Microwave defrosting uses electromagnetic waves to quickly heat frozen foods, reducing thawing time but often causing uneven heating and partial cooking. Ultrasonic thawing employs high-frequency sound waves to generate heat uniformly within the food, preserving texture and nutrient content while minimizing drip loss. Comparing the two, ultrasonic thawing offers a gentler, more consistent method ideal for delicate frozen foods, whereas microwave defrosting is faster but may compromise quality due to uneven heat distribution.

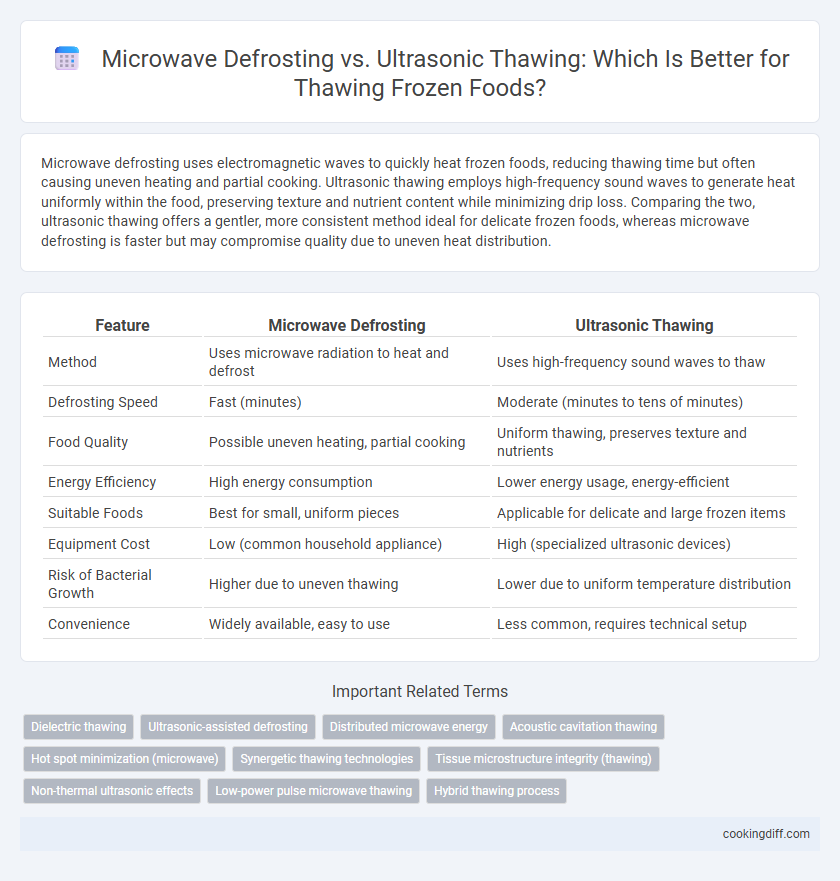

Table of Comparison

| Feature | Microwave Defrosting | Ultrasonic Thawing |

|---|---|---|

| Method | Uses microwave radiation to heat and defrost | Uses high-frequency sound waves to thaw |

| Defrosting Speed | Fast (minutes) | Moderate (minutes to tens of minutes) |

| Food Quality | Possible uneven heating, partial cooking | Uniform thawing, preserves texture and nutrients |

| Energy Efficiency | High energy consumption | Lower energy usage, energy-efficient |

| Suitable Foods | Best for small, uniform pieces | Applicable for delicate and large frozen items |

| Equipment Cost | Low (common household appliance) | High (specialized ultrasonic devices) |

| Risk of Bacterial Growth | Higher due to uneven thawing | Lower due to uniform temperature distribution |

| Convenience | Widely available, easy to use | Less common, requires technical setup |

Introduction to Frozen Food Thawing Methods

Microwave defrosting uses electromagnetic waves to rapidly heat frozen food, reducing thawing time while maintaining safety. Ultrasonic thawing employs high-frequency sound waves to generate localized heat within the food, promoting even thawing without cooking the edges. Both methods offer distinct advantages in preserving food quality and texture during the defrosting process.

