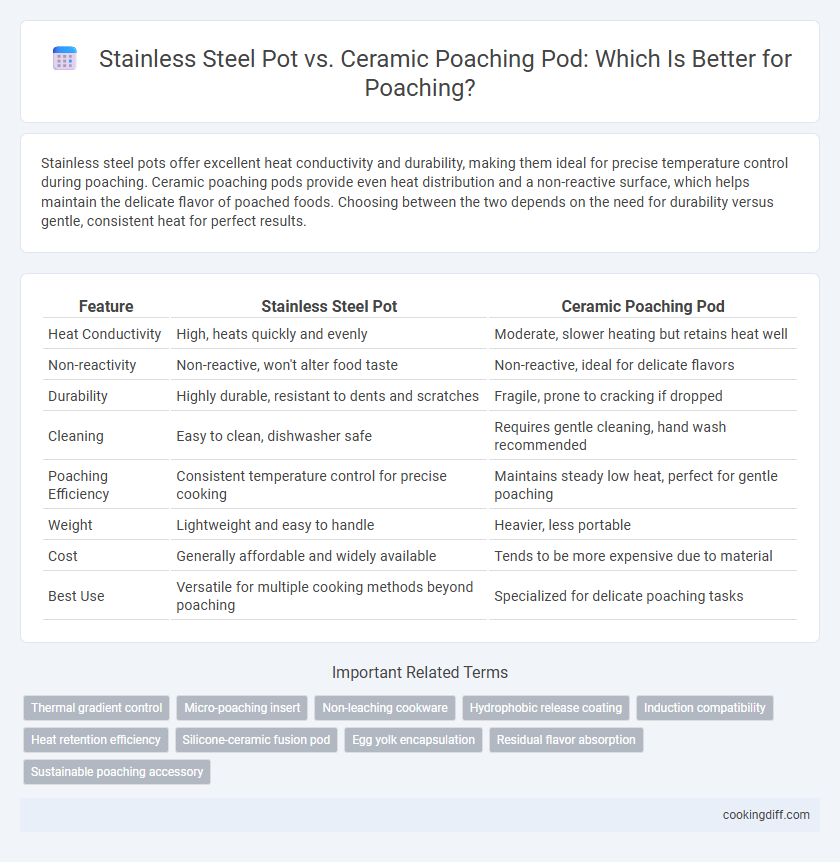

Stainless steel pots offer excellent heat conductivity and durability, making them ideal for precise temperature control during poaching. Ceramic poaching pods provide even heat distribution and a non-reactive surface, which helps maintain the delicate flavor of poached foods. Choosing between the two depends on the need for durability versus gentle, consistent heat for perfect results.

Table of Comparison

| Feature | Stainless Steel Pot | Ceramic Poaching Pod |

|---|---|---|

| Heat Conductivity | High, heats quickly and evenly | Moderate, slower heating but retains heat well |

| Non-reactivity | Non-reactive, won't alter food taste | Non-reactive, ideal for delicate flavors |

| Durability | Highly durable, resistant to dents and scratches | Fragile, prone to cracking if dropped |

| Cleaning | Easy to clean, dishwasher safe | Requires gentle cleaning, hand wash recommended |

| Poaching Efficiency | Consistent temperature control for precise cooking | Maintains steady low heat, perfect for gentle poaching |

| Weight | Lightweight and easy to handle | Heavier, less portable |

| Cost | Generally affordable and widely available | Tends to be more expensive due to material |

| Best Use | Versatile for multiple cooking methods beyond poaching | Specialized for delicate poaching tasks |

Introduction: Poaching Techniques and Tools

| Stainless steel pots offer superior heat conductivity and durability, making them ideal for consistent temperature control during poaching. Ceramic poaching pods provide non-reactive surfaces that prevent metal taste impartation and enhance aesthetic appeal. Selecting the appropriate tool depends on heat retention, ease of cleaning, and the type of food being poached for optimal results. |

Overview of Stainless Steel Pots for Poaching

Stainless steel pots provide excellent heat conductivity and durability, making them a reliable choice for poaching delicate foods. Their non-reactive surface ensures that flavors remain pure without imparting any metallic taste. These pots typically feature a sturdy construction and easy-to-clean finish, ideal for consistent temperature control during the poaching process.

Ceramic Poaching Pods: Features and Benefits

Ceramic poaching pods offer superior heat retention and even distribution, ensuring delicate foods cook gently and uniformly. Unlike stainless steel pots, ceramic pods reduce the risk of sticking and preserve the natural flavors of poached ingredients.

- Heat Retention - Ceramic material maintains consistent temperature for precise cooking control.

- Non-stick Surface - Minimizes food adhesion, making cleanup easier and preserving food texture.

- Flavor Preservation - Inert ceramic prevents metallic taste infusion, enhancing the natural flavor of poached dishes.

Heat Distribution: Stainless Steel vs Ceramic Pods

Stainless steel pots provide rapid and even heat distribution, reducing hot spots that can cause uneven cooking during poaching. Ceramic poaching pods excel in heat retention, maintaining a consistent temperature for delicate items like eggs. The choice between stainless steel and ceramic depends on whether quick temperature adjustments or sustained gentle heat is more critical for poaching success.

Ease of Use and Convenience

Stainless steel pots offer durability and quick heat conduction, making them easy to control during poaching. Their non-reactive surface allows for effortless cleaning and maintenance after use.

