Weighted gauge pressure cookers rely on a simple mechanical system that maintains consistent pressure by allowing excess steam to escape through a weighted valve, ensuring reliability and ease of use without the need for electricity. Digital pressure monitoring systems provide precise control and multiple cooking settings through electronic sensors and displays, offering enhanced accuracy and convenience for complex recipes. Choosing between the two depends on whether users prioritize simplicity and durability or advanced features and programmability in their pressure-cooking experience.

Table of Comparison

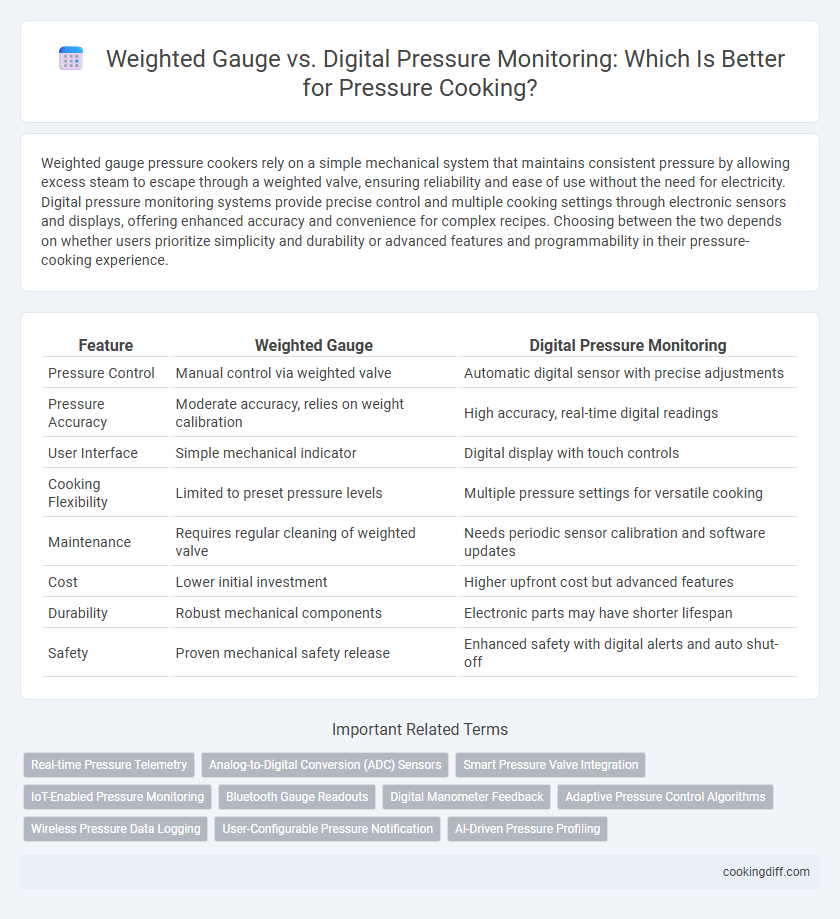

| Feature | Weighted Gauge | Digital Pressure Monitoring |

|---|---|---|

| Pressure Control | Manual control via weighted valve | Automatic digital sensor with precise adjustments |

| Pressure Accuracy | Moderate accuracy, relies on weight calibration | High accuracy, real-time digital readings |

| User Interface | Simple mechanical indicator | Digital display with touch controls |

| Cooking Flexibility | Limited to preset pressure levels | Multiple pressure settings for versatile cooking |

| Maintenance | Requires regular cleaning of weighted valve | Needs periodic sensor calibration and software updates |

| Cost | Lower initial investment | Higher upfront cost but advanced features |

| Durability | Robust mechanical components | Electronic parts may have shorter lifespan |

| Safety | Proven mechanical safety release | Enhanced safety with digital alerts and auto shut-off |

Introduction to Pressure-Cooking Monitoring Methods

| Weighted gauge pressure cookers use a simple, mechanical system with a weighted valve to regulate pressure by releasing steam when it reaches a set level, ensuring consistent cooking pressure. |

| Digital pressure monitoring in modern cookers employs electronic sensors and microprocessors to provide precise pressure readings and adaptive control for optimal cooking results. |

| Both weighted gauge and digital methods offer reliable pressure control, but digital systems enhance accuracy and user convenience through real-time monitoring and customizable settings. |

Overview of Weighted Gauge Pressure Monitoring

Weighted gauge pressure monitoring in pressure cooking relies on a mechanical valve that regulates internal steam pressure by rocking or jiggling to maintain consistent pressure levels. This method provides a simple, reliable way to control cooking pressure without electronic components.