Understanding Microwave Defrosting Technology

How does microwave defrosting technology work compared to ultrasonic thawing for frozen foods? Microwave defrosting uses electromagnetic waves to agitate water molecules in food, generating heat and accelerating the thawing process. This method offers faster defrosting times but may cause uneven heating, unlike ultrasonic thawing which uses high-frequency sound waves to gently and uniformly defrost frozen items without heat buildup.

What Is Ultrasonic Thawing?

Ultrasonic thawing uses high-frequency sound waves to generate localized heat within frozen foods, accelerating the defrosting process without compromising texture or flavor. This method reduces thawing time compared to traditional microwave defrosting, which often causes uneven heating and partial cooking. Ultrasonic thawing is especially effective for delicate items like seafood and fruits, preserving quality while ensuring food safety.

Speed Comparison: Microwave vs Ultrasonic Thawing

Microwave defrosting significantly reduces thawing time by using electromagnetic waves to heat water molecules rapidly. Ultrasonic thawing employs high-frequency sound waves to generate heat within the food, offering a more uniform but slower thawing process.

- Microwave defrosting speed - Typically completes thawing in minutes, making it ideal for quick meal preparation.

- Ultrasonic thawing speed - Takes longer than microwave defrosting but provides gentler, more even thawing to preserve texture.

- Heat distribution - Microwave defrosting can cause uneven heating and partial cooking, while ultrasonic thawing promotes consistent temperature throughout.

Impact on Food Quality and Texture

Microwave defrosting rapidly heats frozen foods, often causing uneven thawing and partial cooking, which can negatively affect food texture and lead to moisture loss. This method may result in tougher, drier textures, especially in delicate items like seafood and poultry.

Ultrasonic thawing uses high-frequency sound waves to gently and evenly defrost frozen foods, preserving cell structure and moisture content. The technique maintains better food quality, enhancing texture and reducing nutrient degradation compared to microwave defrosting.

Nutrient Retention: Which Method Preserves More?

Microwave defrosting often results in uneven heating, which can cause nutrient loss due to localized overheating, whereas ultrasonic thawing uses high-frequency sound waves that gently and uniformly thaw frozen foods, better preserving their nutritional profile. Studies show ultrasonic thawing retains higher levels of vitamins and antioxidants compared to microwave defrosting, making it a superior choice for nutrient retention.

- Microwave defrosting nutrient degradation - Rapid heating can break down heat-sensitive nutrients like vitamin C and B vitamins.

- Ultrasonic thawing efficiency - Uniform thawing minimizes nutrient loss by avoiding hot spots and overheating.

- Scientific evidence - Research indicates ultrasonic thawed foods retain up to 20% more antioxidants than microwave-defrosted counterparts.

Choosing ultrasonic thawing enhances the preservation of essential nutrients in frozen foods compared to traditional microwave defrosting.

Safety Considerations in Thawing Frozen Foods

Microwave defrosting rapidly raises food temperature, which can create uneven thawing and potentially allow harmful bacteria to grow in warmer areas. Ultrasonic thawing uses high-frequency sound waves to gently and uniformly thaw frozen foods, reducing microbial risks associated with partial warming.

Ensuring food safety during thawing requires maintaining temperatures that inhibit bacterial growth, with ultrasonic thawing offering more controlled temperature regulation. Microwave thawing often demands immediate cooking to prevent pathogen development in hotspots. Choosing the appropriate thawing method is critical to preserving food quality and preventing foodborne illnesses.

Energy Efficiency: Microwave vs Ultrasonic Methods

Microwave defrosting typically consumes more energy due to rapid heating cycles, whereas ultrasonic thawing uses less power by employing mechanical vibrations to gently warm frozen food. Ultrasonic thawing offers enhanced energy efficiency by minimizing heat loss and avoiding hot spots common in microwaves.

- Microwave defrosting energy use - Rapid electromagnetic wave heating requires higher wattage, leading to increased energy consumption during short thawing periods.

- Ultrasonic thawing efficiency - Mechanical vibrations use lower energy input to directly agitate frozen molecules, resulting in steady and uniform thawing.