Ceramic poaching pods provide a non-stick surface that prevents eggs from sticking and promotes even cooking. Their lightweight design enhances maneuverability, but they require gentle handling to avoid chipping.

Cleaning and Maintenance Comparison

Stainless steel pots offer easier cleaning due to their smooth, non-porous surfaces, making them less prone to staining and residue buildup. Ceramic poaching pods require gentle handling and specific detergents to prevent surface damage and maintain their non-stick quality.

- Durability - Stainless steel resists scratching and can withstand abrasive cleaners without damage.

- Porosity - Ceramic surfaces can absorb oils and odors if not cleaned promptly.

- Maintenance - Ceramic pods need careful drying to avoid moisture retention and potential cracking.

Overall, stainless steel pots demand less intensive maintenance, making them more practical for frequent use in poaching.

Poaching Results: Texture and Flavor Differences

Stainless steel pots retain heat evenly, allowing precise temperature control that results in tender, consistently poached eggs with a clean, neutral flavor. Ceramic poaching pods provide a gentle, slow heat distribution, preserving delicate textures and enhancing subtle flavors through minimal thermal shock.

Ceramic pods absorb and diffuse heat gradually, reducing the risk of overcooking and producing creamier yolks with a richer mouthfeel. Stainless steel's rapid heat conduction can sometimes cause slight rubberiness if not carefully monitored, but it excels in maintaining a clear, pure poach. Both methods yield excellent results, with ceramic favoring texture softness and stainless steel emphasizing flavor clarity.

Durability and Longevity

Which material offers better durability and longevity for poaching between a stainless steel pot and a ceramic poaching pod? Stainless steel pots are highly resistant to corrosion, scratches, and thermal shock, making them ideal for frequent use and long-term durability. Ceramic poaching pods, while providing even heat distribution, are more susceptible to chipping and cracking over time, reducing their overall lifespan compared to stainless steel.

Cost Considerations: Which Is More Economical?

Stainless steel pots typically cost less upfront than ceramic poaching pods, offering durability that reduces replacement frequency. Their heat-conductive properties allow for efficient cooking, which may save energy costs over time.

Ceramic poaching pods often have a higher initial price but provide even heat distribution, enhancing food texture and flavor during poaching. Long-term care and careful handling are required to maintain ceramics, potentially increasing upkeep expenses compared to stainless steel.

Related Important Terms

Thermal gradient control

Stainless steel pots offer superior thermal gradient control due to their excellent heat conductivity and even heat distribution, minimizing temperature fluctuations during poaching. Ceramic poaching pods, while aesthetically pleasing and retaining heat well, often exhibit slower temperature adjustments, which can result in less precise control over the poaching temperature.

Micro-poaching insert

Micro-poaching inserts made from stainless steel offer superior heat conductivity and durability compared to ceramic poaching pods, ensuring even cooking temperatures for delicate foods. These stainless steel inserts resist cracking and maintain their shape under high heat, making them ideal for consistent poaching results and easy cleaning.

Non-leaching cookware

Stainless steel pots offer a durable, non-reactive surface that prevents leaching of harmful chemicals or metals into food, ensuring safe poaching results. Ceramic poaching pods provide a naturally non-toxic, non-leaching option with excellent heat retention, ideal for preserving the purity and flavor of delicate poached ingredients.

Hydrophobic release coating

Stainless steel pots with hydrophobic release coatings offer superior non-stick surfaces for poaching, minimizing food adherence and facilitating easy cleanup compared to ceramic poaching pods. The advanced hydrophobic layer enhances heat distribution and durability, making stainless steel an efficient choice for consistent poaching performance.

Induction compatibility

Stainless steel pots offer superior induction compatibility due to their magnetic base, ensuring efficient heat transfer and precise temperature control for poaching. Ceramic poaching pods often lack magnetic properties, making them incompatible with induction cooktops and limiting their effectiveness in maintaining consistent cooking temperatures.

Heat retention efficiency

Stainless steel pots excel in heat retention efficiency due to their dense metal composition, allowing consistent and even heat distribution essential for precise poaching temperatures. Ceramic poaching pods, while aesthetically pleasing, typically have lower thermal conductivity and slower heat response, which can lead to uneven cooking and longer heat-up times.

Silicone-ceramic fusion pod

Silicone-ceramic fusion pods combine the non-reactive, scratch-resistant properties of ceramic with the heat-resistant flexibility of silicone, offering superior temperature control and easy food release during poaching compared to stainless steel pots. Their lightweight design and non-stick surface enhance convenience and reduce cleanup time, making them an efficient choice for delicate poaching tasks.

Egg yolk encapsulation

Stainless steel pots provide consistent heat distribution that allows precise control during egg poaching, promoting better yolk encapsulation by preventing rapid temperature fluctuations. Ceramic poaching pods offer a non-reactive surface and gentle heat retention, which helps maintain the egg yolk's integrity and prevents overcooking or breaking during the poaching process.

Residual flavor absorption

Stainless steel pots resist residual flavor absorption due to their non-porous surface, ensuring pure, untainted flavors with each poaching session. Ceramic poaching pods, while gentle on food, tend to absorb and retain flavors over time, which can subtly alter the taste of delicate dishes.

Stainless steel pot vs Ceramic poaching pod for poaching. Infographic

cookingdiff.com

cookingdiff.com