Microwaving heats food quickly but is not effective for rapidly cooling leftovers, which can lead to uneven temperature distribution and potential bacterial growth. Rapid chillers are designed to cool food rapidly and uniformly, preserving texture and nutritional quality while minimizing the risk of foodborne illness. Using a rapid chiller ensures safe cooling by swiftly reducing food temperature below the danger zone, unlike microwaving, which is suited for reheating rather than cooling.

Table of Comparison

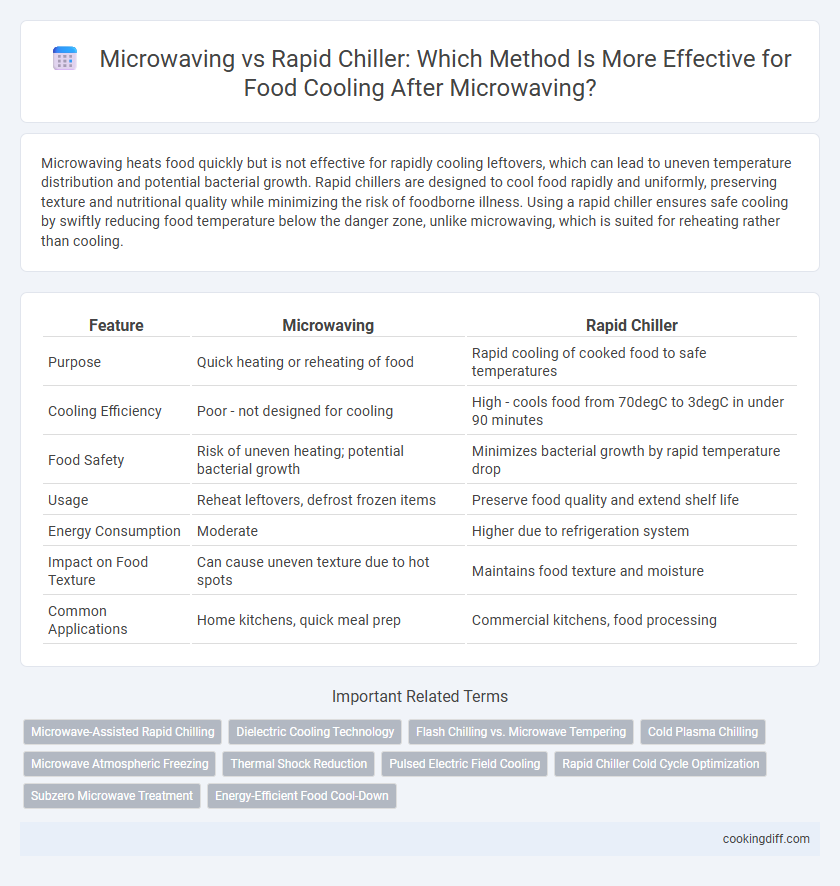

| Feature | Microwaving | Rapid Chiller |

|---|---|---|

| Purpose | Quick heating or reheating of food | Rapid cooling of cooked food to safe temperatures |

| Cooling Efficiency | Poor - not designed for cooling | High - cools food from 70degC to 3degC in under 90 minutes |

| Food Safety | Risk of uneven heating; potential bacterial growth | Minimizes bacterial growth by rapid temperature drop |

| Usage | Reheat leftovers, defrost frozen items | Preserve food quality and extend shelf life |

| Energy Consumption | Moderate | Higher due to refrigeration system |

| Impact on Food Texture | Can cause uneven texture due to hot spots | Maintains food texture and moisture |

| Common Applications | Home kitchens, quick meal prep | Commercial kitchens, food processing |

Introduction to Food Cooling Methods

What are the differences between microwaving and rapid chiller methods for food cooling? Microwaving uses electromagnetic waves to heat food quickly but does not efficiently cool it, making it unsuitable for food cooling purposes. Rapid chillers, on the other hand, lower food temperature swiftly to prevent bacterial growth, ensuring food safety and quality during the cooling process.