- Mechanical Operation - Uses a weighted valve to release excess steam when pressure exceeds the set level.

- Durability - Resistant to power outages and electronic failures due to its manual design.

- Pressure Accuracy - Generally offers less precise pressure control compared to digital sensors.

Weighted gauge systems remain popular for their straightforward functionality and long-lasting performance in pressure-cooking applications.

Exploring Digital Pressure Monitoring Systems

Digital pressure monitoring systems provide precise and continuous pressure readings, enhancing the safety and efficiency of pressure-cooking. These systems often include programmable settings and alerts, allowing users to maintain optimal cooking conditions.

Weighted gauge pressure cookers rely on a mechanical weight to regulate pressure, which can be less accurate and slower to respond to pressure fluctuations. Digital systems use sensors and microprocessors to monitor pressure in real-time, offering greater control and consistency. This technology improves cooking accuracy, reduces the risk of overcooking, and allows for customizable cooking programs tailored to specific recipes.

Accuracy: Weighted Gauge vs Digital Pressure Monitoring

Weighted gauge pressure cookers rely on a physical weight to maintain pressure, often resulting in consistent but less precise pressure levels compared to digital systems. Digital pressure monitoring offers enhanced accuracy by continuously measuring pressure and displaying real-time data for precise control.

- Weighted Gauge Consistency - Maintains pressure through a weighted valve that regulates steam release at set pressure levels.

- Digital Pressure Accuracy - Uses electronic sensors to provide exact pressure readings and adjust cooking parameters automatically.

- Impact on Cooking Precision - Digital systems allow finer control over pressure, improving cooking results for sensitive recipes.

Ease of Use and User Experience

Weighted gauge pressure cookers provide a simple, mechanical method that users can easily monitor by listening for the characteristic hissing sound, making them intuitive for beginners. Digital pressure monitors offer precise control with easy-to-read displays and customizable settings, enhancing convenience for experienced cooks who prefer accuracy. The choice between these systems impacts user experience by balancing straightforward operation against advanced features and real-time feedback.

Maintenance and Durability Comparisons

Weighted gauge pressure cookers feature simple mechanical parts that require minimal maintenance and are highly durable, often lasting decades without needing replacements. Their robust design withstands frequent use and high temperatures, reducing the risk of malfunctions compared to digital components.

Digital pressure monitoring systems demand regular software updates and sensor calibration to maintain accuracy, increasing maintenance complexity. Although digital models offer precise control, their electronic components may degrade faster under constant heat and pressure, potentially reducing overall lifespan.

Safety Considerations in Pressure Monitoring

Which pressure monitoring method offers greater safety during pressure cooking? Weighted gauge systems provide reliable, mechanical pressure regulation that reduces the risk of failure due to electrical malfunction. Digital pressure monitoring offers precise control and alerts but depends on electronic components that may require regular maintenance to ensure safety.

Cost and Accessibility Analysis

Weighted gauge pressure cookers typically cost less and are easier to maintain, making them accessible for budget-conscious users. Digital pressure monitoring systems offer precise control but come at a higher price point and may require more complex repairs.

- Cost Efficiency - Weighted gauges provide a cost-effective option for reliable pressure management under $50.

- Precision Control - Digital systems can exceed $150, offering exact pressure settings and real-time monitoring.

- Accessibility - Weighted gauges are widely available and straightforward, while digital models may have limited availability and require technical knowledge for usage and maintenance.

