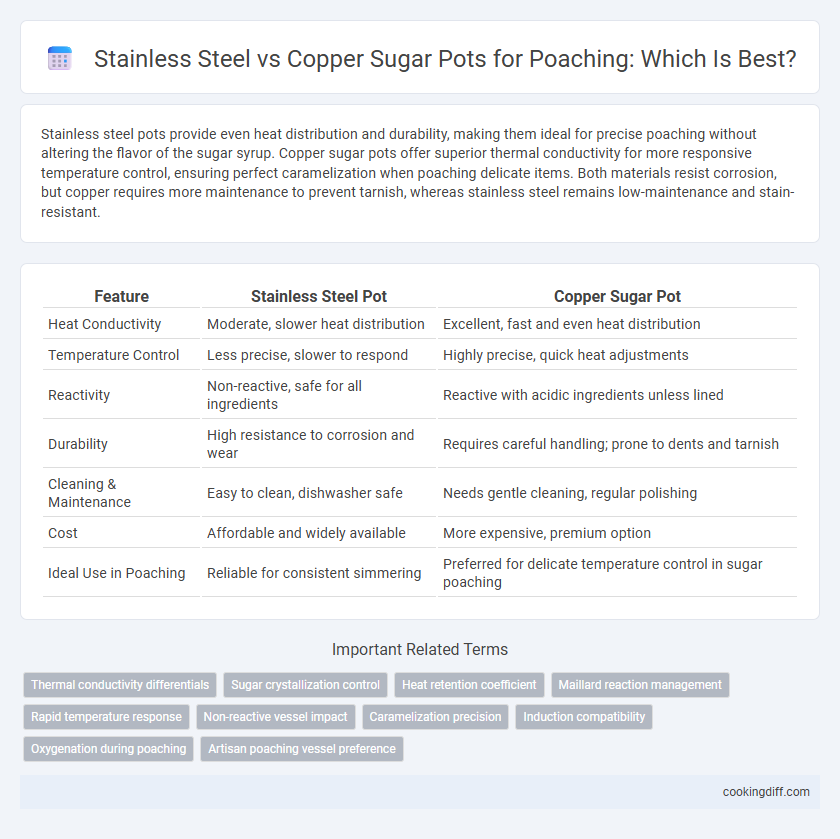

Stainless steel pots provide even heat distribution and durability, making them ideal for precise poaching without altering the flavor of the sugar syrup. Copper sugar pots offer superior thermal conductivity for more responsive temperature control, ensuring perfect caramelization when poaching delicate items. Both materials resist corrosion, but copper requires more maintenance to prevent tarnish, whereas stainless steel remains low-maintenance and stain-resistant.

Table of Comparison

| Feature | Stainless Steel Pot | Copper Sugar Pot |

|---|---|---|

| Heat Conductivity | Moderate, slower heat distribution | Excellent, fast and even heat distribution |

| Temperature Control | Less precise, slower to respond | Highly precise, quick heat adjustments |

| Reactivity | Non-reactive, safe for all ingredients | Reactive with acidic ingredients unless lined |

| Durability | High resistance to corrosion and wear | Requires careful handling; prone to dents and tarnish |

| Cleaning & Maintenance | Easy to clean, dishwasher safe | Needs gentle cleaning, regular polishing |

| Cost | Affordable and widely available | More expensive, premium option |

| Ideal Use in Poaching | Reliable for consistent simmering | Preferred for delicate temperature control in sugar poaching |

Introduction to Poaching: Choosing the Right Pot

Poaching requires precise temperature control to achieve delicate cooking results, making the choice of pot crucial. Stainless steel and copper sugar pots offer distinct benefits that impact heat distribution and cooking performance.

- Stainless Steel Pot - Durable and non-reactive, it provides even heating suitable for gentle poaching.

- Copper Sugar Pot - Excellent thermal conductivity ensures rapid and precise temperature adjustments during poaching.

- Heat Control - Copper pots excel in maintaining consistent low temperatures, ideal for delicate ingredients in poaching.

Stainless Pot: Features and Benefits for Poaching

Stainless steel pots provide even heat distribution and excellent durability, making them ideal for consistent poaching results. Their non-reactive surface ensures food flavors remain pure without metallic aftertaste.

- Corrosion Resistance - Stainless steel resists rust and stains, extending the pot's lifespan in humid kitchen environments.

- Easy Maintenance - The smooth surface of stainless steel simplifies cleaning and prevents food from sticking during poaching.

- Heat Retention - Stainless steel maintains stable temperature control, essential for gentle and precise poaching processes.

These features make stainless steel pots a reliable and efficient choice for poaching delicate ingredients.

Copper Sugar Pot: Features and Advantages in Poaching

Copper sugar pots offer superior heat conductivity, ensuring precise temperature control essential for perfect poaching. Their rapid heat response prevents overcooking, preserving the texture and flavor of delicate ingredients. The elegant design and durability of copper pots also make them a preferred choice for professional kitchens focused on quality and presentation.

Heat Conductivity: Stainless vs Copper for Even Cooking

| Material | Heat Conductivity (W/m*K) | Cooking Performance |

| Stainless Steel | 16 | Heats slowly and unevenly, often requiring additional heat control for consistent poaching. |

| Copper | 401 | Offers superior heat conductivity for precise, even cooking ideal for delicate poaching tasks. |

Temperature Control: Precision in Each Pot Type

Stainless steel pots provide consistent heat distribution, allowing for precise temperature control essential in poaching delicate ingredients. Copper sugar pots offer superior thermal conductivity, enabling rapid temperature adjustments but require careful monitoring to maintain stability. Both materials influence poaching outcomes, with stainless steel favoring even cooking and copper excelling in responsive heat management.

