Brine bags provide a simple and effective method for trapping gases during pet pickling by allowing excess carbon dioxide to escape through a porous material while preventing oxygen ingress. Pickle pipes offer a more controlled gas release through a one-way valve, minimizing contamination risks and maintaining an anaerobic environment. Choosing between the two depends on the desired level of precision and ease of use in managing fermentation gases.

Table of Comparison

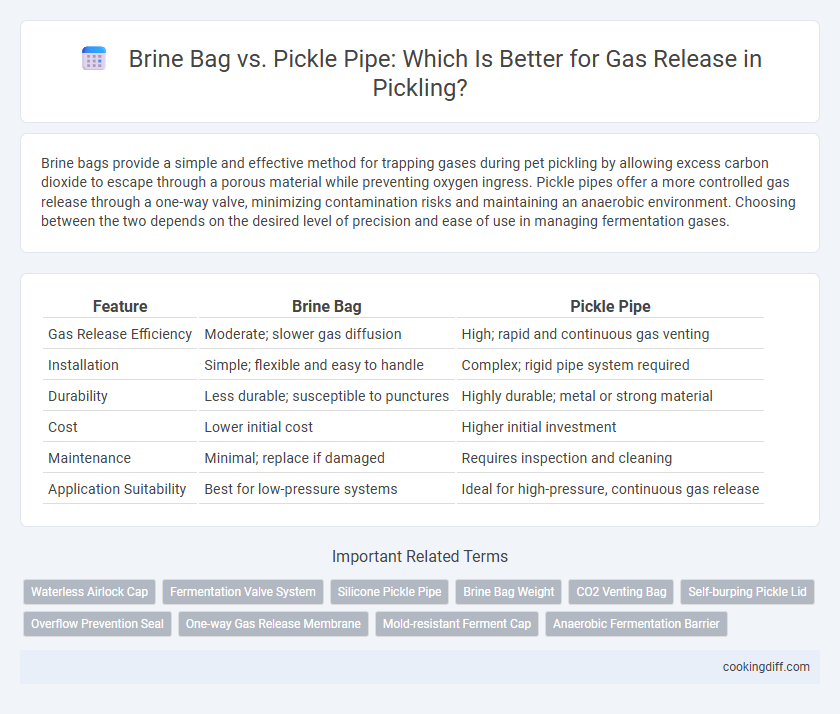

| Feature | Brine Bag | Pickle Pipe |

|---|---|---|

| Gas Release Efficiency | Moderate; slower gas diffusion | High; rapid and continuous gas venting |

| Installation | Simple; flexible and easy to handle | Complex; rigid pipe system required |

| Durability | Less durable; susceptible to punctures | Highly durable; metal or strong material |

| Cost | Lower initial cost | Higher initial investment |

| Maintenance | Minimal; replace if damaged | Requires inspection and cleaning |

| Application Suitability | Best for low-pressure systems | Ideal for high-pressure, continuous gas release |

Brine Bag vs Pickle Pipe: Key Differences in Pickling

Brine bags and pickle pipes are essential tools in industrial pickling processes for releasing trapped gases and ensuring even acid flow. Brine bags function by allowing controlled brine seepage that displaces gases, while pickle pipes provide direct venting through perforated piping systems. The choice between brine bag and pickle pipe impacts efficiency, safety, and maintenance in pickling bath management.

How Gas Release Affects Pickled Vegetables

Gas release during the pickling process is crucial for maintaining the quality and texture of pickled vegetables. Brine bags allow for gradual gas escape, reducing pressure buildup and preventing container deformation or leakage.

Pickle pipes provide a more controlled venting system that effectively releases carbon dioxide produced during fermentation. This controlled gas release helps preserve the crispness and flavor of vegetables by avoiding over-oxidation and spoilage.

Understanding the Brine Bag Method

| The brine bag method for gas release in pickling utilizes a sealed, permeable bag filled with saline solution to control effervescence and prevent gas buildup during metal surface treatment. This technique allows for the gradual escape of hydrogen gas, reducing pressure risks and enhancing safety compared to the traditional pickle pipe, which directly channels gas but may cause rapid release and splashing of acidic solutions. Optimizing gas release with brine bags improves process efficiency, minimizing hazardous exposure while maintaining the effectiveness of the pickling chemical reaction. |

What Is a Pickle Pipe and How Does It Work?

A pickle pipe is a specialized perforated pipe used in industrial pickling to allow the controlled release of gases generated during the acid treatment of metals. It functions by channeling hydrogen and other gases away from the metal surface, reducing the risk of pressure build-up and enhancing safety. Unlike brine bags, which rely on liquid barriers to contain gases, pickle pipes provide a direct ventilation path, improving process efficiency and gas management.

Fermentation Safety: Brine Bags vs Pickle Pipes

Brine bags and pickle pipes serve crucial roles in managing gas release during fermentation, directly impacting fermentation safety by preventing pressure buildup. Choosing the right method can mitigate risks of container rupture and contamination.

- Brine Bags Provide Controlled Gas Release - They allow CO2 to escape gradually while preventing oxygen from entering, maintaining anaerobic fermentation conditions.

- Pickle Pipes Enable Direct Gas Venting - These pipes release fermentation gases efficiently but may require careful monitoring to avoid contamination risks.

