Glass jars provide an airtight environment that preserves the texture and flavor of pickled foods while allowing easy monitoring of the contents. Vacuum-sealed bags offer a space-saving alternative that minimizes oxygen exposure, enhancing shelf life and reducing the risk of spoilage. Choosing between them depends on storage needs, with glass jars preferred for display and vacuum-sealed bags ideal for compact, long-term preservation.

Table of Comparison

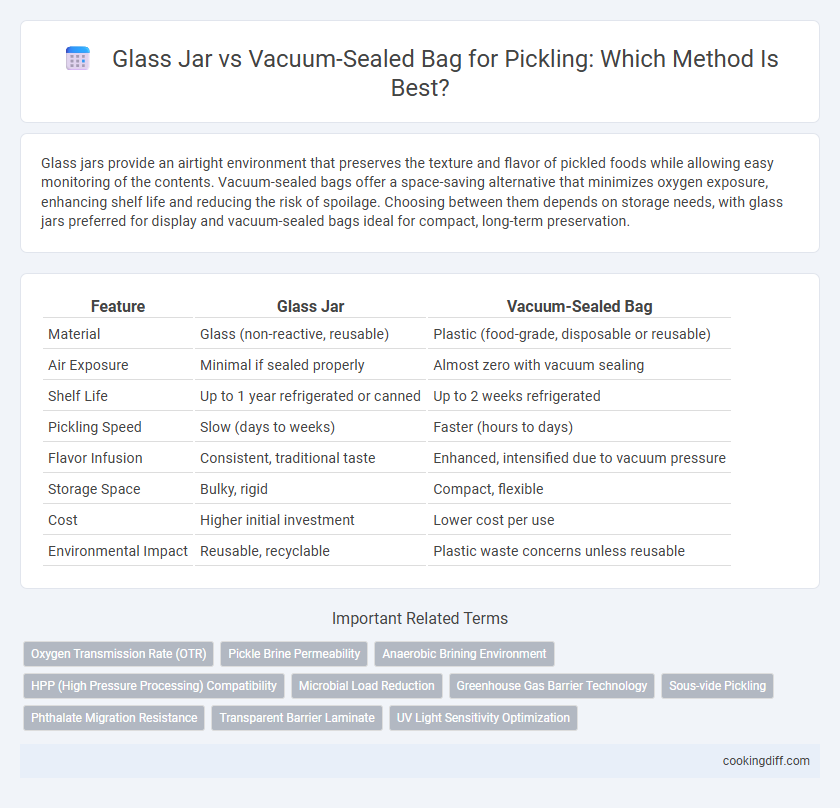

| Feature | Glass Jar | Vacuum-Sealed Bag |

|---|---|---|

| Material | Glass (non-reactive, reusable) | Plastic (food-grade, disposable or reusable) |

| Air Exposure | Minimal if sealed properly | Almost zero with vacuum sealing |

| Shelf Life | Up to 1 year refrigerated or canned | Up to 2 weeks refrigerated |

| Pickling Speed | Slow (days to weeks) | Faster (hours to days) |

| Flavor Infusion | Consistent, traditional taste | Enhanced, intensified due to vacuum pressure |

| Storage Space | Bulky, rigid | Compact, flexible |

| Cost | Higher initial investment | Lower cost per use |

| Environmental Impact | Reusable, recyclable | Plastic waste concerns unless reusable |

Overview: Glass Jars and Vacuum-Sealed Bags in Pickling

Glass jars provide an airtight seal essential for traditional pickling, preserving the texture and flavor of vegetables effectively. Their transparency allows for easy monitoring of the pickling process and the quality of the contents over time.

Vacuum-sealed bags minimize oxygen exposure better than jars, which can extend shelf life by preventing spoilage and microbial growth. These bags are flexible and space-efficient, making them ideal for bulk pickling and storage in limited refrigerator space.

Material Composition and Safety

Glass jars are composed of inert, non-reactive materials that prevent chemical interactions with acidic pickling liquids, ensuring food safety. Vacuum-sealed bags are typically made from multi-layered plastic films designed to create airtight environments but may pose risks of chemical leaching depending on the plastic type.

- Glass jar material - Made from borosilicate or soda-lime glass, offering a non-porous surface that resists acids and preserves flavor.

- Vacuum-sealed bag composition - Constructed from polyethylene, nylon, or foil layers that provide barrier properties but vary in chemical stability under acidic conditions.

- Safety considerations - Glass jars are BPA-free and do not leach substances, whereas some plastics may release harmful compounds when exposed to vinegar or salt-based brines.

Airtightness and Preservation Quality

Glass jars provide superior airtightness due to their durable lids with rubber seals, effectively preventing oxygen exposure that spoils pickled foods. This airtight environment ensures prolonged preservation quality by maintaining consistent acidity levels and flavor integrity.

Vacuum-sealed bags reduce air exposure by removing oxygen but are more susceptible to punctures that compromise seal integrity over time. While convenient for short-term storage, vacuum bags generally offer lower preservation quality compared to glass jars for long-term pickling.

Ease of Use and Accessibility

Glass jars offer a straightforward, reusable option for pickling that gives clear visibility of contents, making it easier to monitor the fermentation process. Vacuum-sealed bags require specialized equipment but save storage space and reduce air exposure, which can enhance preservation. For everyday home use, glass jars are generally more accessible and user-friendly, while vacuum-sealed bags suit those seeking compact, long-term storage solutions.

