Using a plastic container for pickling offers affordability and ease of cleaning but may lack the airtight seal necessary to prevent spoilage. Anaerobic pickling vessels provide a controlled environment by eliminating oxygen, which improves fermentation quality and extends shelf life. Choosing the right container impacts flavor development and safety during the pickling process.

Table of Comparison

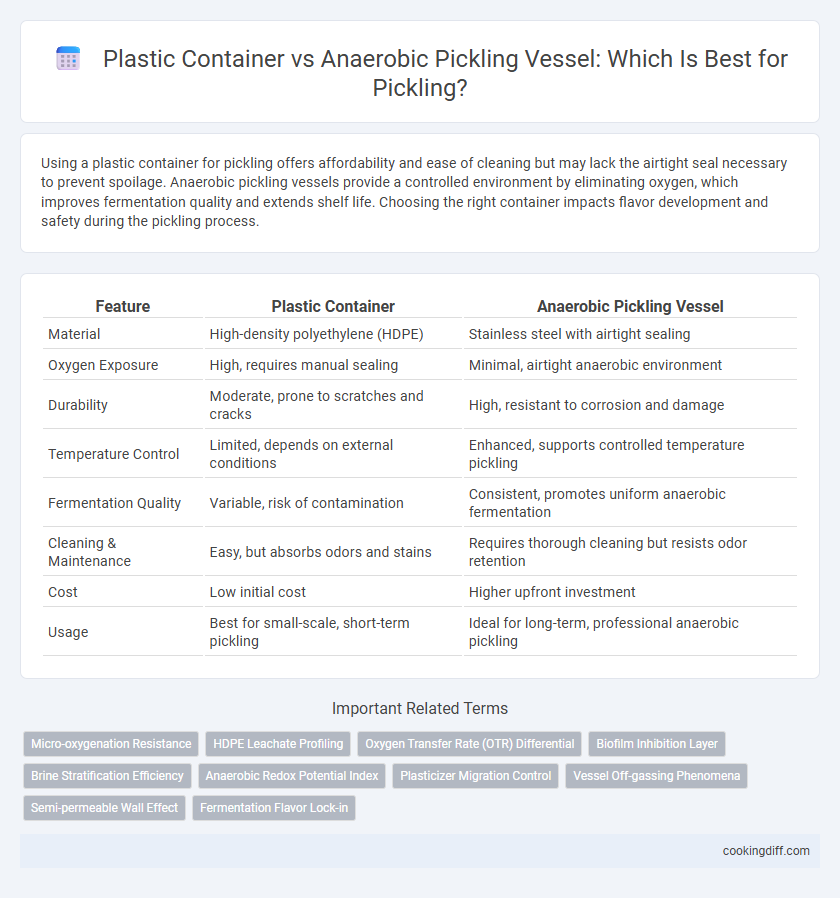

| Feature | Plastic Container | Anaerobic Pickling Vessel |

|---|---|---|

| Material | High-density polyethylene (HDPE) | Stainless steel with airtight sealing |

| Oxygen Exposure | High, requires manual sealing | Minimal, airtight anaerobic environment |

| Durability | Moderate, prone to scratches and cracks | High, resistant to corrosion and damage |

| Temperature Control | Limited, depends on external conditions | Enhanced, supports controlled temperature pickling |

| Fermentation Quality | Variable, risk of contamination | Consistent, promotes uniform anaerobic fermentation |

| Cleaning & Maintenance | Easy, but absorbs odors and stains | Requires thorough cleaning but resists odor retention |

| Cost | Low initial cost | Higher upfront investment |

| Usage | Best for small-scale, short-term pickling | Ideal for long-term, professional anaerobic pickling |

Introduction to Pickling Containers

Pickling containers play a crucial role in preserving food by facilitating the fermentation process. Plastic containers are popular for their lightweight and affordability, while anaerobic pickling vessels provide an oxygen-free environment to enhance fermentation quality.

