Enamelware pans offer excellent heat retention and a non-reactive surface that prevents food from absorbing metal flavors, making them ideal for slow and even roasting of pet food. Aluminized steel pans heat up quickly and provide superior heat distribution but may react with acidic ingredients, potentially affecting the taste and quality of the roasted pet food. For consistent roasting results and easy cleanup, enamelware pans are preferred, while aluminized steel pans excel in speed and responsiveness.

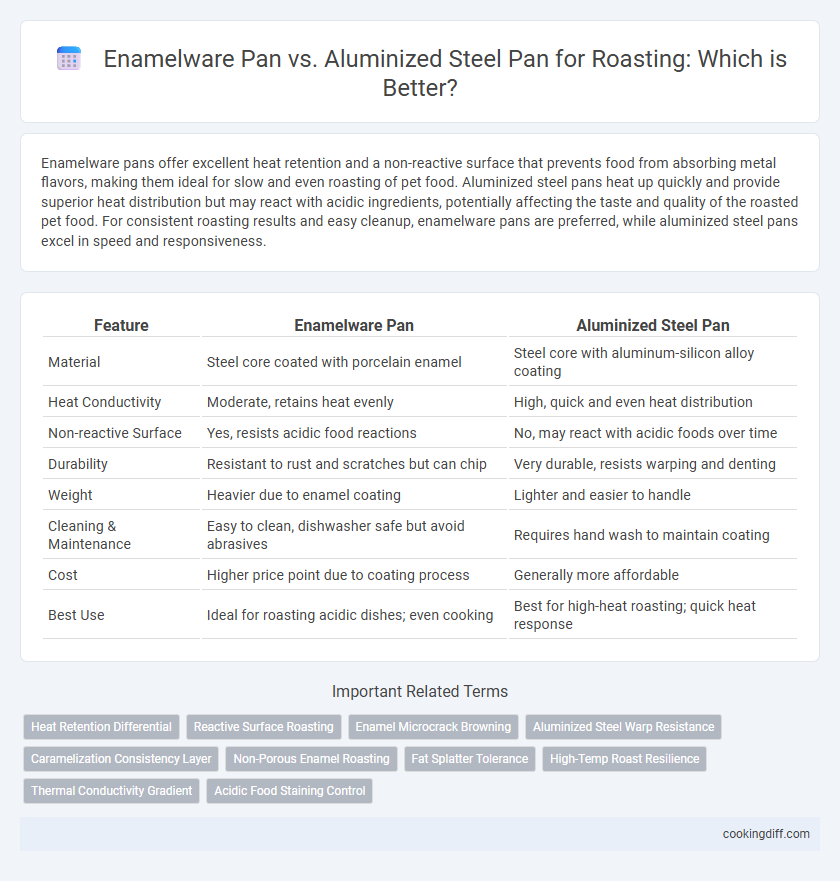

Table of Comparison

| Feature | Enamelware Pan | Aluminized Steel Pan |

|---|---|---|

| Material | Steel core coated with porcelain enamel | Steel core with aluminum-silicon alloy coating |

| Heat Conductivity | Moderate, retains heat evenly | High, quick and even heat distribution |

| Non-reactive Surface | Yes, resists acidic food reactions | No, may react with acidic foods over time |

| Durability | Resistant to rust and scratches but can chip | Very durable, resists warping and denting |

| Weight | Heavier due to enamel coating | Lighter and easier to handle |

| Cleaning & Maintenance | Easy to clean, dishwasher safe but avoid abrasives | Requires hand wash to maintain coating |

| Cost | Higher price point due to coating process | Generally more affordable |

| Best Use | Ideal for roasting acidic dishes; even cooking | Best for high-heat roasting; quick heat response |

Introduction to Roasting: Why Pan Material Matters

Roasting requires even heat distribution and durability, making pan material a critical factor in achieving perfect results. Enamelware pans offer a non-reactive surface that prevents metal flavors from leaching into food, while aluminized steel pans provide excellent heat conductivity and resistance to warping.