- Heat distribution - Ultrasonic method reduces thermal gradients, preventing overheating and energy waste typical in microwave defrosting.

Practical Applications in Home and Industrial Settings

| Microwave defrosting is favored in home kitchens for its speed and convenience, quickly thawing a variety of frozen foods by agitating water molecules with electromagnetic waves. Ultrasonic thawing, utilized primarily in industrial settings, employs high-frequency sound waves to uniformly and gently thaw large quantities of frozen products, preserving texture and reducing nutrient loss. Both methods optimize the defrosting process but differ in scalability and impact on food quality, with microwaving suited for small portions and ultrasonic thawing ideal for commercial food processing. |

Related Important Terms

Dielectric thawing

Microwave defrosting utilizes dielectric heating, rapidly agitating water molecules in frozen foods to generate internal heat, which can cause uneven thawing and partial cooking at the edges. Ultrasonic thawing employs high-frequency sound waves to induce mechanical vibrations and localized heating, providing more uniform defrosting with minimal thermal damage and better preservation of food quality.

Ultrasonic-assisted defrosting

Ultrasonic-assisted defrosting accelerates the thawing of frozen foods by generating high-frequency sound waves that induce mechanical vibrations, promoting uniform heat distribution and reducing nutrient loss compared to conventional microwave defrosting. This method minimizes surface overheating and preserves texture by preventing partial cooking commonly seen in microwave defrosting processes, making it a superior technology for maintaining food quality during thawing.

Distributed microwave energy

Microwave defrosting utilizes distributed microwave energy that penetrates frozen foods, causing water molecules to vibrate and generate heat rapidly, yet often results in uneven thawing due to energy distribution inconsistencies. Ultrasonic thawing, by contrast, employs high-frequency sound waves to induce localized vibrations and mechanical energy, providing more uniform thawing without the hot spots typically associated with microwave energy dispersion.

Acoustic cavitation thawing

Acoustic cavitation thawing uses ultrasonic waves to generate microscopic bubbles that collapse and release energy, evenly heating frozen foods without partially cooking or drying them, unlike microwave defrosting which often causes uneven thawing and texture degradation. This method enhances food safety by minimizing microbial growth due to uniform temperature distribution and preserves quality better by reducing moisture loss and protein denaturation.

Hot spot minimization (microwave)

Microwave defrosting often creates uneven heating and hot spots that can partially cook food, compromising texture and safety, whereas ultrasonic thawing distributes energy more uniformly, significantly reducing hot spot formation. This consistent energy application of ultrasonic thawing preserves food quality by ensuring even temperature elevation throughout frozen items.

Synergetic thawing technologies

Microwave defrosting rapidly heats frozen foods by agitating water molecules, while ultrasonic thawing employs high-frequency sound waves to generate uniform heat and minimize texture damage. Combining these synergetic thawing technologies enhances defrosting efficiency, reduces nutrient loss, and preserves food quality by balancing speed and gentle heat distribution.

Tissue microstructure integrity (thawing)

Microwave defrosting often causes uneven heating that can damage tissue microstructure integrity, leading to cell rupture and loss of texture in frozen foods. Ultrasonic thawing preserves tissue microstructure by promoting uniform ice crystal melting with minimal thermal damage, maintaining food quality and texture more effectively.

Non-thermal ultrasonic effects

Non-thermal ultrasonic effects during ultrasonic thawing enhance ice crystal disruption and accelerate cell membrane permeability without heat generation, preserving food quality better than microwave defrosting, which relies on rapid heating that can cause uneven thawing and partial cooking. Ultrasonic thawing improves texture retention and reduces nutrient loss by minimizing thermal damage, making it a superior method for delicate frozen foods compared to microwave defrosting.

Low-power pulse microwave thawing

Low-power pulse microwave thawing offers precise temperature control and reduces the risk of uneven heating compared to conventional microwave defrosting, preserving food quality and texture. Ultrasonic thawing, while effective in accelerating thawing times, may cause localized heating and protein denaturation, making low-power pulse microwaving a preferred method for delicate frozen foods.

Microwave defrosting vs Ultrasonic thawing for frozen foods. Infographic

cookingdiff.com

cookingdiff.com