Reactivity with Ingredients: Safety and Flavor Implications

Stainless steel pots are non-reactive and maintain the purity of flavors in poaching ingredients, ensuring safety and consistent taste. Copper sugar pots, while excellent conductors of heat, can react with acidic ingredients, potentially altering flavors and raising safety concerns if not properly lined.

- Stainless steel is non-reactive - it prevents any metallic taste or chemical interaction with food during poaching.

- Copper pots react with acids - acidic poaching liquids may cause copper to leach, impacting both flavor and safety.

- Proper lining matters - copper pots require a tin or stainless lining to ensure safe, non-reactive cooking surfaces.

Maintenance and Durability: Stainless versus Copper Pots

Which material offers better maintenance and durability for poaching, stainless steel or copper sugar pots? Stainless steel pots are highly resistant to rust, corrosion, and staining, making them easier to clean and maintain over time. Copper pots provide superior heat conductivity but require regular polishing and careful handling to prevent tarnishing and maintain their durability.

Price Comparison: Cost Efficiency in Poaching Pots

Stainless steel pots generally offer a more cost-effective option for poaching compared to copper sugar pots, which tend to be significantly more expensive due to their superior heat conductivity and craftsmanship. The higher initial investment in copper pots can be a deterrent for budget-conscious buyers seeking durable poaching equipment.

Despite the higher price, copper sugar pots provide precise temperature control, essential for delicate poaching tasks, which can improve cooking results and efficiency. Stainless steel pots, although less expensive, may require longer heating times and less uniform heat distribution. Choosing between the two depends on the balance between upfront cost and desired cooking performance in poaching applications.

Best Uses: When to Choose Stainless or Copper for Poaching

Stainless steel pots are ideal for poaching delicate foods like fish and eggs due to their non-reactive surface and even heat distribution, preventing flavor alteration. Copper sugar pots offer superior thermal conductivity, allowing precise temperature control, which is essential for poaching sugar-based syrups or custards.

Choose stainless steel when durability and ease of maintenance are priorities, as it resists corrosion and staining during frequent poaching. Opt for copper pots when temperature sensitivity and consistent heat are crucial, especially in recipes requiring gradual temperature adjustments.

Related Important Terms

Thermal conductivity differentials

Copper sugar pots offer superior thermal conductivity, heating rapidly and distributing heat evenly for precise temperature control in poaching. Stainless pots have lower thermal conductivity, resulting in slower, less uniform heat distribution that can cause uneven cooking during the poaching process.

Sugar crystallization control

Stainless steel pots offer superior control over sugar crystallization during poaching due to their non-reactive surface and even heat distribution, preventing caramelization and graininess. Copper sugar pots provide rapid, precise temperature adjustments critical for maintaining syrup consistency but require constant stirring to avoid crystallization and reactive flavor changes.

Heat retention coefficient

Stainless steel pots exhibit a lower heat retention coefficient compared to copper sugar pots, resulting in faster heat dissipation and less consistent temperature control during poaching. Copper sugar pots, with their superior thermal conductivity and higher heat retention coefficient, provide more even heat distribution and stable temperatures, crucial for precise poaching techniques.

Maillard reaction management

Stainless steel pots offer better control over the Maillard reaction during poaching due to their even heat distribution and non-reactive surface, preventing unwanted browning and metallic taste. Copper sugar pots provide superior thermal conductivity, allowing precise temperature adjustments that facilitate optimal Maillard reaction management, but require careful monitoring to avoid burning.

Rapid temperature response

Stainless steel pots offer slower heat conduction compared to copper sugar pots, resulting in less rapid temperature response during poaching. Copper sugar pots excel in quickly adjusting to temperature changes, providing precise control crucial for delicate poaching techniques.

Non-reactive vessel impact

Stainless steel pots provide a non-reactive cooking surface that preserves the pure flavor and color of poached ingredients, preventing metallic taste contamination often associated with reactive metals. Copper sugar pots, while excellent for heat conductivity, can react with acidic poaching liquids, potentially causing discoloration and off-flavors, making stainless steel the preferred choice for consistent, high-quality poaching results.

Caramelization precision

Copper sugar pots provide superior heat conductivity for precise caramelization control during poaching, ensuring even temperature distribution and reducing the risk of burning. Stainless steel pots, while durable and resistant to corrosion, offer less responsive heat control, which can lead to uneven caramelization and affect the quality of the final poached product.

Induction compatibility

Stainless pots offer superior induction compatibility due to their magnetic properties, ensuring efficient and even heating during poaching. Copper sugar pots typically lack induction compatibility unless specifically designed with a magnetic base, which can limit their usability on induction cooktops.

Oxygenation during poaching

Copper sugar pots enhance oxygenation during poaching due to their superior heat conductivity and reactive surface, promoting better flavor development and texture in poached foods. Stainless steel pots, while durable and non-reactive, offer less efficient heat distribution, resulting in slower oxygen release and potentially less vibrant poaching outcomes.

Stainless pot vs Copper sugar pot for poaching. Infographic

cookingdiff.com

cookingdiff.com