An airlock lid offers superior control over gas release during fermentation, preventing oxygen from entering the pickling jar and reducing the risk of spoilage. Regular lids can trap gases, which may cause pressure buildup and potential jar breakage or contamination. For consistent, safe pickling, airlock lids provide a more reliable environment compared to traditional regular lids.

Table of Comparison

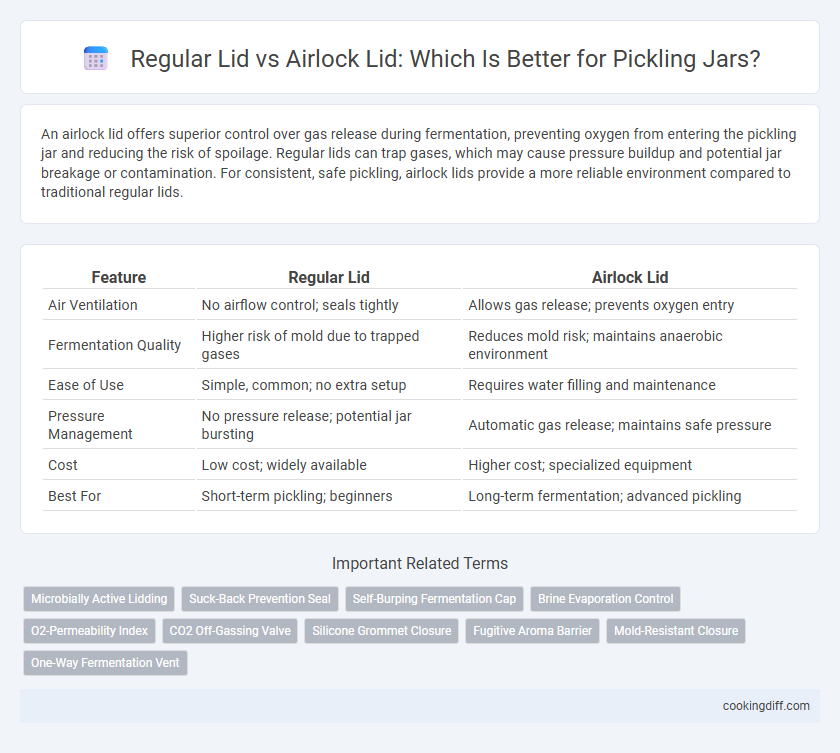

| Feature | Regular Lid | Airlock Lid |

|---|---|---|

| Air Ventilation | No airflow control; seals tightly | Allows gas release; prevents oxygen entry |

| Fermentation Quality | Higher risk of mold due to trapped gases | Reduces mold risk; maintains anaerobic environment |

| Ease of Use | Simple, common; no extra setup | Requires water filling and maintenance |

| Pressure Management | No pressure release; potential jar bursting | Automatic gas release; maintains safe pressure |

| Cost | Low cost; widely available | Higher cost; specialized equipment |

| Best For | Short-term pickling; beginners | Long-term fermentation; advanced pickling |

Introduction: The Importance of Lid Choice in Pickling

Choosing the right lid for a pickling jar is essential to ensure proper fermentation and prevent spoilage. Regular lids create a tight seal that helps maintain airtight conditions, while airlock lids allow gases to escape without letting oxygen in, reducing the risk of mold. Understanding the differences between regular and airlock lids impacts the success and safety of the pickling process.

What Is a Regular Lid?

What is a regular lid used for in pickling jars? A regular lid is a simple, airtight cover that seals the jar to preserve the contents during the pickling process. It does not allow gases to escape, making it suitable for refrigerator pickles but less ideal for fermentation that produces carbon dioxide.

Understanding Airlock Lids for Pickling

Airlock lids are designed to allow gases produced during fermentation to escape without letting oxygen in, promoting an anaerobic environment essential for safe pickling. Regular lids do not have this feature and may cause pressure build-up or spoilage due to air exposure.

- Airlock Mechanism - It features a valve or water seal that releases carbon dioxide but prevents oxygen entry.

- Pressure Regulation - Airlock lids reduce the risk of explosions by safely venting fermentation gases.

- Fermentation Quality - They help maintain optimal conditions that improve flavor and texture in pickled foods.

Using airlock lids enhances pickling success by controlling the fermentation atmosphere more effectively than regular lids.

How Each Lid Affects Fermentation

Regular lids create a sealed environment that can trap gases, potentially causing pressure buildup during fermentation. Airlock lids allow gases to escape while preventing oxygen from entering, promoting a controlled fermentation process.

- Regular lid limits gas release - Trapped gases may increase pressure and risk jar breakage.

- Airlock lid permits gas escape - Allows carbon dioxide to vent safely without oxygen exposure.

- Airlock enhances fermentation control - Reduces spoilage risk by maintaining anaerobic conditions.

Oxygen Exposure: Risks and Benefits

Regular lids on pickling jars allow minimal oxygen exposure, which can lead to faster fermentation but increases the risk of spoilage and mold growth. This oxygen presence can enhance certain flavors but requires careful monitoring to prevent contamination.

