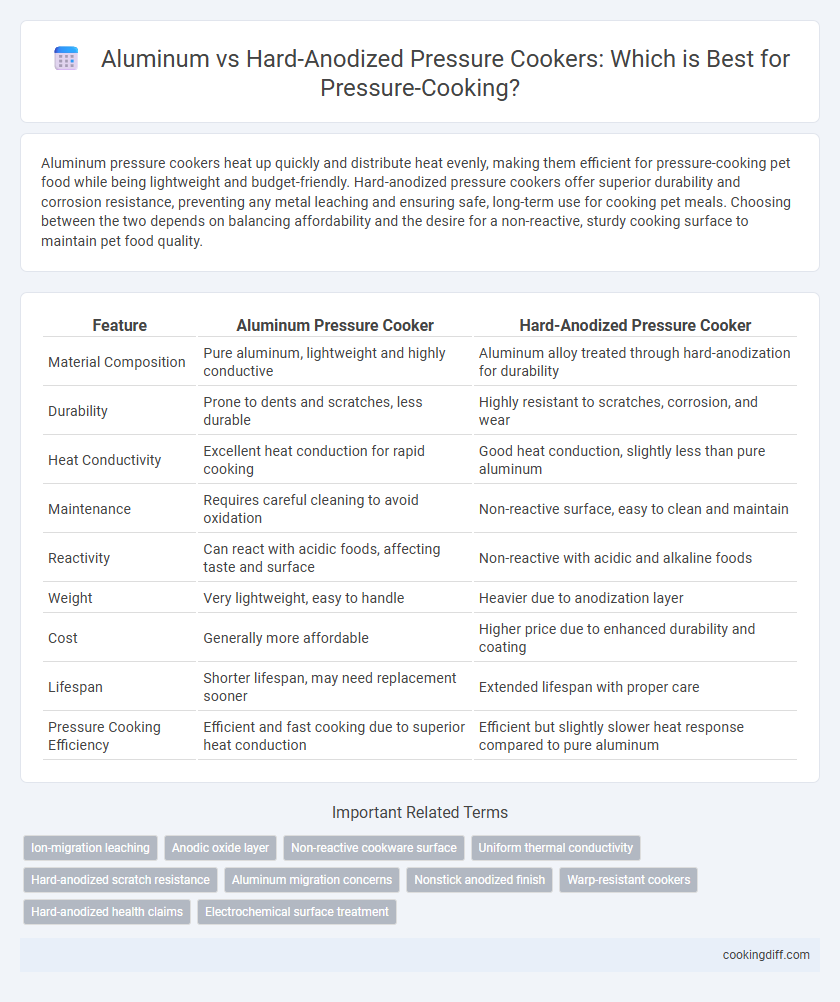

Aluminum pressure cookers heat up quickly and distribute heat evenly, making them efficient for pressure-cooking pet food while being lightweight and budget-friendly. Hard-anodized pressure cookers offer superior durability and corrosion resistance, preventing any metal leaching and ensuring safe, long-term use for cooking pet meals. Choosing between the two depends on balancing affordability and the desire for a non-reactive, sturdy cooking surface to maintain pet food quality.

Table of Comparison

| Feature | Aluminum Pressure Cooker | Hard-Anodized Pressure Cooker |

|---|---|---|

| Material Composition | Pure aluminum, lightweight and highly conductive | Aluminum alloy treated through hard-anodization for durability |

| Durability | Prone to dents and scratches, less durable | Highly resistant to scratches, corrosion, and wear |

| Heat Conductivity | Excellent heat conduction for rapid cooking | Good heat conduction, slightly less than pure aluminum |

| Maintenance | Requires careful cleaning to avoid oxidation | Non-reactive surface, easy to clean and maintain |

| Reactivity | Can react with acidic foods, affecting taste and surface | Non-reactive with acidic and alkaline foods |

| Weight | Very lightweight, easy to handle | Heavier due to anodization layer |

| Cost | Generally more affordable | Higher price due to enhanced durability and coating |

| Lifespan | Shorter lifespan, may need replacement sooner | Extended lifespan with proper care |

| Pressure Cooking Efficiency | Efficient and fast cooking due to superior heat conduction | Efficient but slightly slower heat response compared to pure aluminum |