Plastic containers are widely used due to their ease of handling and availability in various sizes, making them suitable for beginners and casual use. Anaerobic pickling vessels are designed with water-lock lids or air-tight seals that prevent air from entering, ensuring controlled fermentation and reducing the risk of spoilage. Choosing the right container depends on desired pickling outcomes, ferment volume, and the level of precision required during the process.

What is a Plastic Pickling Container?

A plastic pickling container is a food-grade, non-reactive vessel designed for fermenting and preserving vegetables through pickling. Unlike anaerobic pickling vessels, plastic containers are lightweight, transparent, and cost-effective, allowing easy monitoring of the fermentation process. They are ideal for small-batch pickling but may lack the airtight seal necessary for strictly anaerobic environments.

Understanding Anaerobic Pickling Vessels

Anaerobic pickling vessels provide a controlled oxygen-free environment essential for natural fermentation, enhancing flavor complexity and preservation. Plastic containers are less effective at maintaining strict anaerobic conditions, which may lead to inconsistent fermentation results.

- Anaerobic Environment - Anaerobic vessels prevent oxygen exposure, reducing spoilage and promoting lactic acid bacteria growth.

- Material Durability - Plastic containers can leach chemicals and may degrade over time, whereas anaerobic vessels are often made of inert materials.

- Fermentation Control - Anaerobic pickling vessels offer better temperature and gas release control, improving fermentation consistency.

Choosing an anaerobic pickling vessel is critical for achieving high-quality, safe fermented products.

Oxygen Exposure: Impact on Pickling Quality

Plastic containers often allow minimal oxygen ingress that can affect the fermentation process and lead to inferior pickling quality. Anaerobic pickling vessels are designed to eliminate oxygen exposure, preserving the crisp texture and enhancing the flavor profile of pickled products.

- Oxygen Permeability - Plastic containers may permit some oxygen penetration, potentially causing spoilage or undesirable fermentation.

- Controlled Environment - Anaerobic vessels maintain an oxygen-free environment, promoting consistent lactic acid bacteria growth for optimal pickling.

- Flavor Preservation - Reduced oxygen exposure in anaerobic vessels helps maintain bright colors and fresh flavors in pickled vegetables.

Flavor Differences: Plastic vs Anaerobic Pickling

Plastic containers tend to produce milder and less complex flavors due to oxygen exposure during pickling, which can alter the fermentation process. Anaerobic pickling vessels create richer, more intense flavors by limiting oxygen and promoting beneficial anaerobic bacterial growth.

- Milder Flavor Profile in Plastic Containers - Oxygen exposure in plastic containers results in less pronounced and subtler sourness.

- Richer Flavor in Anaerobic Vessels - Oxygen-free conditions enable stronger lactic acid fermentation, enhancing depth and tang.

- Consistency of Flavor - Anaerobic vessels offer more controlled and reproducible flavor outcomes compared to plastic containers.

Safety and Food-Grade Considerations

| Plastic Container | Food-grade plastic containers designed for pickling must be BPA-free and resistant to acidic liquids to ensure no harmful chemicals leach into the food, promoting safety and compliance with FDA guidelines. |

| Anaerobic Pickling Vessel | Typically made of glass, ceramic, or stainless steel, these vessels provide a sealed, oxygen-free environment that reduces contamination risk and fully adheres to food-grade safety standards, ensuring a safer fermentation process. |

Ease of Use and Maintenance

Plastic containers offer simplicity in handling and cleaning, making them highly accessible for home-based pickling projects. Their lightweight nature allows easy transportation and storage, though they may retain odors and stains over time.

Anaerobic pickling vessels are designed with specialized airlock systems that minimize contamination risks and maintain a controlled environment for fermentation. While they require more careful cleaning, these vessels often have durable materials and features that streamline regular maintenance for long-term use.