How Microwaving Works for Food Cooling

Microwaving uses electromagnetic waves at a frequency of 2.45 GHz to agitate water molecules within food, generating heat quickly and uniformly. Unlike rapid chillers that cool food by circulating cold air or liquid to lower temperature rapidly, microwaving primarily heats rather than cools food. This method efficiently heats food but is not suitable for rapid cooling processes required to prevent bacterial growth in perishable items.

The Rapid Chiller: Mechanism and Benefits

| Rapid Chiller Mechanism | The rapid chiller uses high-velocity cold air to lower food temperatures quickly, preserving texture and nutritional value. This accelerated cooling process reduces the risk of bacterial growth by rapidly passing through the temperature danger zone (5degC to 60degC). |

| Benefits Over Microwaving | Unlike microwaving, which heats unevenly and can alter food structure, rapid chilling maintains food safety and quality with uniform cooling. It extends shelf life by minimizing oxidation and enzymatic activity, making it essential for commercial food preservation. |

Speed Comparison: Microwaving vs Rapid Chiller

Microwaving rapidly heats food by agitating water molecules, significantly reducing cooking time compared to traditional methods. However, rapid chillers cool food faster than microwaves can heat it, lowering temperatures swiftly to prevent bacterial growth.

Microwaving typically takes minutes to heat food thoroughly, while rapid chillers can cool large food quantities from 70degC to 3degC in under 90 minutes. This speed advantage of rapid chillers is crucial in commercial kitchens for maintaining food safety. Combining microwaving for heating and rapid chilling for cooling ensures efficient and safe food processing.

Energy Efficiency: Which Method Wins?

Microwaving uses targeted energy to heat food quickly, often resulting in lower overall energy consumption compared to traditional heating methods. Rapid chillers, designed for quick cooling, consume significant energy due to refrigeration systems but can prevent bacterial growth more effectively.

- Microwaving is energy-efficient for heating - It uses electromagnetic waves to heat food directly, minimizing wasted heat.

- Rapid chillers consume more power - Their refrigeration components require continuous energy to rapidly reduce food temperature.

- Energy use depends on cooling vs heating needs - Microwaving excels at efficient heating, while rapid chillers are essential for safe and fast cooling despite higher energy consumption.

Impact on Food Safety and Shelf Life

Microwaving rapidly elevates food temperature, effectively reducing microbial load and enhancing immediate food safety by minimizing the time food spends in the danger zone of 40degF to 140degF. However, this method may not uniformly cool food, potentially allowing some areas to remain warm and promote bacterial growth if not properly managed.

Rapid chillers uniformly lower food temperature to safe storage levels, significantly extending shelf life by slowing microbial activity and enzymatic reactions. Consistent rapid cooling prevents spoilage and maintains food quality, making it a superior option for long-term food safety and preservation in commercial settings.

Nutrient Retention: Microwaving vs Rapid Chilling

Microwaving preserves more water-soluble vitamins like vitamin C and B-complex due to shorter cooking times and reduced exposure to heat. Rapid chilling maintains nutrient levels by quickly lowering the temperature to inhibit enzymatic activity and microbial growth.

- Microwaving reduces nutrient loss - By using electromagnetic waves, microwaving cooks food faster and retains more heat-sensitive nutrients compared to traditional methods.

- Rapid chilling slows nutrient degradation - Immediate cooling after cooking helps preserve essential nutrients by preventing prolonged exposure to heat.

- Effectiveness depends on food type - Nutrient retention varies with the nature of the food and the specific nutrients involved in each cooling method.

Choosing microwaving or rapid chilling effectively enhances nutrient retention depending on the food preparation and storage requirements.

Best Use Cases for Each Cooling Technique

Microwaving is ideal for quickly reheating individual portions and small quantities of food, ensuring rapid temperature increase without altering texture. Rapid chillers excel in safely cooling large batches of cooked food, preserving quality and preventing bacterial growth.

- Microwaving for reheating. Best suited for fast, convenient warming of single servings or leftovers.