Flavor Development and Texture Differences

Glass jars provide an airtight environment that enhances flavor development by allowing natural fermentation gases to circulate without leakage, preserving the pickles' crisp texture. Vacuum-sealed bags reduce oxygen exposure more efficiently, which can intensify flavor concentration but may lead to softer textures due to lack of gas exchange. Choosing between glass jars and vacuum-sealed bags affects the balance of tanginess and crunchiness in pickled foods.

Shelf Life and Storage Considerations

Glass jars provide an airtight environment that extends pickles' shelf life up to one year when stored in a cool, dark place. Vacuum-sealed bags limit oxygen exposure but are less durable, often resulting in a shorter shelf life of around six months and requiring refrigeration.

- Glass jars are reusable and non-porous - they prevent contamination and maintain consistent acidity essential for safe long-term pickling.

- Vacuum-sealed bags are flexible and space-saving - ideal for smaller quantities but prone to punctures and degradation over time.

- Storage temperature impacts shelf life - both methods benefit from refrigeration, but glass jars tolerate room temperature storage better than vacuum-sealed bags.

Cost Comparison and Availability

| Container Type | Cost | Availability |

|---|---|---|

| Glass Jar | Higher initial investment due to reusable durable glass, averaging $2-$5 per jar | Widely available at supermarkets and online retailers, suitable for long-term storage |

| Vacuum-Sealed Bag | Lower upfront cost with disposable bags, typically $0.50-$1 per bag depending on size | Less commonly found in local stores, more accessible through specialty kitchen or online stores |

Environmental Impact and Sustainability

Which option has a lower environmental impact for pickling: glass jars or vacuum-sealed bags? Glass jars are reusable, recyclable, and have a longer lifespan, reducing waste and resource use over time. Vacuum-sealed bags, often made from single-use plastics, contribute to pollution and have limited recycling options, making glass jars the more sustainable choice for eco-conscious pickling.

Cleaning and Reusability Factors

Glass jars offer superior cleaning capabilities due to their non-porous surface, allowing thorough sterilization and preventing bacterial contamination during pickling. Vacuum-sealed bags, while convenient, are typically single-use and harder to clean effectively, increasing the risk of residue buildup and spoilage.

Glass jars can be reused multiple times without degrading quality, making them an eco-friendly and cost-effective option for pickling. Their durability withstands high-temperature sterilization processes such as boiling or dishwasher cycles. Vacuum-sealed bags, on the other hand, often need replacement after each use, limiting reusability and generating more plastic waste.

Related Important Terms

Oxygen Transmission Rate (OTR)

Glass jars provide near-zero Oxygen Transmission Rate (OTR), ensuring optimal preservation and freshness in pickling by preventing oxygen infiltration that can degrade flavor and texture. Vacuum-sealed bags, while offering low OTR, typically allow slightly higher oxygen permeability compared to glass, potentially impacting the long-term stability of pickled products.

Pickle Brine Permeability

Glass jars provide superior pickle brine permeability resistance due to their non-porous, airtight seal that prevents oxygen and contaminants from penetrating, preserving the flavor and texture of pickles longer. Vacuum-sealed bags, while reducing air exposure, may allow slight gas exchange through plastic, potentially affecting pickle brine integrity and shelf life.

Anaerobic Brining Environment

Glass jars provide an ideal anaerobic brining environment for pickling due to their airtight seal and non-reactive properties, which prevent oxygen exposure and preserve the flavor and texture of the preserved food. Vacuum-sealed bags can also reduce oxygen but may be less reliable in maintaining a consistent anaerobic environment over time, risking spoilage or off-flavors.

HPP (High Pressure Processing) Compatibility

Glass jars provide superior compatibility with High Pressure Processing (HPP) due to their rigid structure, ensuring uniform pressure application and preserving the integrity of pickled foods. Vacuum-sealed bags, while flexible and space-efficient, may risk deformation under HPP, potentially compromising the seal and reducing shelf life.

Microbial Load Reduction

Glass jars provide an airtight environment that effectively limits oxygen exposure, reducing microbial growth during pickling. Vacuum-sealed bags enhance microbial load reduction by removing air entirely, creating a low-oxygen setting that inhibits spoilage bacteria and extends the shelf life of pickled products.

Greenhouse Gas Barrier Technology

Glass jars provide an exceptional greenhouse gas barrier, preserving the pickled contents by preventing oxygen infiltration and extending shelf life without leaching chemicals. Vacuum-sealed bags incorporate advanced multilayer films with enhanced gas barrier technology, effectively minimizing greenhouse gas permeation while offering space-saving and flexible storage solutions.

Sous-vide Pickling

Glass jars provide an airtight seal and preserve the crisp texture of pickled items during sous-vide pickling, while vacuum-sealed bags enhance flavor infusion by allowing even heat distribution and minimizing oxidation. Sous-vide pickling in vacuum-sealed bags offers precise temperature control and faster marination compared to traditional glass jar methods.

Phthalate Migration Resistance

Glass jars offer superior phthalate migration resistance compared to vacuum-sealed bags, ensuring safer storage of acidic pickling solutions without the risk of harmful chemicals leaching into foods. Vacuum-sealed bags, often made from plastics containing phthalates, pose a higher risk of chemical migration during long-term pickling, especially under acidic or warm conditions.

Transparent Barrier Laminate

Glass jars provide superior preservation for pickling due to their inert, non-reactive nature and excellent oxygen barrier properties, ensuring flavor retention and preventing spoilage. Transparent barrier laminates used in vacuum-sealed bags offer convenience and flexibility but may allow minimal oxygen transmission, potentially affecting the long-term quality and shelf-life of pickled products.

Glass jar vs vacuum-sealed bag for pickling. Infographic

cookingdiff.com

cookingdiff.com