Borosilicate glass containers offer superior thermal shock resistance compared to Pyrex dishes, making them safer for microwave baking where rapid temperature changes are common. Pyrex, often made from tempered soda-lime glass, may be more prone to breaking under sudden heat variations in microwaves. Using borosilicate glass ensures even heating and durability, reducing the risk of cracks or shattering during pet food preparation.

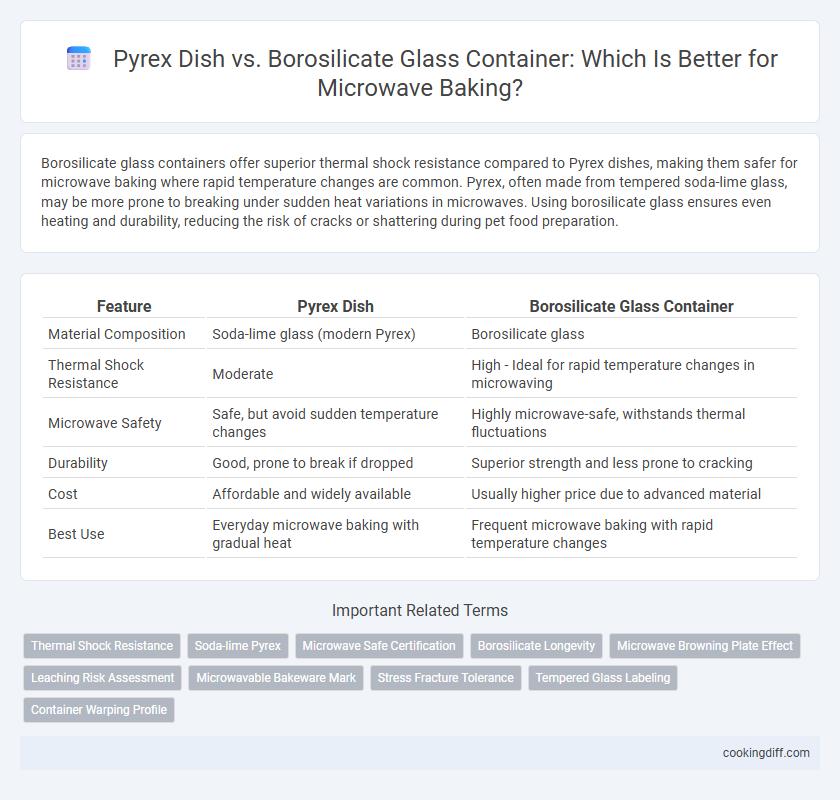

Table of Comparison

| Feature | Pyrex Dish | Borosilicate Glass Container |

|---|---|---|

| Material Composition | Soda-lime glass (modern Pyrex) | Borosilicate glass |

| Thermal Shock Resistance | Moderate | High - Ideal for rapid temperature changes in microwaving |

| Microwave Safety | Safe, but avoid sudden temperature changes | Highly microwave-safe, withstands thermal fluctuations |

| Durability | Good, prone to break if dropped | Superior strength and less prone to cracking |

| Cost | Affordable and widely available | Usually higher price due to advanced material |

| Best Use | Everyday microwave baking with gradual heat | Frequent microwave baking with rapid temperature changes |

Pyrex vs Borosilicate Glass: Understanding the Basics

Pyrex dishes are typically made from tempered soda-lime glass, which is engineered to withstand rapid temperature changes, making them suitable for microwave baking. Borosilicate glass containers feature a unique chemical composition that offers superior thermal shock resistance and durability compared to standard glass. Understanding these material differences helps in selecting the right cookware for microwave use, ensuring safety and optimal baking results.

Microwave Safety: Can Both Pyrex and Borosilicate Withstand Heat?

| Material | Heat Resistance | Microwave Safety |

| Pyrex (Soda-Lime Glass in US) | Withstands temperatures up to 425degF (218degC) | Safe for microwave use but prone to thermal shock if heated rapidly |

| Borosilicate Glass | Withstands higher temperatures up to 560degC (1040degF) | Highly microwave-safe with superior resistance to thermal shock |

Thermal Shock Resistance: Which Performs Better?

Pyrex dishes, traditionally made from borosilicate glass, offer superior thermal shock resistance compared to standard glass containers, making them ideal for microwave baking where rapid temperature changes occur. Modern Pyrex in some regions is made from tempered soda-lime glass, which has lower thermal shock resistance but improved durability against impact. Borosilicate glass containers generally perform better under extreme temperature fluctuations, reducing the risk of cracking or breaking during microwave use.

Baking Results: Texture and Evenness Compared

Pyrex dishes, made from tempered soda-lime glass, often result in uneven heat distribution during microwave baking, affecting texture consistency. Borosilicate glass containers, with higher thermal resistance, provide more uniform heat distribution, enhancing evenness and texture in baked goods.

- Heat Resistance - Borosilicate glass withstands rapid temperature changes better than Pyrex, reducing hot spots.

- Texture Consistency - Borosilicate containers promote more uniform baking, yielding consistent crumb texture.

- Durability - Pyrex is more prone to thermal shock in microwaves, potentially impacting bake quality.

Borosilicate glass containers are generally preferred for microwave baking due to superior texture and evenness results.

Transparency and Visibility During Microwave Baking

Pyrex dishes offer excellent transparency, allowing clear visibility of food as it cooks in the microwave, which helps monitor browning and bubbling. Borosilicate glass containers also provide good clarity but may have a slight tint that can reduce visibility under certain lighting conditions.