- Fermentation Safety Depends on Proper Equipment Use - Both brine bags and pickle pipes reduce pressure safely when used correctly, minimizing the chances of jar failure and spoilage.

Ease of Use: Which Method Is More Beginner-Friendly?

Which method is easier for beginners when managing gas release during pickling, brine bags or pickle pipes? Brine bags are often preferred for their simplicity, requiring minimal setup and less monitoring, making them ideal for novice picklers. Pickle pipes, while effective, demand more precise handling and understanding of airflow, which may pose a challenge for beginners.

Taste and Texture: Does Gas Release Method Matter?

The choice between a brine bag and a pickle pipe significantly influences the gas release during pickling, impacting the final taste and texture of the product. Brine bags allow gentle fermentation and controlled CO2 escape, preserving crispness and enhancing flavor complexity.

Pickle pipes provide a direct gas release mechanism, which can expedite fermentation but may lead to a slightly softer texture and less nuanced taste due to faster gas escape. The controlled environment in brine bags maintains anaerobic conditions that favor probiotic development and sourness. Consequently, selecting the gas release method plays a crucial role in achieving the desired sensory qualities in pickled goods.

Cleaning and Maintenance: Brine Bags Compared to Pickle Pipes

Brine bags offer easier cleaning and maintenance due to their flexible material, which allows thorough washing and quick drying. Pickle pipes, being rigid and enclosed, often require specialized equipment for internal cleaning and can accumulate residues over time.

- Brine bags are detachable - allowing for simple removal and manual scrubbing or machine washing.

- Pickle pipes have narrow internal channels - making it difficult to access and clean all contaminated surfaces effectively.

- Brine bags' porous structure - facilitates quicker drainage and reduces buildup compared to rigid pipes.

Choosing brine bags reduces downtime during maintenance and enhances sanitation efficiency in pickling operations.

Cost Analysis: Brine Bags vs Pickle Pipes for Home Picklers

Brine bags offer a low-cost, flexible option for gas release during home pickling, typically priced under $15 per unit, making them accessible for small-batch picklers. They allow for easy venting of fermentation gases without expensive equipment, reducing initial investment.

Pickle pipes, while more costly upfront at approximately $40 to $60, provide a durable and reusable solution that enhances long-term efficiency. Their sealed design minimizes contamination risk and maintenance costs, potentially offsetting the higher initial price over repeated use.

Related Important Terms

Waterless Airlock Cap

Waterless airlock caps enhance fermentation control by enabling efficient gas release while preventing oxygen ingress, outperforming traditional brine bags and pickle pipes that rely on liquid barriers. These caps reduce contamination risks and evaporation, maintaining optimal anaerobic conditions essential for consistent pickling results.

Fermentation Valve System

The fermentation valve system effectively controls gas release during pickling by utilizing either a brine bag or a pickle pipe, each facilitating pressure regulation to prevent contamination. Brine bags offer flexible, inflation-based gas release, while pickle pipes provide a more rigid, continuous venting solution, optimizing fermentation conditions for consistent product quality.

Silicone Pickle Pipe

Silicone pickle pipes provide a flexible, durable solution for controlled gas release during the pickling process, outperforming traditional brine bags by preventing contamination and ensuring consistent fermentation. Their resistance to chemical corrosion and temperature variation makes silicone pipes ideal for maintaining optimal anaerobic conditions and improving overall pickle quality.

Brine Bag Weight

Brine bags use weighted pressure to control gas release during pickling, ensuring consistent fermentation by preventing unwanted air from entering the container. The weight of the brine bag is crucial for maintaining an optimal seal without crushing the vegetables, balancing fermentation gas release and protecting the pickles' texture.

CO2 Venting Bag

CO2 venting bags in pickling provide a controlled release of fermentation gases, minimizing pressure buildup and preventing container rupture, unlike pickle pipes that allow continuous gas escape but risk contamination. Optimizing brine bag design enhances anaerobic fermentation by ensuring effective CO2 venting and maintaining pickle quality.

Self-burping Pickle Lid

The Self-burping Pickle Lid enhances gas release in pickling by automatically venting CO2 through a built-in valve, reducing the need for manual burping associated with brine bags and pickle pipes. This innovation ensures consistent fermentation while minimizing exposure to oxygen, preventing spoilage and promoting optimal flavor development.

Overflow Prevention Seal

Brine bags provide an effective overflow prevention seal by allowing controlled gas release through a porous membrane, minimizing the risk of contamination and liquid spillover during fermentation. In contrast, pickle pipes rely on water traps for gas escape, which can sometimes be less reliable in preventing overflow and sealing against external air intrusion.

One-way Gas Release Membrane

One-way gas release membranes in brine bags enable controlled venting of fermentation gases without allowing oxygen ingress, preserving pickle quality and preventing spoilage. In contrast, pickle pipes, although effective for gas release, lack the precise oxygen barrier provided by one-way membranes, leading to potential contamination risks during fermentation.

Mold-resistant Ferment Cap

A mold-resistant ferment cap in a brine bag allows efficient gas release while preventing contamination during pickling, maintaining optimal anaerobic conditions. In contrast, pickle pipes facilitate gas escape but lack the same mold resistance, increasing the risk of spoilage and compromising pickle quality.

Brine bag vs Pickle pipe for gas release. Infographic

cookingdiff.com

cookingdiff.com