Introduction to Pressure Cookers: Aluminum vs Hard-Anodized

| Material | Aluminum | Hard-Anodized Aluminum |

| Durability | Soft and prone to scratches and dents | Harder surface, scratch-resistant and longer-lasting |

| Heat Conductivity | Excellent heat conduction for fast cooking | Good heat conduction, slightly less than pure aluminum |

| Non-Stick Properties | No inherent non-stick surface | Typically features a non-stick coating for easy cleaning |

| Reactivity | Can react with acidic foods, affecting flavor and finish | Non-reactive surface, more suitable for diverse recipes |

| Weight | Lightweight and easy to handle | Slightly heavier due to anodized coating |

Material Composition: Aluminum vs Hard-Anodized Pressure Cookers

Aluminum pressure cookers are lightweight and offer excellent heat conductivity, making them ideal for quick and even cooking. Hard-anodized pressure cookers feature a durable, non-reactive surface created through electrochemical treatment, enhancing resistance to scratches and corrosion.

- Aluminum Core - Provides superior thermal conductivity but can react with acidic foods, potentially affecting taste and safety.

- Hard-Anodized Surface - Creates a protective layer that prevents aluminum from leaching into food and ensures long-term durability.

- Material Strength - Hard-anodized cookers are generally more resistant to dents and warping compared to standard aluminum models.

Choosing between aluminum and hard-anodized pressure cookers depends on priorities such as cooking performance, maintenance, and longevity.

Durability and Longevity Comparison

Aluminum pressure cookers are lightweight and conduct heat efficiently but tend to scratch and dent easily, which can reduce their lifespan. Hard-anodized pressure cookers feature a tougher surface that resists corrosion and wear, providing enhanced durability over time.

- Aluminum is prone to surface degradation - Repeated use and cleaning can cause aluminum cookers to lose their smooth finish and structural integrity.

- Hard-anodized coating offers superior scratch resistance - This surface treatment makes the cooker more resistant to abrasion and physical damage.

- Longevity of hard-anodized pressure cookers is generally greater - They maintain performance and appearance longer than standard aluminum models under regular use.

Heat Conductivity and Cooking Performance

Aluminum pressure cookers offer superior heat conductivity, allowing for faster heat distribution and efficient cooking performance. Hard-anodized pressure cookers provide excellent durability and even heat retention, contributing to consistent pressure cooking results.

- Aluminum Pressure Cooker Heat Conductivity - Aluminum's high thermal conductivity ensures rapid and uniform heat spread throughout the cooking chamber.

- Hard-Anodized Pressure Cooker Durability - The hard-anodized surface resists scratches and corrosion, enhancing long-term cooking efficiency.

- Cooking Performance Comparison - Aluminum excels in quick heating, while hard-anodized models deliver steady heat retention for precise pressure control.

Safety Features: Which is Safer for Pressure-Cooking?

Aluminum pressure cookers are lightweight and conduct heat efficiently but may warp under high pressure and frequent use, posing potential safety risks. They often lack advanced locking mechanisms, increasing the chance of accidental lid release during cooking.

Hard-anodized pressure cookers feature a durable, non-reactive surface with reinforced safety valves and secure locking lids, minimizing the risk of accidents. Their enhanced structural integrity makes them safer choices for pressure-cooking, especially at higher pressure levels and prolonged use.

Maintenance and Cleaning: Ease of Use

Aluminum pressure cookers require frequent polishing to prevent discoloration and maintain their shiny appearance, making maintenance slightly more demanding. Hard-anodized pressure cookers feature a durable, non-reactive surface that resists stains and scratches, significantly simplifying cleaning and upkeep. Both materials are dishwasher-safe, but hard-anodized options minimize the need for abrasive cleaners, enhancing ease of use during pressure-cooking.

Health and Food Safety: Potential Risks and Benefits

Aluminum pressure cookers are lightweight and conduct heat efficiently but may pose health risks due to aluminum leaching into acidic foods, which has been associated with potential neurological concerns. Hard-anodized pressure cookers feature a chemically hardened surface that resists corrosion and prevents metal transfer, ensuring safer cooking for acidic and long-duration pressure-cooking tasks.

Hard-anodized cookware offers better durability and non-reactivity, reducing the risk of food contamination and preserving flavor and nutrient integrity during high-pressure cooking. Choosing a non-reactive pressure cooker material like hard-anodized aluminum can enhance food safety and minimize exposure to harmful metal ions commonly linked to conventional aluminum pressure cookers.