Ideal Use Cases for Each Pressure Monitoring Method

Weighted gauge pressure cookers excel in traditional stovetop use, providing reliable pressure regulation through a simple, mechanical weighted valve that maintains consistent cooking pressure ideal for slow-cooked meals and batch cooking. Their durability and lack of electronic components make them perfect for outdoor or off-grid cooking scenarios where power sources are unavailable.

Digital pressure monitoring systems offer precise pressure control and real-time feedback, making them suitable for modern electric pressure cookers and recipes requiring exact pressure settings, such as delicate desserts or quick-cooking grains. These systems often include programmable features and safety sensors, appealing to users who value convenience, accuracy, and multifaceted cooking functionality.

Related Important Terms

Real-time Pressure Telemetry

Weighted gauge pressure cookers provide real-time pressure telemetry through a mechanical system that regulates steam release visually and audibly, ensuring constant pressure levels during cooking. Digital pressure monitoring systems offer precise, continuous pressure readings with integrated sensors and display units, enabling more accurate control and safety for modern pressure-cooking applications.

Analog-to-Digital Conversion (ADC) Sensors

Weighted gauge pressure cookers rely on mechanical regulation by releasing steam at set weights, whereas digital pressure cookers use Analog-to-Digital Conversion (ADC) sensors to provide precise pressure readings and more accurate temperature control. ADC sensors convert analog pressure signals into digital data, enabling microprocessor-based adjustments that enhance cooking consistency and safety.

Smart Pressure Valve Integration

Weighted gauge pressure cookers rely on a mechanical valve to maintain consistent pressure through weight adjustments, offering simplicity and reliability without electronic components. Digital pressure monitoring integrates smart pressure valves that enable precise control, real-time pressure tracking, and automated safety features, enhancing cooking accuracy and user convenience in modern pressure-cooking appliances.

IoT-Enabled Pressure Monitoring

IoT-enabled pressure monitoring integrates digital sensors and wireless connectivity for real-time data tracking, providing precise and remote control over pressure-cooking compared to traditional weighted gauge systems that rely on manual pressure regulation. Digital pressure monitoring enhances safety, efficiency, and automation by transmitting pressure metrics to smart devices, enabling predictive maintenance and seamless integration with smart kitchen ecosystems.

Bluetooth Gauge Readouts

Bluetooth gauge readouts in digital pressure monitoring offer precise and real-time pressure data, enhancing control over cooking processes compared to traditional weighted gauge methods. Integrating Bluetooth technology allows seamless remote monitoring and alerts, increasing safety and convenience in pressure-cooking applications.

Digital Manometer Feedback

Digital manometer feedback in pressure-cooking offers precise real-time pressure readings, enhancing safety and cooking accuracy compared to weighted gauge systems. The digital pressure monitoring provides customizable alerts and data logging features, facilitating better control over cooking processes and consistent food results.

Adaptive Pressure Control Algorithms

Adaptive pressure control algorithms enhance digital pressure monitoring by continuously adjusting cooking pressure based on real-time sensor data, offering precise and consistent results compared to the static pressure maintenance of weighted gauge systems. These algorithms optimize cooking times and safety by dynamically responding to variations in temperature and pressure, improving overall efficiency in pressure-cooking.

Wireless Pressure Data Logging

Wireless pressure data logging enhances digital pressure monitoring by providing real-time, precise pressure readings without manual intervention, unlike weighted gauge systems that rely on visual indicators and physical weight adjustments. This technology enables seamless pressure tracking, increased safety, and improved cooking consistency through remote access and automated data collection.

User-Configurable Pressure Notification

Weighted gauge pressure cookers use a physical weight to release steam at a set pressure, providing a tactile and audible notification when the desired pressure is reached, while digital pressure monitoring systems offer user-configurable pressure notifications through precise sensors and customizable alerts for more accurate and versatile cooking control. Digital monitors allow users to set specific pressure levels and receive real-time feedback, enhancing safety and convenience compared to the traditional weighted gauge mechanism.

Weighted Gauge vs Digital Pressure Monitoring for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com