During microwave baking, Pyrex's crystal-clear glass enhances observation of food texture changes and cooking progress without opening the microwave. Borosilicate glass containers maintain durability and thermal resistance while offering sufficient visibility for most baking needs. Both materials are microwave-safe, but Pyrex is often preferred for its superior transparency that simplifies monitoring.

Durability and Lifespan in Everyday Microwave Use

Pyrex dishes, made from tempered soda-lime glass, exhibit strong thermal shock resistance but may degrade faster than borosilicate glass under frequent microwave heating cycles. Borosilicate glass containers maintain superior durability and longer lifespan due to their enhanced resistance to extreme temperature changes during everyday microwave baking.

Repeated exposure to microwaves can cause minor surface wear on Pyrex, increasing the risk of micro-cracks over time. Borosilicate glass containers typically withstand daily microwave use without significant structural damage, preserving clarity and strength for years.

Stain and Odor Resistance: Pyrex vs Borosilicate Glass

Which material offers better stain and odor resistance for microwave baking, Pyrex or borosilicate glass? Pyrex dishes, often made from tempered soda-lime glass, exhibit moderate stain and odor resistance but may retain food odors over time. Borosilicate glass containers provide superior resistance to stains and odors due to their nonporous surface and thermal durability, making them ideal for prolonged microwave use.

Ease of Cleaning After Microwave Baking

Pyrex dishes, often made from tempered soda-lime glass, may sometimes develop baked-on residues that require more vigorous scrubbing after microwave baking. Borosilicate glass containers, known for their smooth, non-porous surface, typically allow food to slide off more easily, simplifying the cleaning process.

Borosilicate glass's resistance to thermal shock means less likelihood of staining or cracking, contributing to ease of maintenance. Pyrex may occasionally show wear over time that can trap food particles, making cleaning more challenging compared to borosilicate glass containers.

Pricing and Availability: Which Offers Better Value?

Pyrex dishes generally offer a more affordable price point compared to borosilicate glass containers, making them a popular choice for everyday microwave baking. Both products are widely available, but Pyrex's brand recognition often leads to better deals and frequent promotions.

- Cost Efficiency - Pyrex dishes typically cost less, providing better initial value for budget-conscious consumers.

- Market Availability - Pyrex is more readily found in mainstream retail stores worldwide, ensuring easier access.

- Long-Term Value - Though borosilicate glass may offer superior durability, its higher price can reduce upfront affordability in the context of microwave baking containers.

Related Important Terms

Thermal Shock Resistance

Pyrex dishes, originally made from borosilicate glass known for superior thermal shock resistance, have largely been replaced in the U.S. by tempered soda-lime glass which is less resistant to rapid temperature changes. Borosilicate glass containers maintain structural integrity during microwave baking due to their low thermal expansion, reducing the risk of cracking or shattering under sudden temperature shifts.

Soda-lime Pyrex

Soda-lime Pyrex dishes, commonly used in microwave baking, are more prone to thermal stress and potential cracking compared to borosilicate glass containers, which offer superior heat resistance and durability due to their low coefficient of thermal expansion. Borosilicate glass containers maintain structural integrity and ensure even heat distribution during microwave use, making them a safer and longer-lasting choice for high-temperature baking applications.

Microwave Safe Certification

Pyrex dishes are typically made from tempered soda-lime glass with microwave-safe certification, ensuring they withstand microwave heat without shattering. Borosilicate glass containers offer superior thermal shock resistance but may lack standardized microwave-safe certification, requiring users to verify manufacturer guidelines before microwave baking.

Borosilicate Longevity

Borosilicate glass containers offer superior longevity in microwave baking due to their ability to withstand rapid temperature changes and resist thermal shock, making them less likely to crack or break over time compared to Pyrex dishes. Their enhanced durability and chemical stability ensure safer repeated use in microwave ovens, preserving both the container's integrity and the food's quality.

Microwave Browning Plate Effect

Pyrex dishes, originally made from borosilicate glass but now often manufactured with tempered soda-lime glass, differ in microwave browning performance compared to true borosilicate glass containers, as the latter offers superior thermal resistance and more even heat distribution, enhancing the microwave browning plate effect. Borosilicate glass minimizes thermal stress and reduces uneven cooking spots, making it more effective for consistent browning in microwave baking applications.

Leaching Risk Assessment

Pyrex dishes made from tempered soda-lime glass exhibit minimal leaching risks during microwave baking due to their chemical stability at high temperatures. Borosilicate glass containers provide superior resistance to thermal shock and reduce the potential for leaching, making them a safer choice for repeated microwave use in food preparation.

Microwavable Bakeware Mark

Pyrex dishes and borosilicate glass containers often differ in their microwavable bakeware marks, with borosilicate glass typically displaying a clear microwave-safe symbol due to its superior thermal resistance. Pyrex, especially in newer iterations made from soda-lime glass, may lack explicit microwave-safe markings, making it essential to verify manufacturer guidelines before microwave baking.

Stress Fracture Tolerance

Pyrex dishes made from tempered soda-lime glass generally offer lower stress fracture tolerance compared to borosilicate glass containers, which resist thermal shock more effectively in microwave baking. Borosilicate glass withstands rapid temperature changes without cracking, making it a safer choice for frequent microwave use under high heat conditions.

Tempered Glass Labeling

Pyrex dishes, often made from tempered soda-lime glass, may not always be labeled for microwave baking, whereas borosilicate glass containers typically feature clear tempered glass labeling indicating high thermal resistance suitable for microwave use. Choosing borosilicate glass with proper tempered glass certification ensures safety and durability under rapid temperature changes in microwave baking.

Pyrex dish vs borosilicate glass container for microwave baking. Infographic

cookingdiff.com

cookingdiff.com