.

Borosilicate glass can withstand rapid temperature changes without cracking, making it ideal for microwave use. Regular glass containers may shatter if exposed to sudden heat spikes, posing safety risks. Choosing borosilicate containers enhances durability and microwave safety during cooking.

What is Regular Glass?

Regular glass containers are typically made from soda-lime glass, which is less resistant to thermal shock compared to borosilicate glass. When microwaving, these containers may crack or shatter due to rapid temperature changes, making them less ideal for high-heat applications.

- Composition - Regular glass is primarily soda-lime glass, composed of silica, soda, and lime.

- Thermal Resistance - It has lower thermal shock resistance, increasing the risk of breakage in microwave use.

- Usage - Suitable for moderate heating but not recommended for frequent or intense microwaving.

What is Borosilicate Glass?

Borosilicate glass is a type of glass known for its high resistance to thermal shock, making it ideal for microwaving and cooking. It contains silica and boron trioxide, which provide durability and prevent cracking under rapid temperature changes.

Compared to regular glass containers, borosilicate glass offers superior heat tolerance and chemical resistance, ensuring safer use in microwaves. This makes it a popular choice for cookware and storage that require both strength and heat safety.

Microwave Safety: Glass vs Borosilicate

Standard glass containers are generally microwave-safe but can crack due to thermal shock from sudden temperature changes. Borosilicate containers resist thermal shock better, making them safer for repeated microwave use.

- Thermal Resistance - Borosilicate glass withstands rapid temperature changes without cracking, unlike some standard glass containers.

- Durability - Borosilicate is more durable and less prone to breakage in microwaves, extending its lifespan.

- Chemical Stability - Both are chemically inert, but borosilicate maintains integrity longer during intense microwave heating.

Using borosilicate containers enhances microwave safety by reducing the risk of breakage and ensuring consistent performance.

Heat Resistance Comparison

Borosilicate glass containers exhibit superior heat resistance compared to standard glass containers, with the ability to withstand rapid temperature changes up to 450degF (232degC) without cracking. Regular glass containers typically tolerate lower temperatures and are more susceptible to thermal shock during microwaving. Choosing borosilicate glass ensures safer use and longer durability in microwave applications due to its enhanced thermal stability.

Durability and Breakage

Glass containers are prone to thermal shock and can break or crack when exposed to rapid temperature changes in microwaving. Borosilicate glass containers offer superior durability because their composition resists thermal stress more effectively, reducing the risk of breakage.

Borosilicate glass is engineered to withstand high temperatures and sudden heating, making it a safer and longer-lasting option for microwave use. Standard glass containers, while often microwave-safe, generally have a higher likelihood of damage over time due to repeated heating cycles.

Food Flavor and Stain Resistance

Glass containers generally maintain food flavor well but can absorb stains and odors over time, affecting taste. Borosilicate containers resist stains and odors better, preserving food flavor more effectively during microwaving.

- Flavor retention in glass - Standard glass can sometimes retain slight odors, subtly impacting the flavor of microwaved food.

- Stain resistance in borosilicate - Borosilicate glass offers superior resistance to staining from strong spices and sauces, ensuring cleaner containers.

- Microwave safety and taste preservation - Borosilicate's chemical durability minimizes flavor contamination, making it ideal for repeated microwave use.

Ease of Cleaning

Which container is easier to clean after microwaving, glass or borosilicate? Glass containers often have a smooth surface that resists staining and odor retention, making them easier to clean with minimal scrubbing. Borosilicate containers offer similar benefits but excel in durability, maintaining their non-porous surface despite frequent use and thermal stress.

Cost and Accessibility

| Glass Containers | Generally more affordable and widely available in most retail stores and supermarkets. |

| Borosilicate Containers | Typically costlier due to enhanced thermal resistance but are accessible through specialty kitchenware and online retailers. |

Related Important Terms

Microwave stress cracking (glass vs borosilicate)

Borosilicate glass containers exhibit superior resistance to microwave stress cracking compared to regular glass, due to their enhanced thermal shock durability and low thermal expansion coefficient. This makes borosilicate containers more reliable for repeated microwave use, minimizing the risk of fractures or cracks caused by rapid temperature changes.

Boron leaching risk

Borosilicate containers offer superior thermal resistance for microwaving but pose a minimal risk of boron leaching, especially when exposed to acidic foods or prolonged high heat. Glass containers generally have a lower risk of chemical leaching, making them a safer choice for everyday microwaving, particularly with diverse food types.

Thermal shock resilience

Borosilicate containers exhibit superior thermal shock resilience compared to standard glass containers, making them ideal for microwaving as they withstand rapid temperature changes without cracking. Their composition reduces the risk of breakage under high heat, ensuring safer and more durable performance in microwave ovens.

Non-alkaline silica matrix

Glass containers with a non-alkaline silica matrix offer excellent microwave safety due to their thermal stability and resistance to chemical interactions, minimizing the risk of leaching harmful substances. Borosilicate containers, known for their non-alkaline silica composition, provide superior heat resistance and durability under rapid temperature changes, making them ideal for microwave use without cracking or warping.

Soda-lime glass microfracture

Soda-lime glass containers are prone to developing microfractures during microwaving due to rapid thermal expansion, compromising their durability and safety. Borosilicate containers withstand microwave heat more effectively, resisting thermal shock and preventing microfractures for enhanced longevity.

Heat tolerance grading

Borosilicate glass containers offer superior heat tolerance, withstanding temperatures up to 450degC, making them ideal for microwave use due to their resistance to thermal shock. Standard glass containers typically tolerate lower temperatures around 150-200degC and may crack or shatter under rapid temperature changes during microwaving.

Rapid temperature cycling

Borosilicate containers excel under rapid temperature cycling in microwaving due to their low thermal expansion, minimizing the risk of cracking compared to standard glass containers. Their superior thermal shock resistance ensures durability when transitioning quickly between high and low temperatures during microwave use.

Embedded metal ion migration

Glass containers typically pose minimal risk of embedded metal ion migration when microwaved, ensuring food safety and preserving flavor integrity. Borosilicate containers, known for thermal resistance, also exhibit low metal ion leaching but may contain trace amounts of metal oxides designed to enhance durability without compromising microwaving safety.

Two-phase thermal expansion

Glass containers often experience uneven heating in microwaves due to their higher coefficient of thermal expansion, which can cause stress and cracking during rapid temperature changes. Borosilicate containers feature two-phase thermal expansion with a lower expansion rate, allowing them to withstand sudden temperature fluctuations more effectively and resist thermal shock in microwaving applications.

Glass container vs borosilicate container for microwaving. Infographic

cookingdiff.com

cookingdiff.com