Cost Comparison: Plastic vs Anaerobic Vessels

Plastic containers for pickling offer a low initial investment, making them cost-effective for small-scale or hobbyist use. Anaerobic pickling vessels, although more expensive upfront, provide superior durability and a controlled environment that reduces spoilage and extends shelf life. Over time, the higher durability and efficiency of anaerobic vessels can result in lower overall costs despite the initial expense.

Longevity and Durability of Pickling Containers

Which option offers better longevity and durability for pickling containers, plastic containers or anaerobic pickling vessels? Anaerobic pickling vessels are typically constructed from high-quality, corrosion-resistant materials such as stainless steel, ensuring a longer lifespan compared to plastic containers. Plastic containers, while affordable and lightweight, are prone to cracking and chemical degradation over time, reducing their durability in long-term pickling applications.

Related Important Terms

Micro-oxygenation Resistance

Plastic containers offer basic protection but often allow micro-oxygen infiltration, which can lead to oxidation and spoilage during pickling. Anaerobic pickling vessels are specifically designed to create an oxygen-free environment, significantly enhancing micro-oxygenation resistance and preserving the quality and shelf-life of pickled products.

HDPE Leachate Profiling

HDPE plastic containers used in pickling processes often exhibit leachate profiles containing trace amounts of additives like phthalates and stabilizers, which can compromise the pickling solution's purity over time. Anaerobic pickling vessels, constructed from inert materials such as stainless steel, offer a more controlled environment that minimizes leachate contamination and preserves the chemical integrity essential for consistent pickling quality.

Oxygen Transfer Rate (OTR) Differential

Plastic containers exhibit higher Oxygen Transfer Rates (OTR) compared to anaerobic pickling vessels, leading to increased oxygen exposure that can accelerate spoilage and affect flavor development. Anaerobic pickling vessels maintain minimal OTR, creating a controlled oxygen-free environment essential for optimal fermentation and preservation of pickled products.

Biofilm Inhibition Layer

Anaerobic pickling vessels feature a specialized biofilm inhibition layer that prevents microbial growth and ensures consistent acid penetration, enhancing the safety and quality of pickled products. In contrast, standard plastic containers lack this antimicrobial barrier, leading to increased risk of biofilm formation and potential spoilage during extended fermentation.

Brine Stratification Efficiency

Anaerobic pickling vessels offer superior brine stratification efficiency by minimizing oxygen exposure and maintaining consistent salinity gradients, which helps preserve the integrity of the pickling solution and enhances microbial control. Plastic containers often suffer from uneven brine distribution and higher oxygen permeability, leading to less effective stratification and potential spoilage.

Anaerobic Redox Potential Index

Anaerobic pickling vessels maintain a stable low redox potential index, typically below -200 mV, essential for preventing oxidation and promoting effective fermentation, unlike plastic containers that often fluctuate in redox potential due to oxygen permeability. This controlled anaerobic environment ensures optimal microbial activity and consistent product quality by minimizing spoilage and off-flavors during the pickling process.

Plasticizer Migration Control

Plastic containers can risk plasticizer migration into pickled products, potentially compromising food safety and flavor integrity, whereas anaerobic pickling vessels are typically designed with inert, non-plastic materials that minimize this contamination risk. Selecting anaerobic vessels enhances control over plasticizer migration, ensuring higher product purity during the pickling process.

Vessel Off-gassing Phenomena

Plastic containers can release volatile organic compounds and off-gas harmful chemicals during anaerobic pickling, potentially affecting flavor and safety. Anaerobic pickling vessels designed with inert materials minimize off-gassing phenomena, ensuring better preservation of product quality and preventing contamination.

Semi-permeable Wall Effect

Plastic containers with semi-permeable walls allow limited gas exchange, which can influence the fermentation process by moderating oxygen exposure and preventing excessive carbon dioxide buildup. Anaerobic pickling vessels, designed to minimize gas permeability, create an optimal oxygen-free environment that enhances lactic acid bacteria activity and improves preservation quality.

Plastic Container vs Anaerobic Pickling Vessel for pickling. Infographic

cookingdiff.com

cookingdiff.com