Price Comparison: Affordability and Value

Aluminum pressure cookers are generally more affordable, making them an attractive option for budget-conscious buyers. Hard-anodized pressure cookers are priced higher due to their enhanced durability, corrosion resistance, and non-stick properties. The added cost of hard-anodized models often provides better long-term value through increased lifespan and improved cooking performance.

Suitability for Different Cuisines and Recipes

Aluminum pressure cookers are ideal for Indian and other South Asian cuisines that require rapid heat conduction for dishes like dals and curries, ensuring even cooking and shorter pressure times. Hard-anodized pressure cookers are better suited for Western recipes involving longer cooking durations and acidic ingredients, as their durable surface prevents corrosion and maintains flavor integrity.

Recipes with delicate flavors or longer cooking times benefit from hard-anodized pressure cookers due to their resistance to scratching and staining, which helps avoid metallic tastes. Aluminum models excel in quick-cooking recipes where heat responsiveness and lightweight construction enhance ease of use. Choosing between these materials depends on the primary cuisine and cooking techniques regularly employed in pressure-cooking.

Related Important Terms

Ion-migration leaching

Aluminum pressure cookers are prone to ion-migration leaching, which can introduce aluminum ions into acidic or salty food, potentially affecting taste and health. Hard-anodized pressure cookers feature a chemically treated surface that significantly reduces ion migration, ensuring safer and more durable cooking performance.

Anodic oxide layer

Hard-anodized pressure cookers feature a durable anodic oxide layer that enhances corrosion resistance and prevents aluminum leaching, making them safer and more long-lasting for pressure-cooking compared to standard aluminum pressure cookers. This oxide layer also provides superior non-reactive surfaces, ensuring food flavor integrity and easy cleaning during high-temperature pressure-cooking processes.

Non-reactive cookware surface

Aluminum pressure cookers heat quickly but may react with acidic foods, altering taste and discoloring the cookware, while hard-anodized pressure cookers feature a non-reactive, durable surface that preserves food flavor and prevents corrosion. Hard-anodized surfaces provide enhanced resistance to scratches and chemical reactions, making them ideal for maintaining food integrity during pressure-cooking.

Uniform thermal conductivity

Aluminum pressure cookers offer superior uniform thermal conductivity, ensuring even heat distribution for consistent cooking results. Hard-anodized pressure cookers, while more durable and resistant to corrosion, have slightly less uniform heat transfer compared to aluminum, which may affect cooking efficiency.

Hard-anodized scratch resistance

Hard-anodized pressure cookers offer superior scratch resistance due to their durable, non-porous surface formed through an electrochemical anodizing process. Unlike aluminum pressure cookers, which can dent and scratch more easily, hard-anodized models maintain their structural integrity and appearance even with frequent use and rigorous cleaning.

Aluminum migration concerns

Aluminum pressure cookers, while lightweight and conductive, raise concerns about aluminum migration into food, especially when cooking acidic ingredients, which can pose potential health risks. Hard-anodized pressure cookers feature a non-reactive, durable surface that prevents aluminum leaching, making them a safer choice for minimizing chemical exposure during pressure cooking.

Nonstick anodized finish

Hard-anodized pressure cookers feature a durable, nonstick anodized finish that resists corrosion and prevents food from sticking, ensuring easier cleaning and longer-lasting performance. Aluminum pressure cookers, while lightweight and quick to heat, typically lack this advanced nonstick surface, making them more prone to scratches and reduced nonstick effectiveness over time.

Warp-resistant cookers

Hard-anodized pressure cookers offer superior warp resistance compared to aluminum pressure cookers due to their reinforced surface and enhanced durability. This makes hard-anodized models more reliable for consistent pressure-cooking performance and longer lifespan under high heat conditions.

Hard-anodized health claims

Hard-anodized pressure cookers feature a dense, non-reactive surface created through an electrochemical process, preventing aluminum leaching and ensuring safer food preparation compared to standard aluminum pressure cookers. This enhanced durability and resistance to corrosion reduce the risk of metal contamination, making hard-anodized pressure cookers a preferred choice for health-conscious pressure-cooking.

Aluminum pressure cooker vs hard-anodized pressure cooker for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com