Enamelware pans excel in maintaining stable roasting temperatures, essential for caramelization and browning. Aluminized steel pans heat quickly and evenly, reducing hot spots that can cause uneven cooking. Choosing between these materials depends on preference for heat retention versus responsiveness and the type of roasting food.

What is Enamelware? Properties and Features

Enamelware is a type of cookware made by fusing powdered glass to a metal base, creating a smooth, durable, and non-reactive surface ideal for roasting. Its porcelain-coated finish resists rust, stains, and scratches while offering excellent heat retention and even cooking. Unlike aluminized steel pans, enamelware does not impart metallic flavors, ensuring food retains its natural taste during roasting.

What is Aluminized Steel? Properties and Features

What is aluminized steel and why is it used for roasting pans? Aluminized steel is a composite material featuring a steel core coated with an aluminum-silicon alloy, offering enhanced heat conductivity and corrosion resistance. These properties make aluminized steel pans durable, distribute heat evenly during roasting, and prevent rusting, ensuring consistent cooking performance.

Heat Conduction: Enamelware vs Aluminized Steel

Enamelware pans feature a steel core coated with vitreous enamel, providing moderate heat conduction and even roasting temperatures. Their smooth surface resists sticking and is ideal for slow, controlled cooking without hot spots.

Aluminized steel pans combine aluminum's high thermal conductivity with steel's strength, offering rapid and uniform heat distribution for efficient roasting. This material quickly responds to temperature changes, making it suitable for searing and roasting tasks requiring precise heat control.

Durability and Longevity: Which Pan Lasts Longer?

Enamelware pans offer excellent resistance to rust and corrosion, significantly enhancing their durability for long-term use. Aluminized steel pans provide strong structural integrity but may be prone to wear and chipping over time, reducing their lifespan.

- Enamelware Rust Resistance - The enamel coating prevents oxidation, making the pan suitable for prolonged exposure to moisture and acidic foods.

- Aluminized Steel Structural Strength - The steel core delivers robustness but lacks the protective coating, exposing it to potential corrosion.

- Longevity Comparison - Enamelware pans generally outlast aluminized steel pans due to their superior resistance to surface damage and rust.

Ease of Cleaning: Comparing Pan Maintenance

| Pan Type | Ease of Cleaning | Maintenance Considerations |

|---|---|---|

| Enamelware Pan | Non-porous, smooth surface prevents food from sticking, making it simple to wipe clean with minimal scrubbing required. | Resistant to rust and stains, though care must be taken to avoid chipping the enamel coating which could compromise ease of cleaning. |

| Aluminized Steel Pan | Can develop baked-on residue more easily, requiring soaking and scrubbing with abrasive cleaners for thorough cleaning. | Prone to developing discoloration or surface wear over time, which might increase cleaning time and impact pan longevity. |

Weight and Handling: User Experience Differences

Enamelware pans tend to be heavier, providing a sturdy feel but may cause fatigue during prolonged handling. Aluminized steel pans are lighter, allowing easier maneuverability and quicker heat adjustment for roasting.

- Weight Advantage - Aluminized steel pans are significantly lighter, enhancing ease of movement in the kitchen.

- Heat Retention - Enamelware pans maintain heat longer due to their heavier mass, benefiting slow roasting.

- Grip and Handling - Enamelware's weight can offer stability but might be cumbersome when lifting heavy foods.

Choosing between enamelware and aluminized steel pans depends on user preference for weight and ease of handling during roasting.

Flavor Impact: Does Pan Material Affect Taste?

Enamelware pans provide a non-reactive surface that preserves the natural flavors of roasted foods, preventing metallic tastes or chemical reactions during cooking. This results in a cleaner, more authentic flavor profile, especially important for acidic or delicate ingredients.