Airlock lids limit oxygen exposure by releasing gases produced during fermentation while preventing outside air from entering the jar. This controlled environment reduces spoilage risks and promotes consistent fermentation results, making it ideal for long-term pickling.

Flavor Differences: Regular Lid vs Airlock Lid

| Flavor Differences | Regular Lid | Airlock Lid |

|---|---|---|

| Fermentation Environment | Seals tightly, which can trap gases but may cause pressure buildup, sometimes affecting the taste with slight off-flavors. | Allows gases to escape through the airlock, maintaining an anaerobic environment that promotes cleaner, more consistent flavors. |

| Flavor Profile | Can develop more complex, sometimes stronger fermented notes due to limited gas release and micro-oxygen exposure. | Produces crisp, fresher flavors by minimizing oxygen exposure and preventing contamination during fermentation. |

Mold and Contamination Concerns

Regular lids for pickling jars can sometimes trap air and moisture, creating conditions that promote mold growth and contamination. Airlock lids allow gases to escape while preventing oxygen and contaminants from entering, reducing the risk of spoilage.

Using an airlock lid significantly lowers the chance of mold by maintaining an anaerobic environment essential for safe fermentation. Regular lids may require frequent monitoring to avoid contamination caused by trapped air. Proper sealing with an airlock lid ensures a more consistent and reliable pickling process.

Ease of Use: Comparing Lid Types

Regular lids for pickling jars offer straightforward application and secure sealing, making them suitable for beginners and quick preservation tasks. Airlock lids provide controlled gas release during fermentation, reducing the risk of jar explosions and ensuring consistent pickling results. While airlock lids require initial setup, their ease of monitoring fermentation progress makes them preferred for advanced picklers seeking precision and safety.

Cost and Availability: Which Lid Is More Practical?

Regular lids for pickling jars are widely available and generally cost less, making them an affordable option for most home canners. These lids can be easily found in supermarkets and online, providing convenience for quick pickling projects.

Airlock lids, while more expensive and less commonly stocked, offer precise gas release control essential for fermentation. Their higher cost and limited availability may pose challenges for casual picklers but benefit those focused on consistent, high-quality fermentation results.

Related Important Terms

Microbially Active Lidding

Microbially active lidding in pickling jars varies significantly between regular lids and airlock lids, with airlock lids promoting a controlled anaerobic environment ideal for fermentative microbial activity. Regular lids often trap gases and moisture, risking spoilage and off-flavors due to uncontrolled microbial growth during fermentation.

Suck-Back Prevention Seal

An airlock lid for pickling jars provides superior suck-back prevention by allowing gases to escape without letting air back in, which maintains an anaerobic environment essential for proper fermentation. Regular lids often fail to prevent suck-back, risking contamination and spoilage by allowing oxygen to re-enter the jar during cooling.

Self-Burping Fermentation Cap

The Self-Burping Fermentation Cap offers a convenient alternative to regular lids and airlock lids by automatically releasing gas buildup while preventing oxygen exposure, ensuring optimal anaerobic fermentation conditions. Its innovative design simplifies the pickling process, reduces the risk of jar explosions, and maintains consistent flavor and texture without the need for manual burping.

Brine Evaporation Control

Airlock lids minimize brine evaporation by allowing gases to escape while preventing oxygen from entering, maintaining optimal anaerobic conditions for fermentation. Regular lids can trap pressure or allow unwanted air exchange, leading to inconsistent brine levels and potential spoilage.

O2-Permeability Index

Regular lids for pickling jars have a high O2-Permeability Index, allowing more oxygen to enter and potentially causing faster spoilage or oxidation of the contents. Airlock lids feature a low O2-Permeability Index, creating an anaerobic environment that preserves flavor and extends shelf life by minimizing oxygen exposure.

CO2 Off-Gassing Valve

A regular lid on a pickling jar can trap CO2 produced during fermentation, increasing pressure and risking jar breakage, while an airlock lid with a CO2 off-gassing valve allows excess gas to escape safely, maintaining anaerobic conditions and preventing contamination. This specialized valve is essential for controlled fermentation, ensuring consistent flavor development and preserving the texture of pickled foods.

Silicone Grommet Closure

The silicone grommet closure in airlock lids provides an airtight seal that allows carbon dioxide to escape during fermentation while preventing oxygen and contaminants from entering, ensuring optimal anaerobic conditions for pickling. Regular lids lack this feature, often resulting in pressure buildup or spoilage due to trapped gases and exposure to air.

Fugitive Aroma Barrier

Airlock lids provide a superior fugitive aroma barrier by allowing gases to escape while preventing oxygen and contaminants from entering, which helps preserve the pickling brine's volatile flavors. Regular lids, lacking this controlled ventilation, often trap carbon dioxide and moisture, leading to compromised aroma retention and potentially off-flavors.

Mold-Resistant Closure

Regular lids for pickling jars often lack specialized seals, increasing the risk of mold growth due to air exposure, while airlock lids create a controlled anaerobic environment that significantly reduces mold formation. Using an airlock lid with a silicone or rubber gasket enhances mold-resistant closure by allowing gas to escape without letting oxygen or contaminants enter the jar.

Regular lid vs Airlock lid for pickling jar. Infographic

cookingdiff.com

cookingdiff.com