- Rapid chilling for batch cooling. Effective in rapidly lowering temperature of bulk foods to comply with food safety regulations.

- Texture preservation. Rapid chillers maintain food texture better during cooling compared to microwaving.

Cost Analysis: Equipment and Operation

Microwaving equipment typically requires lower initial investment compared to rapid chillers, making it more accessible for small to medium food operations. Operational costs for microwaving are generally higher due to increased energy consumption and maintenance demands over time.

Rapid chillers involve a higher upfront equipment cost but offer significant savings in operational expenses by reducing energy use through efficient cooling cycles. The overall cost efficiency of rapid chillers improves in large-scale or high-volume environments where fast, consistent cooling is critical.

Related Important Terms

Microwave-Assisted Rapid Chilling

Microwave-Assisted Rapid Chilling combines microwave energy with rapid chilling technology to accelerate the cooling process, significantly reducing microbial growth and preserving food quality compared to traditional rapid chillers alone. This method enhances heat removal efficiency by uniformly distributing microwaves, leading to faster temperature reduction and improved food safety in commercial kitchens.

Dielectric Cooling Technology

Microwaving employs Dielectric Cooling Technology to reduce cooling times by uniformly distributing electromagnetic energy within food, leading to faster and more consistent temperature drops compared to traditional Rapid Chillers. This advanced method minimizes microbial growth risks by accelerating the cooling process, preserving food quality and safety more effectively than conventional chilling techniques.

Flash Chilling vs. Microwave Tempering

Flash chilling rapidly lowers food temperature to inhibit bacterial growth, preserving texture and safety, while microwave tempering uses controlled energy to quickly soften frozen food for faster preparation without partial cooking. Flash chilling enhances shelf life and quality post-cooking, whereas microwave tempering focuses on expediting thawing to reduce overall meal prep time.

Cold Plasma Chilling

Cold plasma chilling offers a rapid and energy-efficient alternative to traditional microwaving methods by using ionized gas to reduce food temperature while maintaining quality and safety. Compared to rapid chillers, cold plasma chilling minimizes microbial contamination and preserves nutritional content without thermal damage, making it an advanced technique for effective food cooling.

Microwave Atmospheric Freezing

Microwave Atmospheric Freezing combines the rapid heat removal capabilities of microwaving with atmospheric freezing conditions, enabling faster core temperature reduction in foods compared to traditional rapid chillers. This method enhances food safety and texture preservation by minimizing ice crystal formation during freezing, making it a superior option for industrial food cooling processes.

Thermal Shock Reduction

Microwaving rapidly elevates food temperature unevenly, increasing the risk of thermal shock and compromising texture, whereas rapid chillers uniformly reduce food temperature, effectively minimizing thermal shock by stabilizing cellular structure. Utilizing rapid chillers enhances food safety and quality by ensuring controlled cooling rates that prevent damage caused by abrupt temperature changes.

Pulsed Electric Field Cooling

Pulsed Electric Field (PEF) cooling offers a rapid and energy-efficient alternative to conventional microwaving and rapid chilling by disrupting cell membranes to accelerate heat transfer and preserve food quality. Compared to traditional rapid chillers, PEF cooling reduces cooling time significantly while maintaining texture, flavor, and nutritional content, making it an innovative approach for post-processing in the food industry.

Rapid Chiller Cold Cycle Optimization

Rapid chiller cold cycle optimization significantly enhances food safety by reducing cooling time from 2 hours to under 90 minutes, minimizing bacterial growth compared to microwaving which provides uneven heating. This method ensures consistent, rapid temperature drops from 60degC to below 5degC, preserving food quality and extending shelf life efficiently.

Subzero Microwave Treatment

Subzero Microwave Treatment rapidly lowers the internal temperature of food by combining microwave energy with subzero cooling, significantly reducing bacterial growth compared to Rapid Chiller methods. This innovative technology shortens cooling times while preserving food quality and safety, making it superior for industrial food processing.

Microwaving vs Rapid Chiller for food cooling Infographic

cookingdiff.com

cookingdiff.com