Aluminized steel pans conduct heat efficiently but can sometimes impart a slight metallic taste if the surface is scratched or worn. However, their excellent heat distribution promotes even roasting, enhancing caramelization and Maillard reactions for deeper, more complex flavors.

Price Comparison: Enamelware vs Aluminized Steel

Enamelware pans typically cost more upfront than aluminized steel pans, with prices averaging between $30 to $70 compared to $15 to $40 for aluminized steel options. The higher price of enamelware reflects its durability, non-reactive surface, and aesthetic appeal, making it a preferred choice for slow roasting. Aluminized steel pans offer excellent heat conduction at a lower price, appealing to budget-conscious home cooks prioritizing performance over appearance.

Related Important Terms

Heat Retention Differential

Enamelware pans have a thicker, porcelain-coated surface that provides superior heat retention and even distribution compared to aluminized steel pans, which tend to heat up and cool down quickly due to their thinner metal construction. This thermal stability in enamelware pans ensures consistent roasting temperatures, resulting in evenly cooked food and reduced risk of hot spots.

Reactive Surface Roasting

Enamelware pans provide a non-reactive surface ideal for roasting acidic or flavorful foods without imparting metallic tastes, preserving the original dish's flavor profile. Aluminized steel pans, while durable and heat-conductive, feature a reactive surface that can alter the taste of acidic ingredients and may cause discoloration during high-temperature roasting.

Enamel Microcrack Browning

Enamelware pans offer a non-reactive surface that prevents food from absorbing metallic flavors during roasting, but their microcracks can harbor residue, leading to uneven browning and potential staining over time. Aluminized steel pans provide superior heat conductivity and durability for consistent roasting results without the risk of enamel microcrack browning issues.

Aluminized Steel Warp Resistance

Aluminized steel pans offer superior warp resistance compared to enamelware, maintaining structural integrity under high roasting temperatures due to their reinforced steel core and aluminum alloy coating. This durability ensures even heat distribution and consistent cooking results, making aluminized steel pans ideal for heavy-duty roasting tasks.

Caramelization Consistency Layer

Enamelware pans provide a smooth, non-reactive surface that promotes even caramelization, preventing hot spots and ensuring consistent browning during roasting. In contrast, aluminized steel pans, with their conductive core and steel surface, heat rapidly but may develop uneven caramelization layers due to variations in heat distribution and surface reactivity.

Non-Porous Enamel Roasting

Non-porous enamel roasting pans offer a smooth, glass-like surface that resists staining and absorbs no odors, ensuring consistent heat distribution and easy cleanup compared to aluminized steel pans. The enamel coating prevents food from sticking and enhances durability, making it ideal for roasting without compromising flavor or pan integrity.

Fat Splatter Tolerance

Enamelware pans offer superior fat splatter tolerance due to their non-porous, smooth surfaces that resist sticking and make cleanup easier during roasting. Aluminized steel pans provide excellent heat conduction but tend to allow more fat splatter, requiring frequent cleaning to maintain optimal performance.

High-Temp Roast Resilience

Enamelware pans offer exceptional high-temp roast resilience due to their durable, non-reactive coating that withstands temperatures up to 500degF without warping or leaching, ensuring even heat distribution and consistent browning. In contrast, aluminized steel pans, while providing good heat conductivity and resistance to rust, may lose structural integrity and warp under prolonged exposure to extreme roasting temperatures above 450degF.

Thermal Conductivity Gradient

Enamelware pans offer moderate thermal conductivity with a protective coating that evenly distributes heat but may retain less heat compared to aluminized steel pans, which combine the high thermal conductivity of aluminum with the durability of steel for rapid, consistent roasting temperatures. The thermal conductivity gradient in aluminized steel pans ensures faster heat transfer and more uniform roasting results, while enamelware pans provide gentler heat suitable for slow roasting processes.

Enamelware pan vs Aluminized steel pan for roasting. Infographic

cookingdiff.com

cookingdiff.com